U Joint Socket Adapter

A U-joint socket adapter is an essential tool for anyone working with nuts and bolts in tight or awkward spaces. By combining the flexibility of a universal joint with the precision of a socket, it allows for greater maneuverability when applying torque. From automotive repairs to industrial machinery maintenance, these adapters simplify tasks that would otherwise be frustrating or impossible. Whether you’re a seasoned mechanic or a weekend DIY enthusiast, understanding the capabilities and proper use of a U-joint socket adapter can significantly enhance your efficiency and effectiveness.

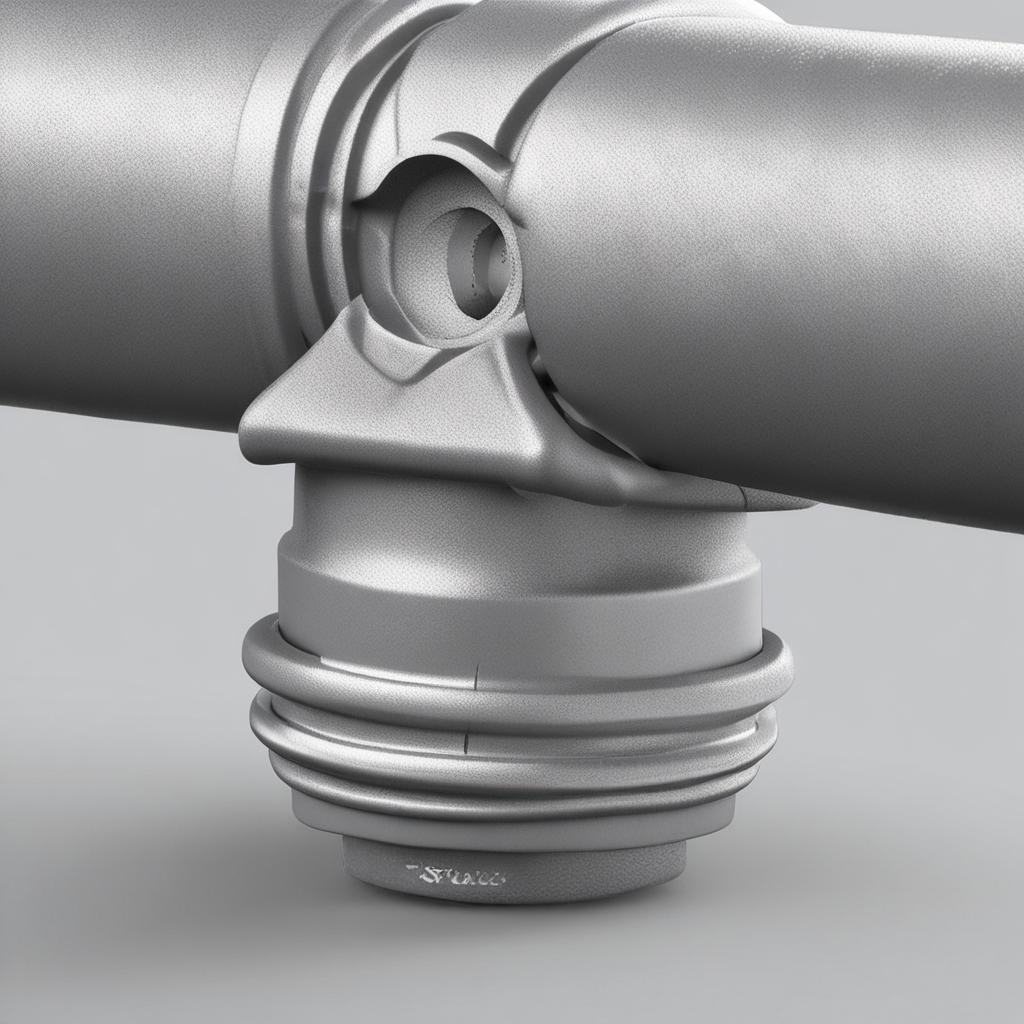

What is a U-Joint Socket Adapter?

Definition and Functionality

A U-joint socket adapter, also known as a universal joint adapter, is a tool designed to connect a socket to a ratchet or wrench in situations where a straight alignment isn’t possible. It features a flexible joint that allows movement in multiple planes, enabling the user to reach fasteners at odd angles. This adaptability makes it ideal for tasks where clearance is limited, such as working inside engine compartments or machinery with complex layouts.

Key Components

The adapter consists of a universal joint mechanism, typically made of interlocking balls or a cross-shaped design, and two socket attachment points: one for the drive end and another for the socket. The universal joint allows rotational movement, while the drive end connects to the ratchet or impact wrench. High-quality adapters often include a locking mechanism to secure the joint in place during use.

Common Uses

U-joint socket adapters are indispensable in automotive repair for accessing bolts in cramped engine areas. They’re also used in plumbing, HVAC systems, and industrial settings where angled or offset fasteners are prevalent. Their compact design and adaptability make them a go-to solution for overcoming spatial constraints.

Types of U-Joint Socket Adapters

Standard U-Joint Adapters

Standard adapters offer basic flexibility and are suitable for most general-purpose tasks. They are lightweight and affordable, making them a popular choice for non-impact applications like hand wrenching or low-torque jobs.

