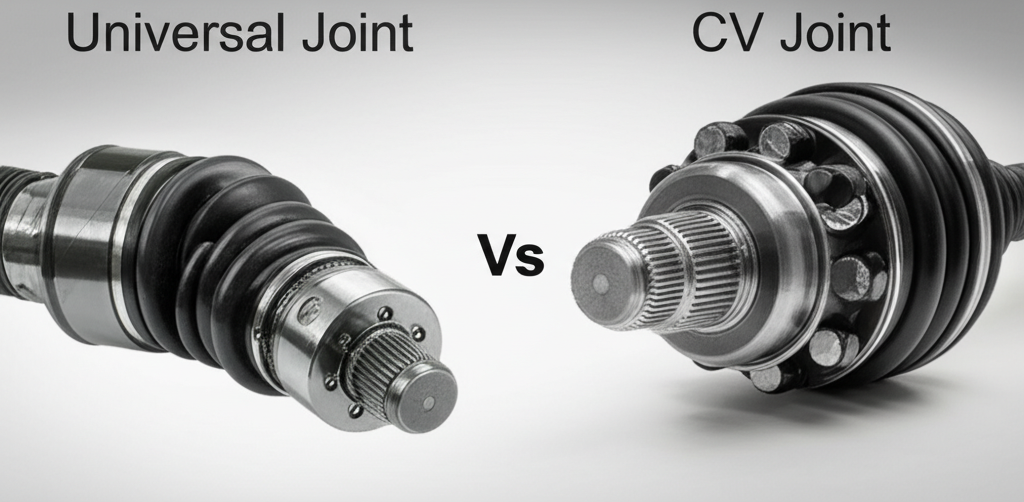

Universal Joint Vs Cv Joint

When it comes to automotive drivetrains, two critical components—universal joints (U-joints) and constant velocity (CV) joints—play a vital role in ensuring smooth power transmission. Whether you’re a car enthusiast, a mechanic, or someone looking to understand your vehicle better, knowing the differences between these joints is essential for proper maintenance and performance. While U-joints are simple, cost-effective solutions for transmitting rotational force between misaligned shafts, CV joints offer smoother operation and are ideal for modern front-wheel-drive and all-wheel-drive systems. This blog post dives into the key differences, functions, and applications of U-joints and CV joints, helping you make informed decisions for your vehicle.

What is a Universal Joint (U-Joint)?

Definition and Basic Function

A universal joint, or U-joint, is a mechanical coupling that transmits rotational motion between two shafts that are not aligned. It accommodates angular misalignment by allowing the shafts to rotate independently while maintaining a connection. This flexibility makes U-joints indispensable in applications where shafts must pivot relative to each other, such as in driveshafts and industrial machinery.

Construction and Components

A typical U-joint consists of a cross-shaped component (the cross), needle bearings, and yokes that attach to the shafts. The cross houses the bearings, which reduce friction as the joint rotates. The yokes, which are fork-shaped, connect the cross to the shafts, allowing them to pivot. This design ensures smooth rotation even when the shafts are at different angles.

Types of Universal Joints

U-joints come in two primary types: single and double cardan (CV) U-joints. Single U-joints are the most common and are used in simple driveshaft applications. Double cardan joints, however, feature an intermediate shaft with two U-joints to minimize speed fluctuations. These joints are often found in heavy-duty vehicles and industrial equipment.

Advantages and Limitations

U-joints offer several benefits, including a simple and robust design, low cost, and high torque capacity. However, they have limitations, such as speed variations (due to changing angles) and potential vibrations at high speeds. Additionally, U-joints have a limited articulation range, making them less suitable for applications requiring extensive movement.

What is a Constant Velocity (CV) Joint?

Definition and Basic Function

A constant velocity (CV) joint is designed to transfer rotational power from the transmission to the wheels while maintaining a constant speed, even at varying angles. Unlike U-joints, CV joints eliminate speed fluctuations, making them ideal for front-wheel-drive and all-wheel-drive vehicles. This smooth operation enhances drivability and reduces wear on drivetrain components.

Construction and Components

CV joints consist of an inner race, outer race, bearings (usually balls), and a cage that holds the bearings in place. The most common designs are the Rzeppa and tripod types. In a Rzeppa joint, balls are arranged in a circular pattern within the cage, allowing for smooth rotation at various angles. Tripod joints, on the other hand, use three rollers instead of balls, making them better suited for certain applications.

