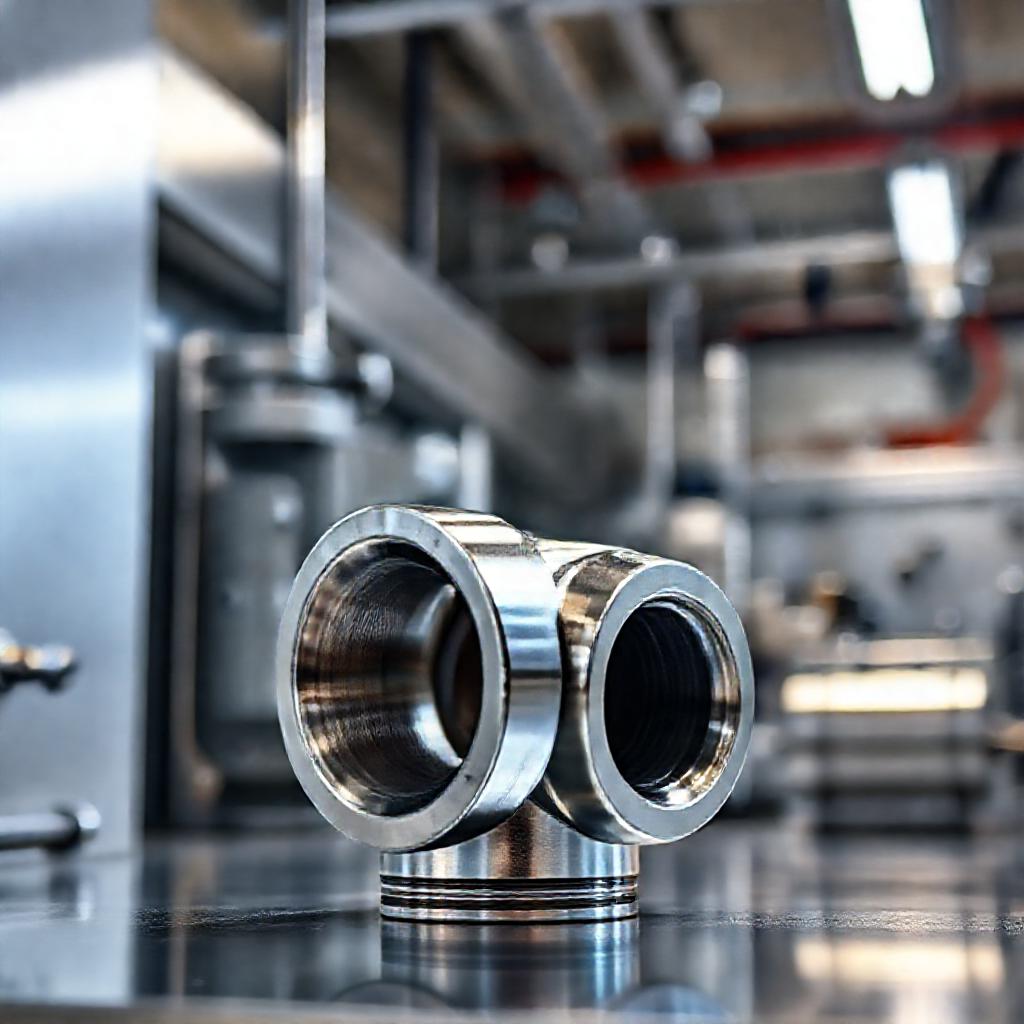

Swivel Universal Joint Socket

When it comes to precision engineering and mechanical applications, the swivel universal joint socket plays a crucial role in ensuring smooth and efficient operation. This versatile component is designed to transmit rotational motion between two shafts that are not in a straight line, making it indispensable in a wide range of industries, from automotive to industrial machinery. Understanding its function, design, and applications can help you appreciate its importance and make informed decisions when selecting or maintaining these components.

What is a Swivel Universal Joint Socket?

A swivel universal joint socket, often referred to as a U-joint or universal joint, is a mechanical device that allows for the transmission of rotary mechanical power between two shafts that are not collinear. This joint is designed to accommodate angular misalignment and can operate under various angles, making it highly versatile. The swivel action of the joint ensures that the rotational motion is transferred smoothly and efficiently, even when the shafts are not perfectly aligned.

Design and Function

Components of a Swivel Universal Joint Socket

The swivel universal joint socket consists of several key components:

- Yokes: These are the fork-shaped parts that connect the joint to the shafts.

How It Works

The swivel universal joint socket operates by allowing the cross to pivot and rotate within the yokes. This movement accommodates the angular misalignment between the two shafts. As the shafts rotate, the cross and bearings ensure that the motion is transferred smoothly, even when the shafts are at different angles. This design makes the joint highly effective in applications where precise and reliable transmission of power is crucial.

Applications of Swivel Universal Joint Sockets

Automotive Industry

In the automotive industry, swivel universal joint sockets are commonly used in drive shafts to connect the transmission to the wheels. They are essential in transmitting power from the engine to the wheels, especially in vehicles with rear-wheel drive. The ability of the U-joint to handle angular misalignment ensures that the power is transferred efficiently, even when the wheels move up and down over bumps.

Industrial Machinery

Swivel universal joint sockets are also widely used in industrial machinery, such as conveyor systems, mixers, and pumps. In these applications, the joint helps to transmit power from motors to various moving parts, ensuring smooth and consistent operation. The versatility of the U-joint makes it suitable for a wide range of industrial environments, from factories to construction sites.

Agricultural Equipment

Farm equipment, such as tractors and harvesters, often rely on swivel universal joint sockets to transmit power to different parts of the machinery. The joint’s ability to handle angular misalignment is particularly useful in agricultural settings, where the terrain can be uneven and the equipment needs to operate reliably under various conditions.

Maintenance and Care

To ensure the longevity and optimal performance of swivel universal joint sockets, regular maintenance is essential. Here are some key maintenance tips:

- Lubrication: Regularly lubricate the joint to reduce friction and prevent wear. Use a high-quality lubricant recommended by the manufacturer.

Conclusion

The swivel universal joint socket is a critical component in many mechanical systems, ensuring the smooth and efficient transmission of rotational power. Its ability to handle angular misalignment makes it indispensable in various industries, from automotive to industrial machinery and agriculture. By understanding its design, function, and applications, you can better appreciate its importance and ensure that it performs reliably in your equipment. Regular maintenance and care are essential to prolong its lifespan and maintain optimal performance.