Wobble Socket Extension

Here’s your well-structured, engaging blog post on Wobble Socket Extensions formatted in clean HTML:

Step-by-Step Process

Inspect Socket Fit

Check if the wobble socket fits securely on the extension.

Align Extension

Ensure the extension is aligned with the tool's axis.

Tighten Securely

Tighten the socket to prevent slippage during use.

Test Functionality

Verify the socket extension works smoothly with the tool.

Lubricate if Needed

Apply grease to reduce friction and wear.

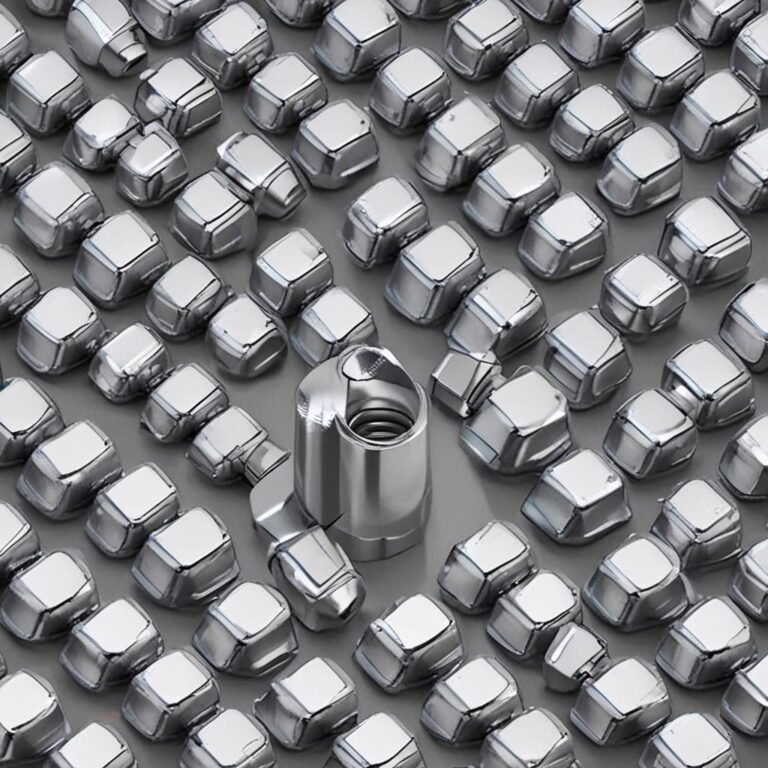

Process infographic for Wobble Socket Extension

—

Tight spaces, awkward angles, and hard-to-reach bolts can turn a simple repair into a frustrating challenge. Whether you’re a mechanic, DIY enthusiast, or homeowner, the wobble socket extension is a game-changer. This versatile tool allows you to access fasteners in confined areas with ease, saving time and effort. In this guide, we’ll explore what a wobble socket extension is, its benefits, how to choose the right one, and expert tips for using it effectively.

What is a Wobble Socket Extension?

Definition and Key Features

A wobble socket extension is a mechanical tool designed to reach fasteners in tight or angled spaces. Its standout feature is a pivoting head that swivels (typically 45°–60°) to access bolts and nuts from multiple directions. This flexibility is a huge advantage over rigid standard extensions.

Components of a Wobble Socket Extension

A wobble extension consists of several key parts:

- Socket drive: Connects to your ratchet or wrench.

- Pivoting head: Allows multidirectional movement.

- Ratchet interface: Ensures secure attachment.

- Locking mechanism: Some models let you lock the head in place.

How It Differs from Standard Socket Extensions

Unlike rigid extensions that require precise alignment, a wobble extension adapts to your workspace. While standard extensions are great for straight access, the wobble design shines in confined or angled areas, reducing the need for excessive repositioning.

Benefits of Using a Wobble Socket Extension

Enhanced Versatility in Tight or Awkward Spaces

The pivoting head lets you work in cramped areas like engine compartments, plumbing systems, or behind furniture. No more struggling with rigid tools—just angle the wobble extension and get the job done.

Reduces Risk of Damage to Fasteners and Tools

Because the wobble head distributes torque more evenly, it minimizes the risk of stripping bolts or snapping sockets. This makes it ideal for delicate repairs where precision matters.

Saves Time and Effort

With a standard extension, you’d constantly adjust your position to align the socket. A wobble extension eliminates this hassle, letting you focus on tightening or loosening fasteners efficiently.

How to Choose the Right Wobble Socket Extension

Consider the Angle of Pivoting Range

Most wobble extensions pivot between 45° and 60°. Choose a wider range (e.g., 60°) for extremely tight spaces, while a 45° model may suffice for general use.

Evaluate Material and Durability

Opt for high-quality steel (like chrome vanadium) for strength and corrosion resistance. Avoid flimsy materials that may bend or break under pressure.

Determine the Appropriate Length and Drive Size

Common lengths range from 6 inches to 36 inches. For automotive work, 12–18 inches is ideal. Drive sizes (1/4”, 3/8”, 1/2”) must match your ratchet and sockets.

Check Compatibility with Your Ratchet and Sockets

Ensure the extension’s square drive fits your tools. Most use standard sizes, but always verify before purchasing.

Techniques for Using a Wobble Socket Extension

Proper Positioning and Alignment

Angle the wobble head toward the fastener before inserting the socket. Apply gentle pressure to keep it centered.

Applying Pressure and Torque

Use steady, even force. Avoid over-tightening, as this can strain the pivot mechanism.

Combining with Universal Joints or Extensions

For maximum reach, pair the wobble extension with a universal joint or additional extensions—but avoid overloading the tool.

Common Mistakes to Avoid

Don’t overextend the pivot range, use mismatched sockets, or force the tool at extreme angles. These can lead to slipping or damage.

Applications of Wobble Socket Extensions

Automotive Repairs

Perfect for engine work, suspension repairs, or tire changes where space is limited.

Plumbing and HVAC Systems

Access bolts in narrow pipes or behind ductwork without disassembling components.

Construction and Industrial Settings

Useful for tight spaces in electrical panels, machinery, or structural frameworks.

Home Improvement Projects

Assemble furniture, fix appliances, or repair garden equipment with ease.

Maintenance and Care Tips

Cleaning and Lubrication

Remove debris from the pivot points and apply a light lubricant to maintain smooth operation.

Storing to Prevent Wear

Store in a toolbox or hanging rack to avoid bending. Keep away from moisture.

Regular Inspection for Damage

Check for cracks, warping, or excessive play in the pivot regularly.

FAQs About Wobble Socket Extensions

What is the difference between a wobble socket extension and a standard extension?

A wobble extension swivels for multidirectional access, while standard extensions are rigid.

What is the maximum angle a wobble socket extension can pivot?

Most models pivot 45°–60°, depending on the design.

Can wobble socket extensions be used with all socket sizes?

Yes, but ensure the socket’s drive size matches the extension’s interface.

How often should I maintain my wobble socket extension?

Clean and lubricate after 10–15 uses, especially in corrosive environments.

Are wobble socket extensions worth the investment?

Absolutely—investing in a high-quality wobble extension saves time and frustration for professionals and DIYers alike.

Conclusion

A wobble socket extension is a must-have for anyone tackling tight spaces or awkward angles. Its versatility, durability, and time-saving benefits make it a worthwhile addition to your toolkit. Ready to tackle those hard-to-reach bolts? Grab a wobble extension and get to work. Have questions or tips? Share them in the comments!

—