Key Metrics

Performance metrics for Universal Joint Vs Cv Joint

Types of CV Joints

CV joints are classified into several types, including Rzeppa, tripod, fixed, and plunge joints. Rzeppa joints are widely used in front-wheel-drive vehicles due to their ability to handle both angular and axial movement. Tripod joints are commonly found on the inner side of axles, while fixed joints are used where the angle remains constant. Plunge joints accommodate varying lengths of the driveshaft, such as in the inner CV joints of front-wheel-drive cars.

Advantages and Limitations

CV joints provide significant advantages, including smooth operation, constant rotational speed, and better articulation compared to U-joints. However, they are more complex and expensive to manufacture. Additionally, CV joints rely on protective boots to retain lubrication, and if these boots tear, contaminants can enter, leading to premature wear and failure.

Key Differences Between U-Joints and CV Joints

Speed and Torque Transmission

One of the most significant differences between U-joints and CV joints is how they transmit speed and torque. U-joints cause speed variations as the angle between shafts changes, leading to potential vibrations. In contrast, CV joints maintain a constant rotational speed, ensuring smoother performance. While both joints can handle high torque, CV joints are generally more efficient in transmitting power at varying angles.

Design and Flexibility

U-joints are designed to accommodate large misalignments but are limited in their range of motion. CV joints, however, provide better articulation and smoother operation, making them ideal for applications requiring extensive movement, such as steering and suspension systems. The ball-and-cage design of CV joints allows for more precise control over rotational speed and angle.

Durability and Maintenance

U-joints typically require regular greasing to reduce friction and extend lifespan. CV joints, on the other hand, rely on sealed boots filled with grease, which must be inspected for cracks or tears. While U-joints are generally more durable in high-torque applications, CV joints offer better performance in dynamic environments. Common signs of failure include vibrations, clunking noises, and grease leaks.

Cost and Availability

U-joints are generally less expensive and easier to replace than CV joints. Their simple design makes them a cost-effective solution for many applications. CV joints, however, are more complex and costly due to their precision engineering. Despite the higher price, CV joints provide superior performance, making them a worthwhile investment for modern vehicles.

When to Use a U-Joint vs. a CV Joint

Applications in Vehicles

U-joints are commonly used in rear-wheel-drive vehicles and industrial machinery where simplicity and robustness are prioritized. CV joints, on the other hand, are essential in front-wheel-drive and all-wheel-drive systems, where smooth power delivery and precise steering are crucial. The choice between the two depends on the vehicle’s drivetrain configuration and performance requirements.

Performance Considerations

U-joints are best suited for high-torque, low-speed applications, such as in trucks and heavy machinery. CV joints excel in precision applications, such as front-wheel-drive cars and SUVs, where smooth and efficient power transfer is essential. Understanding these performance differences ensures you select the right joint for your specific needs.

Conclusion

Both universal joints and constant velocity joints play crucial roles in automotive drivetrains, but they serve different purposes. U-joints offer simplicity and cost-effectiveness, making them ideal for rear-wheel-drive and industrial applications. CV joints, meanwhile, provide smoother operation and better articulation, making them indispensable in modern front-wheel-drive and all-wheel-drive vehicles. By understanding the key differences between these joints, you can make informed decisions about maintenance, repairs, and upgrades, ensuring optimal performance and longevity for your vehicle.

FAQ Section

Q1: Can a U-joint be replaced with a CV joint?

In most cases, U-joints and CV joints are not interchangeable due to their different functions and designs. However, some specialized adapters or custom solutions may exist for specific applications. Always consult a professional mechanic to determine compatibility.

Q2: How often should U-joints and CV joints be inspected?

U-joints should be inspected and greased every 15,000 to 30,000 miles, depending on the vehicle’s usage. CV joints should be checked for boot damage and leaks during regular maintenance, typically every 30,000 to 50,000 miles. Early detection of wear can prevent costly repairs.

Q3: What are the signs of a failing U-joint or CV joint?

Common signs of a failing U-joint include vibrations, clunking noises when shifting gears, and excessive grease leakage. A failing CV joint may produce clicking or popping sounds when turning, vibrations at certain speeds, or grease leaks from the torn boot. Addressing these symptoms promptly can prevent further damage.

Q4: Are CV joints more expensive than U-joints?

Yes, CV joints are generally more expensive than U-joints due to their complex design and precision engineering. Replacement parts and labor costs for CV joints are higher, but their superior performance justifies the investment in many applications.

Q5: Can CV joints be repaired, or do they need full replacement?

Minor issues, such as a torn boot, can sometimes be repaired by replacing the boot and repacking the joint with grease. However, if the bearings or races are damaged, the entire CV joint must be replaced. Regular inspections and maintenance can prolong the lifespan of CV joints and prevent costly replacements.