U-joint Vs Ball Joint: Functionality & Failure Signs Compared

When it comes to vehicle maintenance, understanding the critical components that keep your car running smoothly is essential. Among these, U-joints (universal joints) and ball joints play pivotal roles in ensuring proper steering, suspension, and drivetrain functionality. While both are fundamental to vehicle performance, they serve distinct purposes and operate in different systems. This blog post dives into the functionality of U-joints and ball joints, explores their key differences, and highlights the signs of failure to help you identify and address issues before they escalate. By the end, you’ll have a clearer understanding of these components and why their maintenance is crucial for your vehicle’s safety and longevity.

Step-by-Step Process

Identify Components

Locate U-joints and ball joints in the drivetrain or suspension system.

Inspect for Wear

Check for excessive play, grease leaks, or corrosion on both joints.

Test Movement

Rotate U-joints and test ball joint articulation for smooth operation.

Listen for Noise

Identify clunks, squeaks, or grinding sounds during movement.

Replace if Necessary

Replace worn joints to prevent drivetrain or suspension failure.

Process infographic for U-joint Vs Ball Joint: Functionality & Failure Signs Compared

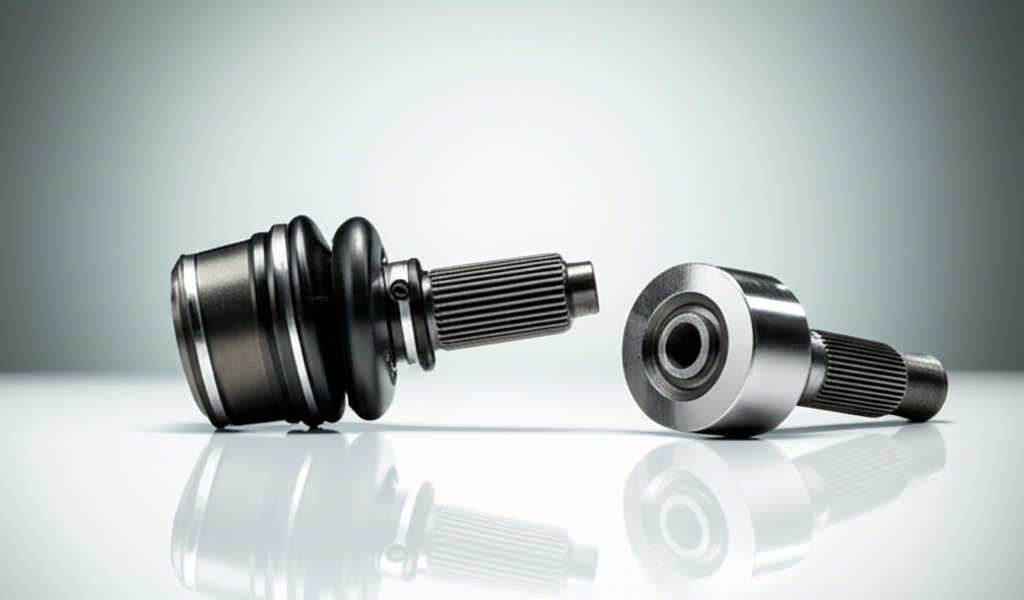

What is a U-Joint?

Definition and Purpose

A U-joint, short for universal joint, is a mechanical component that allows the transfer of torque between two shafts that are not in a straight line. It compensates for misalignment and enables smooth power transmission, even when the shafts are at an angle.

Common Applications

U-joints are commonly found in drivetrain systems, particularly in driveshafts and propeller shafts. They are essential in vehicles with rear-wheel or four-wheel drive, where the transmission and axle are not directly aligned.

Types of U-Joints

The most common types of U-joints include cross and roller joints, which are widely used in automotive applications, and double cardan joints, which are designed to reduce vibration and provide smoother operation.

What is a Ball Joint?

