Socket weld fittings are a cornerstone of modern piping systems, offering durability and reliability in high-pressure and high-temperature environments. These fittings are widely used across industries like oil and gas, chemical processing, and petrochemicals. However, designing and implementing a piping system requires precision, especially when it comes to material estimation and procurement. This is where a socket weld take-off chart becomes invaluable. By providing detailed information on fitting types, sizes, and quantities, these charts ensure accuracy, efficiency, and cost savings throughout the project lifecycle. Whether you’re a seasoned engineer or a project manager, understanding how to use a socket weld take-off chart can significantly streamline your workflow and enhance the integrity of your piping systems.

Understanding Socket Weld Fittings

What Are Socket Weld Fittings?

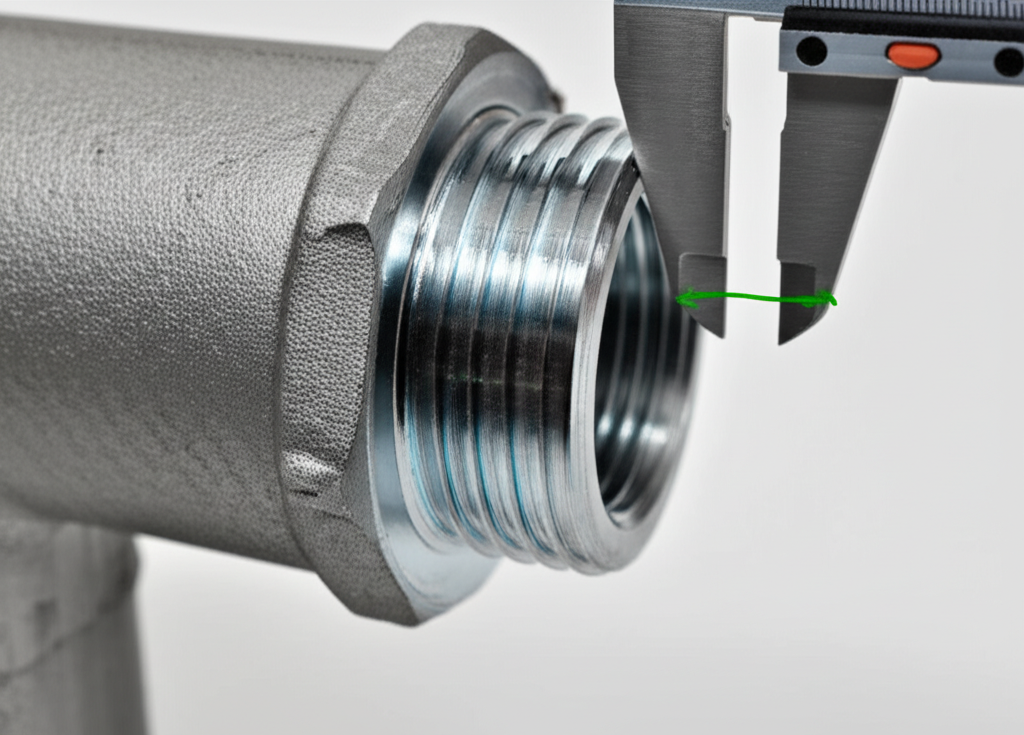

Socket weld fittings are pipe fittings designed to connect pipes by inserting them into a recessed area and then welding around the joint. This creates a strong, leak-proof connection ideal for small-diameter piping systems. Common types of socket weld fittings include elbows, tees, couplings, and reducers. Unlike butt weld fittings, which require the pipe ends to be welded together directly, socket weld fittings are easier to install and provide better alignment during assembly.

Applications of Socket Weld Fittings

Socket weld fittings are predominantly used in industries where high-pressure and high-temperature conditions are prevalent. They are commonly found in oil and gas pipelines, chemical plants, and petrochemical facilities. Their robust design makes them suitable for handling hazardous fluids and gases. Materials like carbon steel, stainless steel, and various alloys are often used to manufacture these fittings, ensuring they can withstand harsh operating conditions.

