Universal Joint Socket Toolstation

Universal joints are vital components in a wide range of mechanical systems, from automotive drivetrains to industrial machinery. Their ability to transmit rotational power through varying angles makes them indispensable, but also subject to wear and tear. Maintaining and repairing these joints efficiently requires specialized tools, and that’s where a universal joint socket toolstation comes in. This article will delve into the world of universal joints and explore how a dedicated toolstation can significantly improve your workflow.

Introduction to Universal Joint Socket Toolstation

Overview of Universal Joints and Their Importance

Universal joints, also known as U-joints, are mechanical components that connect rotating shafts, allowing power transmission even when the shafts are not aligned on the same axis. They are crucial in applications where the angle between the driving and driven shafts changes, such as in the driveshafts of rear-wheel-drive vehicles. Without universal joints, smooth and efficient power transfer would be impossible in many scenarios.

A universal joint socket toolstation is a dedicated workspace designed to facilitate the efficient maintenance, repair, and replacement of universal joints. By providing a secure and organized environment, these toolstations streamline the process, reducing the time and effort required for these tasks.

Understanding Universal Joints

Definition and Functionality

A universal joint is a type of coupling that allows rotation between two shafts that are not in line. It consists of two yokes, one attached to each shaft, connected by a cross-shaped intermediate member called a spider or cross journal. This design enables the joint to transmit torque while accommodating angular misalignment.

Universal joints are typically constructed from hardened steel or other durable materials to withstand the high stresses and demanding conditions in which they operate. The precision of their construction is critical for smooth operation and longevity.

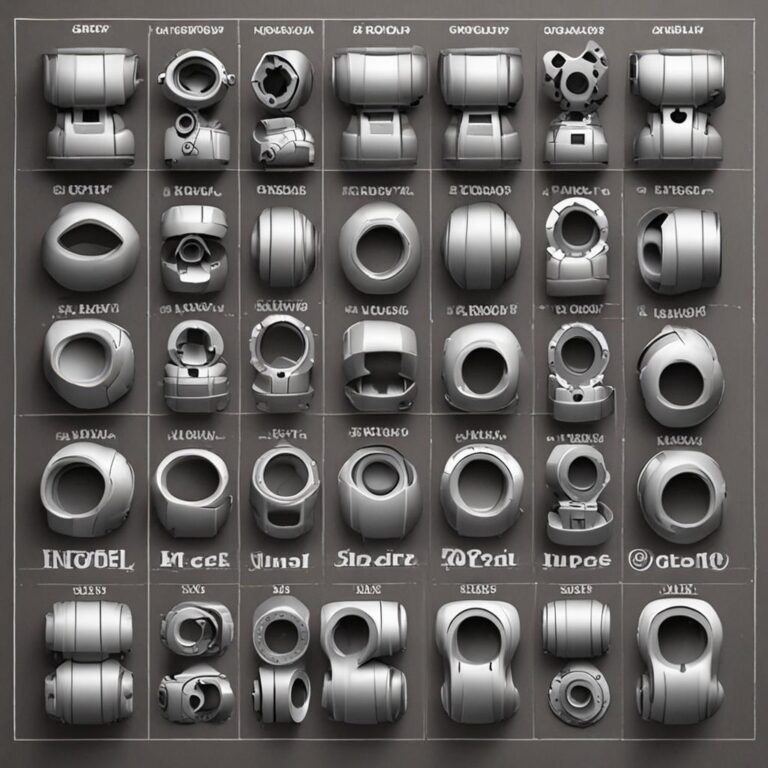

Types of Universal Joints

There are several types of universal joints, each with its own advantages and limitations. The most common type is the single Cardan joint, which is simple and robust but can produce variations in output speed at higher angles. Double Cardan joints consist of two single Cardan joints connected in series, which helps to minimize these speed variations.

Other types include constant velocity (CV) joints, which are more complex but provide a constant output speed regardless of the operating angle. The choice of universal joint depends on the specific application and the required performance characteristics.

