Universal Joint Socket Wrench Attachment

When it comes to tackling automotive repairs, plumbing tasks, or machinery maintenance, having the right tools can make all the difference. One such indispensable tool is the universal joint socket wrench attachment (UJSWA), a specialized adapter designed to access hard-to-reach fasteners with ease. Whether you’re working on suspension systems, exhaust pipes, or tight corners in HVAC units, this flexible tool ensures precision and efficiency where traditional rigid sockets fall short. Its ability to maneuver at various angles not only saves time but also reduces the need for disassembling components. In this article, we’ll dive into what makes the universal joint socket wrench attachment a must-have, how it works, and how to choose and use it effectively.

Understanding the Universal Joint Socket Wrench Attachment

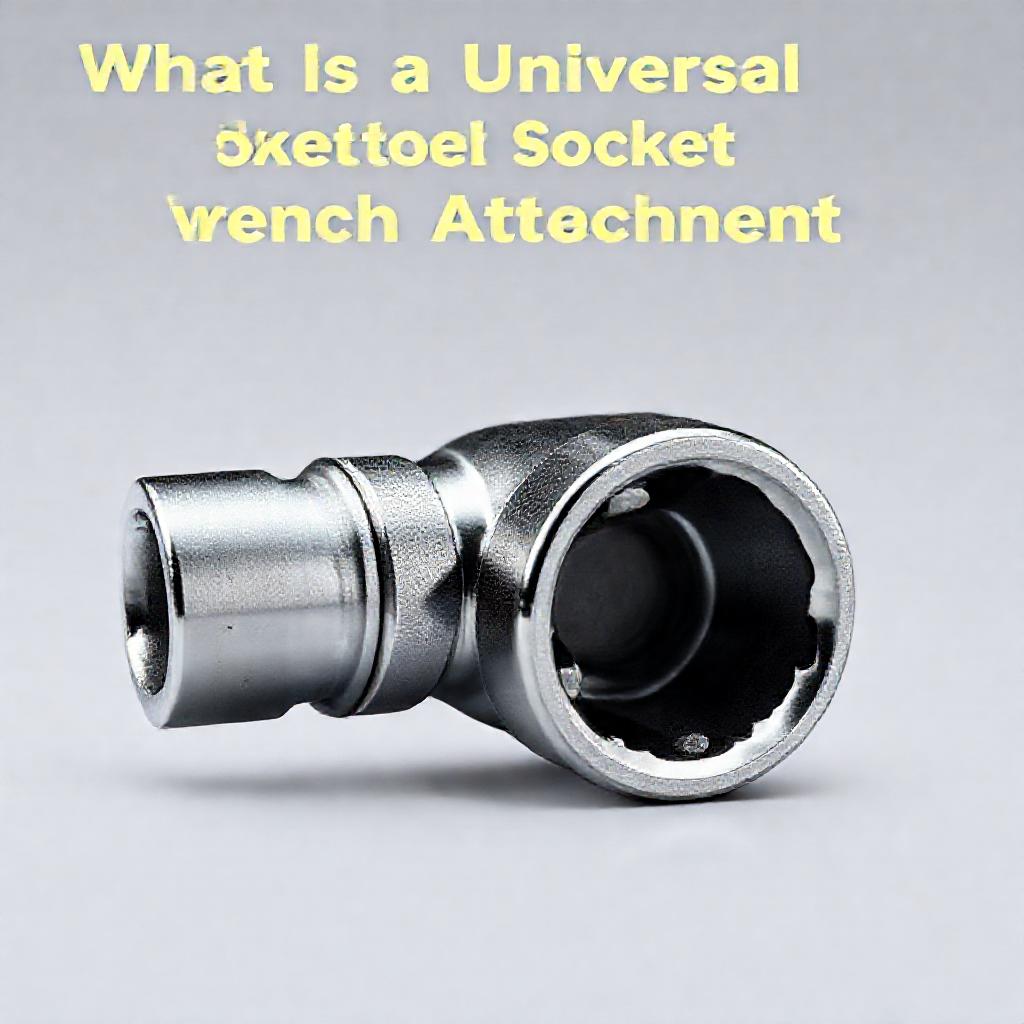

What Is a Universal Joint Socket Wrench Attachment?

