U Joint Strap Bolt Socket

When working on mechanical or automotive repairs, encountering stubborn bolts in tight spaces can be frustrating. That’s where U-joint strap bolt sockets come in—these specialized tools provide the flexibility and strength needed to tackle challenging fasteners. Whether you’re a DIY enthusiast or a professional mechanic, understanding the different types, applications, and selection criteria for U-joint strap bolt sockets can save you time and effort. This guide will walk you through everything you need to know, from identifying the right socket for your needs to using it safely and effectively.

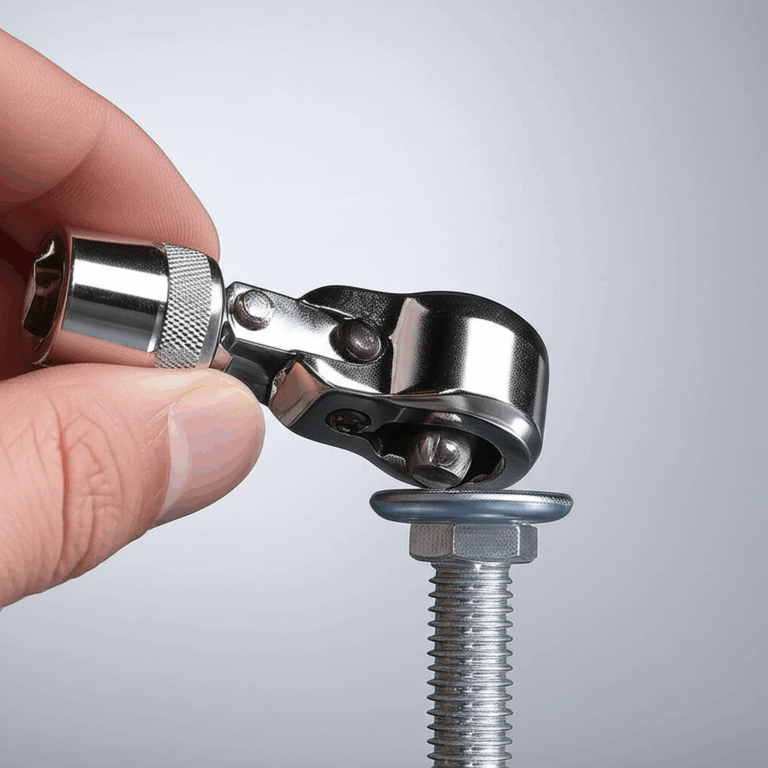

What is a U-Joint Strap Bolt Socket?

A U-joint strap bolt socket is a specialized tool designed to access bolts in confined or awkward spaces where standard sockets can’t reach. Unlike traditional sockets, these feature a universal joint (U-joint) mechanism that allows angular movement, making them ideal for hard-to-reach fasteners. They are commonly used in automotive repairs, industrial machinery, and farming equipment, where bolts are often located in tight or off-angle positions.

Types of U-Joint Strap Bolt Sockets

1. Standard U-Joint Sockets

Standard U-joint sockets are the most common type, featuring a basic design with a swivel joint that allows up to 25 degrees of movement. They are versatile and suitable for general repairs, maintenance, and routine bolt removal. These sockets are typically made from chrome vanadium steel for durability and corrosion resistance.

2. Impact-Resistant U-Joint Sockets

Designed for heavy-duty applications, impact-resistant U-joint sockets are reinforced with thicker walls and high-strength materials to withstand high torque and repeated use with impact tools. These are ideal for industrial settings, construction, or when dealing with rusted or seized bolts that require extra force.

3. Flexible U-Joint Sockets

Flexible U-joint sockets offer greater articulation, often up to 35 degrees, making them perfect for confined spaces like engine compartments or drivetrains. Their adjustable design allows mechanics to maneuver around obstructions while maintaining a secure fit on the bolt.

Key Features to Consider When Buying

1. Material Durability

The material of a U-joint socket significantly impacts its longevity. Chrome vanadium steel is a popular choice due to its balance of strength and corrosion resistance. For extreme conditions, look for forged alloy steel or impact-rated sockets, which offer superior durability.

2. Socket Size and Compatibility

Ensuring the socket matches the bolt size is critical. Always measure the bolt head diameter accurately and consult manufacturer size charts. Some sockets come in metric and SAE sizes, so verify compatibility with your application before purchasing.

3. Drive Size and Tool Compatibility

U-joint sockets are available in various drive sizes (1/2″, 3/8″, 1/4″), so choose one that fits your ratchet, breaker bar, or impact wrench. A mismatched drive size can lead to slippage or damage to both the tool and the bolt.

How to Use a U-Joint Strap Bolt Socket Properly

Step-by-Step Installation Guide

To use a U-joint socket effectively:

- Prep the work area by clearing debris and ensuring proper lighting.

- Align the socket with the bolt head, adjusting the angle as needed.

- Attach the socket to your tool and apply steady, controlled torque.

- Avoid excessive force to prevent stripping or damaging the bolt.

Safety Precautions

Always wear gloves and eye protection when working with U-joint sockets. Avoid over-tightening, as this can damage threads or break the socket. If a bolt is particularly stubborn, use penetrating oil to loosen it before applying force.

Common Problems and Troubleshooting

1. Socket Not Fitting Properly

If the socket doesn’t fit, double-check the bolt size and ensure the socket isn’t damaged. Applying anti-seize compound to the bolt head can also improve fitment and prevent future issues.

2. Socket Slipping or Stripping Bolts

Slippage often occurs due to excessive force or a worn socket. To prevent this, tighten gradually and use a breaker bar for better leverage. High-quality sockets with a secure grip are less likely to slip.

Top Brands and Where to Buy

Leading brands like Snap-on, Craftsman, and Husky offer reliable U-joint strap bolt sockets. You can find them at auto parts stores like AutoZone, online retailers such as Amazon, or through specialized tool suppliers.

FAQs About U-Joint Strap Bolt Sockets

Q1: Can I use a regular socket instead of a U-joint strap bolt socket?

A1: No, standard sockets lack the flexibility needed for tight angles. U-joint sockets are specifically designed for these scenarios.

Q2: How do I know the right size U-joint socket for my bolt?

A2: Measure the bolt head diameter and refer to the socket manufacturer’s size chart for accurate sizing.

Q3: Are impact-rated U-joint sockets worth the extra cost?

A3: Yes, if you frequently work with tough bolts, their durability justifies the investment.

Q4: Can I modify a U-joint socket for a different bolt size?

A4: Modifying sockets weakens them; it’s safer to purchase the correct size.

Q5: What’s the difference between a U-joint socket and a universal joint socket?

Comparison table for Q5: What’s the difference between a U-joint socket and a universal joint socket?

A5: Both are similar, but U-joint strap sockets are optimized for strap-style U-joints.

Conclusion

Choosing the right U-joint strap bolt socket can make a world of difference in efficiency and safety during repairs. By understanding the types, features, and proper usage, you can tackle even the toughest bolts with ease. Whether you’re a hobbyist or a professional, this guide should serve as a valuable resource for your next project. Always prioritize quality and safety to ensure long-lasting performance from your tools.