Definition and Purpose

A ball joint is a pivot point in the suspension system that connects the steering knuckle to the control arm. It allows for rotational and pivoting movement, enabling the wheels to turn and the suspension to absorb road irregularities.

Common Applications

Ball joints are integral to steering and suspension systems, typically found in the front suspension of vehicles. They connect components like the control arms and steering knuckles, ensuring smooth handling and stability.

Types of Ball Joints

Ball joints can be categorized as load-bearing or non-load-bearing. Load-bearing ball joints support the vehicle’s weight, while non-load-bearing joints primarily facilitate steering movement.

U-Joint vs Ball Joint: Key Differences

Primary Function

While U-joints are designed to transfer torque between misaligned shafts, ball joints facilitate movement in the suspension and steering systems, allowing for smooth turns and ride comfort.

Location in the Vehicle

U-joints are typically located in the drivetrain, such as the driveshaft, whereas ball joints are part of the suspension system, connecting the control arms and steering knuckles.

Design and Structure

U-joints consist of a cross-shaped mechanism with bearings, while ball joints feature a spherical bearing encased in a housing, allowing for multi-directional movement.

Signs of U-Joint Failure

Common Symptoms

Signs of a failing U-joint include clunking noises during gear changes, vibrations while driving, and difficulty shifting gears. These symptoms often worsen over time if not addressed.

Causes of Failure

U-joint failure can result from lack of lubrication, wear and tear, or corrosion. Exposure to dirt and moisture can also accelerate deterioration.

Impact on Vehicle Performance

A failed U-joint can lead to drivetrain damage, loss of power to the wheels, and even complete immobilization of the vehicle, posing significant safety risks.

Signs of Ball Joint Failure

Common Symptoms

Ball joint failure is often indicated by uneven tire wear, steering wander, and knocking sounds when driving over bumps. The vehicle may also feel unstable or pull to one side.

Causes of Failure

Common causes include dirt and debris ingress, rust, and excessive load. Over time, the constant stress on the joint can lead to wear and eventual failure.

Impact on Vehicle Performance

A failing ball joint compromises steering control and suspension stability, increasing the risk of accidents. In severe cases, it can cause the suspension to collapse.

Maintenance Tips for U-Joints and Ball Joints

Regular Inspection

Periodic checks for wear, damage, and play in these components are essential to catch issues early and prevent costly repairs.

Lubrication

Proper lubrication of U-joints and ball joints reduces friction and wear, extending their lifespan. Refer to your vehicle’s manual for recommended lubrication intervals.

Replacement Guidelines

Replace U-joints and ball joints at the first sign of failure or as recommended by your vehicle manufacturer. Delaying replacement can lead to more severe damage.

FAQ Section

What happens if a U-joint fails while driving?

A failed U-joint can cause loss of power to the wheels, drivetrain damage, and even immobilize the vehicle, making it unsafe to drive.

Can I drive with a bad ball joint?

Driving with a bad ball joint is dangerous, as it compromises steering control and can lead to suspension collapse. Immediate repair is necessary.

How often should U-joints and ball joints be inspected?

Inspect these components every 12,000 to 15,000 miles or as recommended by your vehicle’s maintenance schedule.

Are U-joints and ball joints expensive to replace?

Replacement costs vary depending on the vehicle and labor rates. While parts are relatively affordable, labor can increase the overall expense.

Can I replace a U-joint or ball joint myself?

While DIY replacement is possible for those with mechanical experience, it’s often best to seek professional help due to the complexity and safety risks involved.

Conclusion

U-joints and ball joints are indispensable components of your vehicle, each serving unique roles in the drivetrain and suspension systems. Understanding their functions, differences, and failure signs is key to maintaining your car’s performance and safety. Regular inspections, proper lubrication, and timely replacements can prevent costly repairs and ensure a smooth, safe driving experience. If you notice any signs of failure, consult a mechanic promptly to address the issue and keep your vehicle in top condition.