Universal Joint Explained

When your car accelerates smoothly down the highway or heavy machinery powers through demanding tasks, there’s often a small but mighty component working behind the scenes: the universal joint. Commonly known as a U-joint, this unassuming device plays a crucial role in transmitting power between rotating shafts that aren’t perfectly aligned. Found in everything from rear-wheel-drive vehicles to industrial equipment, the universal joint enables reliable torque transfer even when shafts operate at angles. Despite advancements in drivetrain technology, the U-joint remains a cornerstone of mechanical power transmission—valued for its durability, simplicity, and effectiveness.

Introduction to Universal Joints

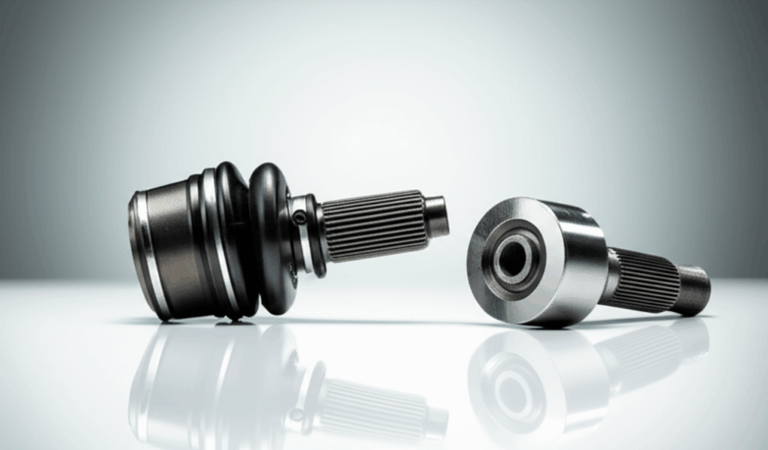

A universal joint, or U-joint, is a mechanical coupling that allows the transmission of rotary motion between two shafts whose axes intersect at an angle. This ability to accommodate angular misalignment makes U-joints indispensable in systems where perfect shaft alignment isn’t possible. The design dates back to the 16th century and is credited to Italian mathematician and engineer Gerolamo Cardano, which is why U-joints are sometimes called Cardan joints.

These components are widely used across various industries. In automotive engineering, they connect the transmission to the rear differential via the driveshaft. They’re also essential in industrial machinery, aircraft control systems, and marine propulsion setups. At their core, universal joints are designed to transmit torque efficiently while allowing for movement and misalignment caused by suspension travel, thermal expansion, or dynamic loads.

How a Universal Joint Works

The basic structure of a universal joint consists of a cross-shaped center piece—commonly referred to as a “spider”—mounted with four arms. Each arm connects to a yoke on either the input or output shaft via needle bearings and bearing caps. As one shaft rotates, the cross transmits motion to the second shaft, even if the two are angled relative to each other.

However, a key characteristic of single U-joints is that they do not deliver constant angular velocity. As the joint articulates, the output shaft speeds up and slows down twice per revolution, creating a non-uniform motion. This phenomenon, known as velocity variation, can lead to vibration and wear if not properly managed.

To counteract this, engineers often use two U-joints in series, properly phased and connected by an intermediate shaft. When aligned correctly—typically with both joints operating at the same angle and oriented 90 degrees out of phase—the speed fluctuations cancel each other out, resulting in smoother power delivery.

Types of Universal Joints

Single Universal Joint

- Comprises one cross and two yokes, forming the most basic U-joint configuration.

Double Cardan (Double U-Joint) Assembly

- Consists of two universal joints linked by a center yoke or intermediate shaft.

Constant Velocity (CV) Joints vs. U-Joints

- While both transmit torque across misaligned shafts, CV joints maintain constant output speed regardless of angle.

Other Variants (e.g., Bendix-Weiss, Spicers, Disc Couplings)

- Specialized U-joint designs like Bendix-Weiss offer enhanced flexibility and reduced vibration in precision applications.

Common Applications of Universal Joints

Automotive Drivetrains

In rear-wheel and four-wheel-drive vehicles, U-joints are critical components of the driveshaft assembly. They connect the transmission’s output shaft to the rear differential, allowing torque to be transmitted despite changes in driveline angle caused by suspension movement. This flexibility ensures uninterrupted power delivery whether the vehicle is accelerating, cornering, or traversing uneven terrain.

Without properly functioning U-joints, drivetrain efficiency drops significantly, leading to vibrations, noise, and potential mechanical failure. Their durability under high torque and variable loads makes them ideal for trucks, off-road vehicles, and performance applications.