What Is a Socket Weld Take-Off Chart?

Definition and Purpose

A socket weld take-off chart is a detailed document used in piping design to estimate the types, sizes, and quantities of fittings required for a project. It serves as a blueprint for material procurement, helping engineers and project managers plan effectively. By using a take-off chart, teams can avoid over-purchasing or underestimating materials, which can lead to cost overruns or delays.

Components of a Socket Weld Take-Off Chart

A typical socket weld take-off chart includes key elements such as fitting sizes, quantities, dimensions, and material specifications. Standard symbols and abbreviations are used to represent different fitting types and sizes, ensuring clarity and consistency. Additionally, these charts adhere to industry standards like ASME, ANSI, and ASTM, which guarantee the reliability and safety of the fittings.

How to Use a Socket Weld Take-Off Chart

Step-by-Step Guide to Reading a Take-Off Chart

Begin by identifying the types of fittings required for your piping system, such as elbows, tees, or reducers. Next, determine the sizes and quantities based on the piping layout and project specifications. Cross-reference these details with the take-off chart to ensure accuracy. This process helps streamline material procurement and reduces the risk of errors during installation.

Common Mistakes to Avoid

One of the most common mistakes is selecting the wrong fitting type or size, which can lead to leaks or system failures. Misinterpreting dimensions and tolerances can also cause compatibility issues. Additionally, overlooking material compatibility can result in corrosion or premature wear. Always double-check the chart and consult with experts to avoid these pitfalls.

Benefits of Using a Socket Weld Take-Off Chart

Accuracy in Material Estimation

Using a socket weld take-off chart ensures precise material estimation, reducing waste and excess inventory. This accuracy also guarantees that the correct fittings are selected, leading to seamless installation and optimal performance.

Cost and Time Savings

Take-off charts streamline the procurement process, minimizing delays and reducing the need for rework. By avoiding incorrect material selection, projects can stay on schedule and within budget.

Compliance with Industry Standards

Adhering to standardized take-off charts ensures compliance with safety and quality regulations. This not only enhances the reliability of the piping system but also reduces the risk of costly failures.

Socket Weld Take-Off Chart Examples

Sample Charts for Different Fitting Types

Take-off charts are available for various fitting types, including 90° and 45° elbows, equal and reducing tees, and couplings. These charts provide detailed information on dimensions, quantities, and material specifications, making it easy to select the right components for your project.

How to Customize a Take-Off Chart for Your Project

For unique piping configurations, you can customize a take-off chart to include special material requirements or non-standard fitting sizes. This flexibility ensures that the chart meets the specific needs of your project.

Conclusion

Socket weld take-off charts are indispensable tools in the design and implementation of piping systems. They enhance accuracy, streamline procurement, and ensure compliance with industry standards. By following best practices and using standardized charts, you can achieve efficient and reliable piping installations. Embrace the power of socket weld take-off charts to elevate your project planning and execution.

FAQs About Socket Weld Take-Off Charts

What is the difference between a socket weld and a butt weld fitting?

Comparison table for What is the difference between a socket weld and a butt weld fitting?

Socket weld fittings involve inserting the pipe into a recessed area and welding around the joint, while butt weld fittings require welding the pipe ends directly together. Socket weld fittings are easier to align and install, making them ideal for small-diameter pipes.

How do I ensure accuracy when using a socket weld take-off chart?

Double-check the dimensions, quantities, and material specifications listed in the chart. Cross-reference these details with your project requirements and consult with experts if needed.

Can I use a take-off chart for both carbon and stainless steel fittings?

Yes, take-off charts are available for various materials, including carbon steel and stainless steel. Ensure the chart you use specifies the material type to avoid compatibility issues.

Where can I find pre-made socket weld take-off charts?

Pre-made charts are available on manufacturer websites, industry databases, and engineering resources. These charts are often tailored to meet specific standards and requirements.

What are the consequences of using the wrong fitting in a socket weld system?

Using the wrong fitting can lead to leaks, corrosion, and system failures. It can also result in costly repairs and downtime, making accurate material selection critical.