Locking U-Joint Adapters

Locking variants feature a mechanism that prevents the joint from moving during use, reducing the risk of slippage or misalignment. This added stability is particularly useful when applying significant force or working in vibration-heavy environments.

Swivel Head Adapters

Swivel head models provide even more flexibility by allowing the socket to rotate freely around the joint. This is helpful when the fastener is in a position that requires continuous motion adjustment, such as in deep recesses or around obstacles.

Material Variations

Adapters are made from materials like chrome vanadium steel for balance and rust resistance, or impact-grade steel for heavy-duty use with power tools. The material choice affects durability, load capacity, and suitability for specific applications.

How to Choose the Right U-Joint Socket Adapter

Socket Size Compatibility

Ensure the adapter matches your socket set’s drive size (commonly 3/8″, 1/2″, or 3/4″). Check if the socket attachment points are standardized, as some models may require specific interfaces.

Essential Checklist

Goal Definition

Clearly define objectives and success metrics

Resource Planning

Allocate necessary time, budget, and personnel

Implementation Strategy

Develop step-by-step execution plan

Quality Assurance

Establish testing and validation procedures

Performance Monitoring

Set up tracking and reporting systems

Essential items for U Joint Socket Adapter

Torque Requirements

For high-torque tasks, opt for impact-rated adapters. Non-impact versions may bend or break under stress. Always verify the adapter’s torque rating against the demands of your project.

Durability and Quality

Invest in adapters from reputable brands known for precision engineering. Look for reinforced joints, rust-resistant coatings, and a sturdy build to ensure longevity, especially in professional settings.

Application-Specific Needs

Automotive work often requires compact, lightweight adapters, while industrial applications may prioritize rugged, impact-resistant designs. Consider the environment and frequency of use when making your selection.

How to Use a U-Joint Socket Adapter Safely and Effectively

Step-by-Step Guide

- Attach the adapter to your ratchet or wrench using a compatible socket.

Safety Tips

Never force the adapter if it doesn’t align properly, as this can damage the joint or fastener. Use the correct socket size to prevent slippage, and avoid using non-impact adapters with power tools to prevent breakage.

Maintenance and Care

Clean the adapter after each use to remove debris, lubricate moving parts periodically, and store it in a dry place. Inspect for cracks or wear to ensure it remains safe and functional over time.

Advantages of Using a U-Joint Socket Adapter

Increased Flexibility

The universal joint design allows you to work around obstructions and reach fasteners in tight spaces, eliminating the need for disassembly in many cases.

Versatility

These adapters work with a wide range of socket sizes and tools, making them a multipurpose addition to any toolkit. They are compatible with both standard and metric fasteners.

Time and Effort Savings

By enabling access to hard-to-reach areas, U-joint adapters reduce the time spent on disassembly and reassembly, allowing for quicker and more efficient repairs.

Common Issues and Troubleshooting

Wobbling or Slipping

Causes include incorrect socket size or a worn universal joint. Solutions involve using a locking adapter, ensuring proper fit, or replacing damaged components.

Wear and Tear

Signs of wear include reduced flexibility, visible cracks, or a loose joint. Replace the adapter if these issues arise to maintain tool integrity and prevent accidents.

Misalignment Problems

Improper alignment can strip fasteners or damage the tool. Use the adapter in a neutral position as much as possible and avoid excessive angles during high-torque applications.

Top Brands and Products

Leading brands like Craftsman, Stanley, and Snap-on offer durable, high-performance U-joint socket adapters. Look for models with reinforced joints and clear drive size markings. Prices vary from budget-friendly options to premium sets, with impact-rated versions typically costing more. Consider your specific needs and usage frequency when evaluating value for money.

Conclusion

U-joint socket adapters are a game-changer for professionals and hobbyists alike, offering unmatched flexibility and versatility in challenging environments. By choosing the right adapter for your tasks and following proper usage guidelines, you can streamline your work and avoid unnecessary frustration. Add a reliable U-joint socket adapter to your toolkit today, and explore other specialized tools to further enhance your efficiency.

FAQ Section

What is the difference between a U-joint socket adapter and a swivel socket?

A U-joint adapter uses a universal joint for multi-directional movement, while a swivel socket allows 360-degree rotation in a single plane. U-joint adapters are better for complex angles, whereas swivel sockets suit shallow, linear access points.

Can I use a U-joint socket adapter with an impact wrench?

Only if the adapter is specifically rated for impact use. Standard adapters lack the durability to withstand high-torque vibrations and may fail, causing injury or damage. Check the manufacturer’s specifications before use.

How do I prevent a U-joint socket adapter from slipping?

Use the correct socket size, ensure the joint is locked if applicable, and apply even pressure. Regularly inspect the adapter for wear, and replace it if the joint no longer holds securely.

What sizes do U-joint socket adapters come in?

They are available in 3/8″, 1/2″, and 3/4″ drive sizes. Socket attachment points may vary by brand, so confirm compatibility with your existing tools before purchasing.

Are U-joint socket adapters universal?

Most adapters are designed to fit standard sockets, but always verify the drive size and interface type. Some specialized models may require specific socket designs for secure attachment.