The Role of a Universal Joint Socket Toolstation

Introduction to Toolstations

A toolstation is a dedicated workspace designed to organize tools and facilitate specific tasks. Toolstations are commonly found in workshops, garages, and industrial settings, providing a centralized location for tools and equipment.

A universal joint socket toolstation is specifically designed for working with universal joints. It typically includes specialized sockets, wrenches, and other tools needed for disassembly, inspection, and reassembly, along with a sturdy work surface and storage compartments.

Features and Benefits

Features table for Features and Benefits

A universal joint socket toolstation offers several key features, including a durable work surface, organized tool storage, and specialized sockets and wrenches designed for U-joint maintenance. Many toolstations also include a vise or other clamping mechanism to hold the universal joint securely during disassembly and reassembly.

The benefits of using a dedicated toolstation include increased efficiency, reduced risk of damage to components, and improved safety. By having the right tools readily available in an organized workspace, mechanics can complete U-joint repairs more quickly and accurately.

Using a Universal Joint Socket Toolstation

Safety Precautions

Safety is paramount when working with universal joints and toolstations. Always wear appropriate personal protective equipment (PPE), including safety glasses and gloves. Ensure the work area is well-lit and free of obstructions.

Before starting any work, disconnect the power source or disable the equipment to prevent accidental activation. Be careful when handling sharp tools and avoid using excessive force, which can damage components or cause injury.

Step-by-Step Guide

To disassemble a universal joint using a toolstation, first secure the joint in a vise or clamping mechanism. Use the appropriate socket to remove the retaining clips or snap rings that hold the bearing cups in place. Gently tap the bearing cups out of the yoke using a punch or press. Inspect all components for wear or damage.

To reassemble, lubricate the bearing cups and needle bearings with grease. Carefully press the bearing cups back into the yoke, ensuring they are properly seated. Install the retaining clips or snap rings to secure the bearing cups. Double-check that the universal joint moves freely and smoothly.

Maintenance and Care

Cleaning and Storage

To prolong the lifespan of your universal joint socket toolstation, clean it regularly after use. Wipe down the work surface and tools with a clean cloth to remove dirt, grease, and debris. Store the tools in their designated compartments to prevent damage and keep them organized.

Periodically inspect the toolstation for signs of wear or damage, such as loose fasteners or damaged components. Replace any worn or damaged parts promptly to maintain optimal performance.

Troubleshooting Common Issues

Common issues that may arise when using a universal joint socket toolstation include difficulty removing retaining clips, stuck bearing cups, and damaged threads. To remove stubborn retaining clips, try using a penetrating oil or heat. If a bearing cup is stuck, use a press or a specialized tool to gently push it out.

To prevent these issues, lubricate the components before disassembly and use the correct tools for the job. Avoid using excessive force, which can damage the universal joint or the toolstation.

Conclusion

Summary and Recommendations

A universal joint socket toolstation is an invaluable asset for anyone who regularly works with universal joints. By providing a dedicated workspace and specialized tools, these toolstations streamline the maintenance and repair process, improving efficiency, safety, and accuracy.

When choosing a universal joint socket toolstation, consider the type of universal joints you work with, the frequency of use, and the available space in your workshop. Look for a toolstation that is durable, well-organized, and equipped with the necessary tools for your specific needs.

FAQ

Frequently Asked Questions

- What is the primary use of a universal joint socket toolstation?

- How do I choose the right universal joint socket toolstation for my needs?

- Can a universal joint socket toolstation be used for other tasks beyond universal joint maintenance?

- How often should I maintain my universal joint socket toolstation?

- Are universal joint socket toolstations suitable for DIY enthusiasts or professional use only?

The primary use is for the efficient maintenance and repair of universal joints in various applications.

Consider the type of universal joints you work with, the frequency of use, and the available space in your workshop.

While designed specifically for universal joints, some toolstations may offer versatility for related tasks, but it’s essential to check the manufacturer’s recommendations.

Regular cleaning after use and periodic inspection for wear and tear can significantly extend the toolstation’s lifespan.

Both DIY enthusiasts and professionals can benefit from using a universal joint socket toolstation, depending on the complexity of the tasks and the level of precision required.