A universal joint socket wrench attachment is a socket adapter equipped with a flexible joint mechanism that allows angular movement. Unlike standard socket wrench attachments, which are rigid, the UJSWA’s universal joint enables it to bend and pivot, making it ideal for accessing fasteners in confined or awkward spaces. Its core components include the flexible joint, a socket drive, and compatibility with handles or extensions. This design ensures versatility and adaptability in challenging work environments.

How It Works

The universal joint’s flexibility allows it to move in two planes, transmitting torque to fasteners even when access is limited. This is particularly useful in scenarios where a straight path to the fastener isn’t possible. For example, when working on car engines or machinery with tight clearances, the UJSWA can navigate around obstacles, ensuring efficient and effective tightening or loosening of bolts and nuts.

Applications and Benefits of Using a UJSWA

Common Use Cases

The UJSWA is widely used in automotive repairs, such as accessing spark plugs, CV joints, or brake components. It’s also invaluable in plumbing for tightening pipes in cramped areas and in HVAC or machinery maintenance for reaching fasteners in complex systems. Its versatility makes it a go-to tool for professionals and DIY enthusiasts alike.

Advantages Over Traditional Tools

The UJSWA’s ability to work in confined spaces is its standout feature. It reduces strain by enabling angled access, minimizes the need for disassembling parts, and saves time by allowing multi-angle adjustments. These benefits make it a superior choice compared to traditional rigid socket attachments.

Types and Variations of Universal Joint Socket Attachments

Drive Sizes

UJSWAs come in various drive sizes, including 1/4”, 3/8”, 1/2”, and 3/4”. Each size is suited for different tasks, with smaller drives ideal for precision work and larger drives for heavy-duty applications.