Industrial Machinery

Universal joints are widely used in industrial environments where precise power transmission is required despite misalignment. Applications include printing presses, rolling mills, conveyors, and pumps. In these settings, U-joints help absorb minor shaft misalignments caused by thermal expansion, foundation settling, or assembly tolerances.

Their ability to handle high torque and moderate angular deflection makes them suitable for connecting motors to driven equipment without requiring perfect alignment—reducing installation time and mechanical stress.

Aerospace and Marine Systems

In aerospace, U-joints appear in control linkages, rotor drives, and auxiliary power units, where compactness and reliability are paramount. They allow control inputs to be transmitted through complex airframe geometries while maintaining responsiveness.

Marine applications include propeller shafts in boats and ships, where U-joints accommodate hull flexing and engine movement. Their resistance to vibration and ability to operate in corrosive environments (when properly sealed) make them well-suited for demanding nautical conditions.

Signs of a Failing Universal Joint

Recognizing early symptoms of U-joint failure is essential for preventing costly drivetrain damage. One of the most common indicators is a clunking or knocking noise when accelerating or decelerating, especially in manual transmission vehicles. This occurs due to excessive play in the worn joint as torque loads shift.

Vibration at highway speeds is another telltale sign, often increasing with vehicle speed. This results from imbalance caused by worn bearings or a damaged cross. Squeaking noises during motion, particularly at low speeds, may indicate dry or failing needle bearings.

Visually, inspecting the driveshaft may reveal rust trails around bearing caps—evidence of lost lubrication—or visible wobble when manually rotating the shaft. Grease leaking from the seals (in greaseable models) also signals deteriorating seals or over-greasing, which can lead to contamination and accelerated wear.

Maintenance and Replacement Tips

Regular Inspection Procedures

- Periodically check the driveshaft by manually rotating it and rocking it back and forth to detect any play or binding.

Lubrication and Sealing

- Many U-joints feature grease fittings (zerks) that allow periodic lubrication to maintain bearing health.

When to Replace a U-Joint

- At the first sign of play, noise, or vibration, consider replacing the affected U-joint.

Advantages and Limitations of Universal Joints

Features table for Advantages and Limitations of Universal Joints

Universal joints offer several compelling advantages. Their simple, robust design provides high torque transmission capability and resilience in harsh environments. They are relatively inexpensive to manufacture and maintain, making them a cost-effective solution for many mechanical systems. Additionally, they can accommodate significant angular misalignment—often up to 25 degrees—without failure.

However, U-joints also come with limitations. The non-constant velocity output of single joints can induce vibration and noise, especially at high speeds or large angles. They require regular maintenance (in greaseable models) and are prone to wear over time due to metal-on-metal contact. In precision applications, their inherent speed fluctuations make them less desirable than constant velocity alternatives.

Conclusion – The Enduring Role of the Universal Joint

The universal joint has stood the test of time as a fundamental component in mechanical power transmission. From its 16th-century origins to modern automotive and industrial applications, the U-joint continues to deliver reliable performance in systems where flexibility and strength are paramount. While newer technologies like CV joints have taken over in certain roles, U-joints remain indispensable in trucks, heavy equipment, and machinery requiring high torque and angular adaptability.

Understanding how U-joints work, recognizing signs of failure, and performing regular maintenance are essential for ensuring the longevity and safety of any driveline system. As long as rotating machinery needs to operate under real-world conditions with misalignment and movement, the universal joint will remain a critical—and unsung—hero of mechanical engineering.

Frequently Asked Questions (FAQ)

What is the main purpose of a universal joint?

The primary purpose of a universal joint is to transmit rotational power between two shafts that are not aligned in a straight line, allowing for angular misalignment while maintaining torque transfer.

Can a bad U-joint damage my transmission or differential?

Yes, a failing U-joint can cause excessive vibration and shock loading, which may lead to premature wear or damage in the transmission, differential, or other drivetrain components.

How long do universal joints typically last?

On average, universal joints last around 100,000 miles, though lifespan varies based on driving conditions, maintenance, vehicle type, and joint quality.

Are all U-joints the same size and design?

No, U-joints come in various sizes, cross diameters, bearing cap widths, and designs tailored to specific applications and load requirements.

Can I drive a vehicle with a bad U-joint?

Driving with a damaged U-joint is not safe. Continued use can result in driveshaft failure, loss of control, or dangerous roadside breakdowns. Prompt inspection and repair are strongly advised.