U Joint Socket Extension

Ever found yourself struggling to reach a stubborn bolt in a tight engine compartment or machinery frame? A U-joint socket extension could be your solution. This versatile tool bridges the gap between your ratchet or impact wrench and hard-to-reach fasteners, making automotive repairs and industrial maintenance much more efficient. Whether you’re a professional mechanic or a DIY enthusiast, understanding U-joint socket extensions is essential for tackling challenging tasks. In this guide, we’ll explore their functions, types, selection tips, and proper usage to help you work smarter, not harder.

Step-by-Step Process

Select the Right Tool

Choose a U-joint socket extension matching the drive size.

Attach the Extension

Thread the extension onto the ratchet handle securely.

Insert the Socket

Attach the U-joint socket to the extension's end.

Align with Fastener

Position the socket over the bolt or nut to be removed.

Apply Torque

Use the ratchet to apply force and loosen/tighten the fastener.

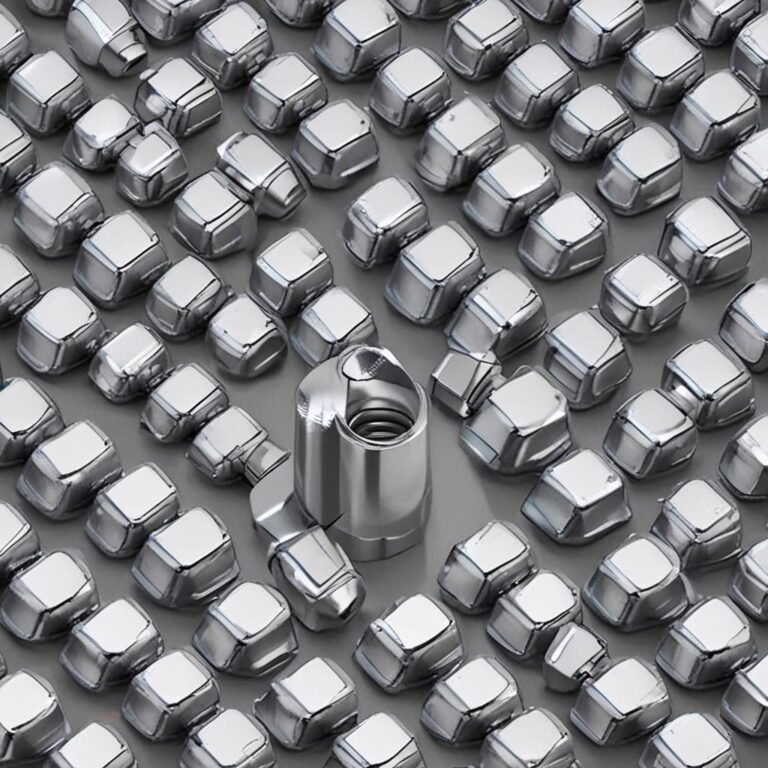

Process infographic for U Joint Socket Extension

What is a U-Joint Socket Extension?

A U-joint socket extension is a specialized tool that combines the flexibility of a universal joint with the reach of an extension bar. Unlike standard extensions, which only provide straight-line access, U-joint extensions allow for angular movement, making them ideal for navigating tight or awkward spaces. They’re commonly used in automotive repairs, machinery maintenance, and other applications where standard tools can’t reach.

Types of U-Joint Socket Extensions

By Design & Functionality

U-joint socket extensions come in different designs to suit various needs:

- Fixed-length extensions: Pre-set lengths for consistent reach and durability.

By Material & Construction

The material and build quality of a U-joint socket extension impact its performance and longevity:

- Steel extensions: Affordable and durable for general use.

When Do You Need a U-Joint Socket Extension?

A U-joint socket extension is invaluable in situations where standard tools fail to reach or maneuver effectively. Common scenarios include:

- Extended reach: Accessing fasteners deep inside machinery or engine compartments.

How to Choose the Right U-Joint Socket Extension

Key Factors to Consider

Selecting the right U-joint socket extension depends on several factors:

- Length: Measure the required reach and choose an extension that fits your workspace.

Brand & Quality Considerations

Investing in a reliable U-joint socket extension ensures long-term performance. Top brands like Snap-on, Craftsman, and GEARWRENCH offer trusted options, while budget-friendly choices from Harbor Freight or Husky work for occasional use. Read customer reviews to gauge durability and fit before purchasing.

How to Use a U-Joint Socket Extension Properly

Using a U-joint socket extension correctly maximizes efficiency and prevents damage:

- Attach the socket: Securely connect the socket to the extension by threading or slipping it on.

- Align the U-joint: Position the universal joint at the optimal angle to avoid binding.

- Apply force gradually: Start with light pressure to ensure proper engagement before increasing torque.

- Monitor wear: Inspect the U-joint for play or damage after prolonged use.

Common mistakes include over-tightening, misalignment, or using the wrong size extension—all of which can lead to tool failure or stripped bolts.

Maintenance & Care Tips

Proper care extends the lifespan of your U-joint socket extension:

- Cleaning: Wipe down the tool after use to remove grease, dirt, and debris.

Conclusion

A U-joint socket extension is a game-changer for anyone working in tight or hard-to-reach spaces. By understanding its types, selecting the right one for your needs, and maintaining it properly, you can tackle challenging tasks with ease. Whether you’re a professional mechanic or a DIY enthusiast, this tool is a valuable addition to your arsenal. Invest wisely, use it correctly, and enjoy smoother, more efficient repairs.

Frequently Asked Questions About U-Joint Socket Extensions

What is the difference between a U-joint socket extension and a standard extension?

Unlike standard extensions, which only provide straight-line access, U-joint extensions allow angular movement thanks to their universal joint design. This makes them ideal for navigating tight or awkward spaces.

Can I use a U-joint socket extension with any impact wrench or ratchet?

Yes, as long as the drive size matches (e.g., 1/4″, 3/8″, or 1/2″). Ensure the extension is rated for the torque of your impact wrench to avoid damage.

How do I know if my U-joint socket extension is worn out?

Check for excessive play in the U-joint, cracked threads, or difficulty rotating smoothly. If any of these issues arise, replace the extension.

Are universal U-joint socket extensions worth it, or should I buy specific ones?

Universal extensions offer flexibility but may not fit as snugly as tool-specific ones. For heavy-duty work, opt for extensions designed for your brand of sockets.

Can I modify a U-joint socket extension for a custom application?

While minor adjustments (like trimming length) are possible, avoid altering the U-joint mechanism, as this can compromise safety and performance.