Socket Size Order Chart

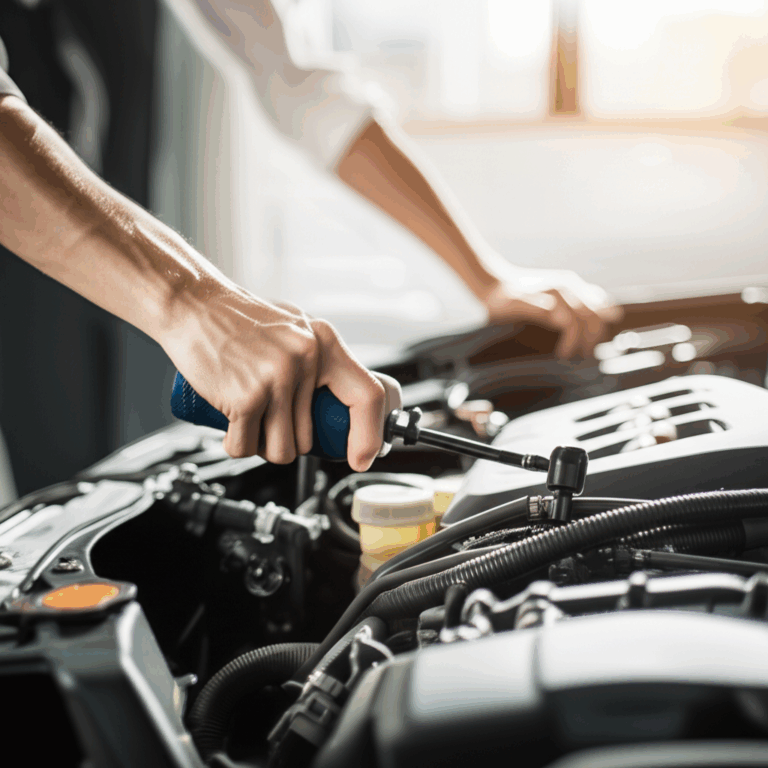

Whether you’re a seasoned mechanic, a DIY enthusiast, or a professional in the automotive or construction industry, having the right socket size is crucial for every project. The wrong socket can strip bolts, damage tools, or even pose safety risks. That’s where a socket size order chart comes in handy. This handy reference organizes socket sizes, making it easier to identify the perfect fit for any job. In this guide, we’ll explore the importance of socket sizes, how to use a socket size order chart, and tips for choosing the right socket set for your needs.

Understanding Socket Sizes

What Are Socket Sizes?

Socket sizes refer to the diameter of the opening in a socket wrench that fits around a bolt or nut. They are essential for tightening or loosening fasteners efficiently. Sockets come in two primary measurement systems: metric (millimeters) and imperial (Society of Automotive Engineers, or SAE, in inches). Understanding both systems is important, especially since different regions and industries may use one over the other.

Importance of Using the Correct Socket Size

Using the right socket size ensures a snug fit, preventing slippage that can damage the bolt or nut. A properly sized socket distributes force evenly, reducing the risk of rounding off edges or stripping threads. Safety is another key factor—an incorrect socket can slip, causing injury or tool damage. Always double-check the size before applying torque to avoid mishaps.

Socket Size Order Chart Explained

What Is a Socket Size Order Chart?

A socket size order chart is a reference tool that lists socket sizes in ascending or descending order, making it easier to locate the correct size quickly. These charts can be found in print, digital formats, or even included in toolkits. They are invaluable for professionals and hobbyists who need to organize and access the right socket without guesswork.

Metric Socket Size Order Chart

Metric sockets are measured in millimeters (mm) and are commonly used in modern vehicles, machinery, and construction. Here’s a typical range of metric socket sizes:

- 6mm, 7mm, 8mm, 9mm, 10mm

These sizes are frequently used in automotive work, bicycle maintenance, and industrial applications.

Imperial (SAE) Socket Size Order Chart

SAE sockets are measured in fractions of an inch and are prevalent in older vehicles, machinery, and some construction tools. Common SAE socket sizes include:

- 1/4″, 5/16″, 11/32″, 3/8″

These sizes are often used in older car models and certain machinery where imperial measurements are standard.

Specialty Socket Sizes

Beyond standard hex sockets, specialty sockets like Torx (star-shaped) and Allen (hex key) are designed for specific fasteners. Torx sockets are common in newer vehicles and electronics, while Allen sockets are used in furniture assembly and some machinery. Always check the fastener type before selecting a socket to ensure compatibility.

How to Use a Socket Size Order Chart

Step-by-Step Guide

Using a socket size order chart is straightforward:

- Identify the Bolt or Nut: Measure the fastener’s width across the flats (for hex bolts) or consult a specifications chart.

Tips for Organizing Sockets

Keeping sockets organized saves time and prevents frustration. Consider these tips:

- Toolbox Arrangement: Use a racked toolbox or drawer inserts to separate sockets by size and type.

Choosing the Right Socket Set

Factors to Consider

When selecting a socket set, consider:

- Size Range: Ensure the set covers the sizes you need most, from small fasteners to large bolts.

Popular Socket Set Brands

Reputable brands like Snap-on, Craftsman, and Mac Tools offer high-quality socket sets with excellent durability. For budget-friendly options, consider DeWalt or GEARWRENCH, which balance affordability and performance.

Conclusion

A socket size order chart is an invaluable resource for anyone working with fasteners. It simplifies the process of selecting the right socket, ensuring efficiency, safety, and tool longevity. Whether you’re tackling a home repair or a professional project, investing in a reliable socket set and using the chart will save you time and frustration. Always double-check your measurements and socket compatibility to avoid costly mistakes.

FAQ Section

1. What is the difference between metric and SAE socket sizes?

Comparison table for 1. What is the difference between metric and SAE socket sizes?

Metric sockets are measured in millimeters (mm) and are standard in most modern applications, while SAE sockets are measured in fractions of an inch and are common in older equipment. The two systems are not interchangeable, so always verify the measurement system required for your project.

2. How do I know which socket size to use?

Measure the width across the flats of the bolt or nut and match it to the socket size chart. For example, a 10mm bolt typically needs a 10mm socket. If unsure, start with a slightly smaller size and work your way up to avoid stripping the bolt.

3. Can I use a metric socket on an SAE bolt?

Using a metric socket on an SAE bolt is not recommended. The slight size difference can cause slippage, damage to the fastener, or tool breakage. Always use the correct measurement system for compatibility.

4. What are the most commonly used socket sizes?

For metric sockets, sizes like 10mm, 12mm, 13mm, 14mm, and 17mm are frequently used. Common SAE sizes include 3/8″, 1/2″, 9/16″, and 5/8″. These sizes cover a wide range of applications in automotive and general repair work.

5. Where can I find a printable socket size order chart?

Many tool manufacturers, such as Craftsman and Snap-on, offer downloadable socket size charts on their websites. You can also find printable versions through automotive forums or tool supply retailers.