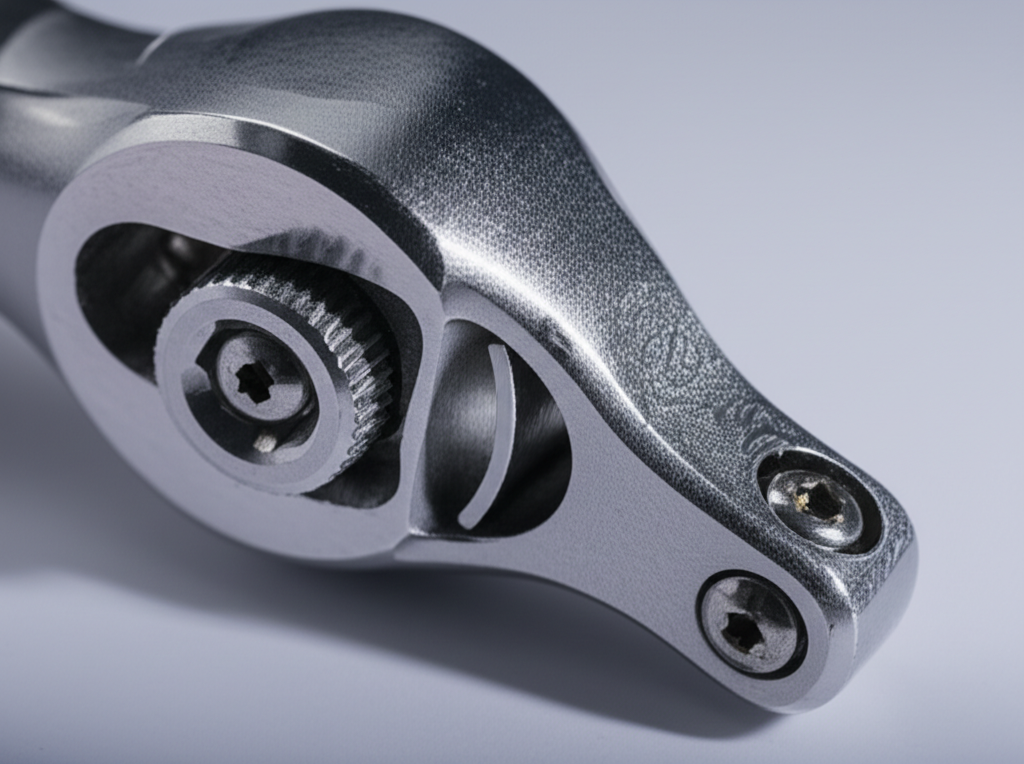

Joint Configurations

Single universal joint attachments are common, but multi-joint or articulated versions offer even greater flexibility. Offset angles, such as 15°, 30°, or 45°, cater to specific needs and enhance accessibility.

Socket Compatibility

UJSWAs are compatible with both standard (SAE) and metric socket sets, ensuring they can handle a wide range of fastener sizes. This compatibility makes them versatile tools for various industries.

Material and Durability

High-quality UJSWAs are typically made from chrome vanadium steel, carbon steel, or heat-treated alloys. Impact-rated versions are available for use with power tools, ensuring durability and longevity.

How to Choose the Right UJSWA for Your Needs

Assessing Your Tool Requirements

Consider factors like space constraints, torque demands, and fastener types when choosing a UJSWA. Ensure it’s compatible with your existing socket wrenches and ratchets for seamless integration into your toolkit.

Key Features to Prioritize

Look for a UJSWA with a high-quality joint that offers smooth movement and resists wear. A wide socket size range, ergonomic design, and ease of use are also essential features to prioritize.

Tips for Using a Universal Joint Socket Wrench Attachment

Proper Technique

Position the tool correctly to avoid binding or stripping fasteners. Apply steady pressure while maintaining control during rotation to ensure efficient and safe operation.

Limitations and Precautions

Avoid using a UJSWA in high-torque situations where the joint may flex excessively. Regularly check for wear or damage to ensure safety and optimal performance.

Maintenance and Longevity

Cleaning and Storage

Clean the joint and sockets after use by removing debris and applying lubrication. Store the tool in a dry place to prevent corrosion or misalignment, ensuring it remains in top condition.

Common Issues and Fixes

If the joint becomes sticky or the socket slips, clean or replace the affected components. Regular maintenance and timely replacements will extend the tool’s lifespan.

Comparison With Similar Tools

UJSWA vs. Standard Sockets

While standard sockets are ideal for straightforward torque delivery, UJSWAs excel in flexibility and accessibility. Each tool has its situational pros and cons, making them complementary rather than interchangeable.

UJSWA vs. Flex-Head Ratchets

Comparison table for UJSWA vs. Flex-Head Ratchets

Flex-head ratchets offer similar flexibility but differ in design and use cases. UJSWAs are better for tight corners, while flex-head ratchets are suited for deep-well applications.

Conclusion

The universal joint socket wrench attachment is a game-changer for anyone dealing with hard-to-reach fasteners. Its flexibility, versatility, and time-saving benefits make it an essential addition to any toolkit. By investing in a high-quality UJSWA and practicing proper usage and maintenance, you can tackle complex jobs with confidence and efficiency. Start with controlled scenarios to familiarize yourself with its capabilities, and you’ll soon wonder how you ever managed without it.

FAQ Section

Can a universal joint socket wrench attachment damage my tools or fasteners?

Misuse, such as applying excessive torque or using it in inappropriate situations, can lead to damage. Proper application ensures safe and effective use.

What sizes are available for universal joint attachments?

Common drive sizes include 1/4”, 3/8”, 1/2”, and 3/4”, with socket dimensions varying based on standard or metric requirements.

Is it compatible with impact wrenches?

Yes, but only impact-rated UJSWAs should be used with impact wrenches to handle the increased torque and prevent damage.

How do I clean and maintain a universal joint attachment?

Regularly clean the joint and sockets, remove debris, and apply lubrication. Store the tool in a dry place to prevent corrosion.

When should I avoid using a universal joint socket wrench?

Avoid using it in high-torque situations or where a rigid tool would provide better stability and control.