Socket Head Cap Screw Size Chart

Socket head cap screws are essential components in countless engineering and manufacturing applications, prized for their robust design and precision. These screws feature a cylindrical head with a hexagonal socket, allowing for high torque application and a low-profile fit in tight spaces. Commonly made from materials like stainless steel, alloy steel, or titanium, they are used in machinery, automotive assembly, and aerospace projects where strength, durability, and space efficiency are critical. However, selecting the correct socket head cap screw size is vital to ensure optimal performance and safety. This blog post will break down socket head cap screw size charts, explain key measurements, and provide actionable tips for choosing the right fasteners for your project.

Understanding Socket Head Cap Screws

What Are Socket Head Cap Screws?

Socket head cap screws (SHCS) are a type of fastener designed for high-strength applications. Their cylindrical heads and internal hex sockets make them ideal for use with Allen wrenches or hex drivers. Unlike flat head screws, which sit flush with the surface, or pan head screws, which have a rounded top, SHCS offer a compact, sturdy solution that resists stripping under high torque. They are often manufactured to standards like ISO 4762 and ASME B18.3, ensuring consistency in dimensions and performance.

Common Applications and Industries

Industries such as robotics, construction, and heavy machinery rely on socket head cap screws for their reliability. They are frequently used in scenarios requiring resistance to vibration and high tension, such as securing engine components or assembling robotic arms. In these cases, precise sizing is crucial to prevent mechanical failure or over-tightening, which can damage materials or components.

Standard Types and Specifications

SHCS are available in metric (M4, M5, M6) and imperial (1/4″, 5/16″, 3/8″) sizes, with thread pitches and drive diameters varying accordingly. Key specifications include the screw’s diameter, length, thread type (coarse or fine), and head height. These parameters determine compatibility with nuts, threaded holes, and tools, making it essential to reference a size chart for accuracy.

Decoding the Socket Head Cap Screw Size Chart

Key Parameters in Size Charts

Diameter (Major/Minor Thread)

Socket head cap screw size charts list diameters in both metric and imperial units. The metric system uses terms like M4 (4mm thread diameter), while imperial sizes are expressed as fractions of an inch (e.g., 1/4″). To measure diameter, use calipers to determine the distance across the threaded part. Charts often provide equivalents, such as M6 ≈ 1/4″, but these are approximate due to differences in thread profiles.

Length Measurements

Length specifications refer to the distance from the underside of the head to the tip of the screw. Charts may list lengths in millimeters or inches, with standard increments like 8mm, 10mm, or 1/2″. Always confirm whether the measurement includes the head or is head-to-tip, as this can impact how the screw fits in your assembly.

Thread Pitch and Series

Imperial threads use UNC (coarse), UNF (fine), and UNEF (extra fine) classifications, while metric threads are defined by numerical values like 1.0mm or 1.5mm. Coarse threads are suited for softer materials or quick assembly, whereas fine threads provide better load distribution and are ideal for precision tasks. Understanding these differences helps avoid stripping or improper engagement.

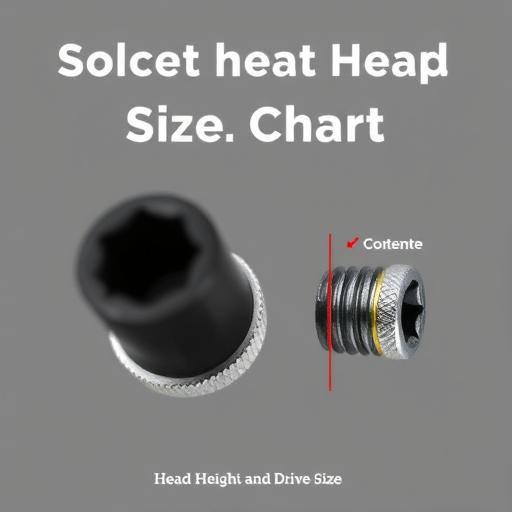

Head Height and Drive Size

Head height is typically proportional to the screw’s diameter, with a common ratio of 0.8d for 90° head angles. The drive size, such as 1/4″ for M5 screws, ensures compatibility with sockets or Allen wrenches. Charts will specify these dimensions to help you avoid installation issues like stripped drives or insufficient clearance.

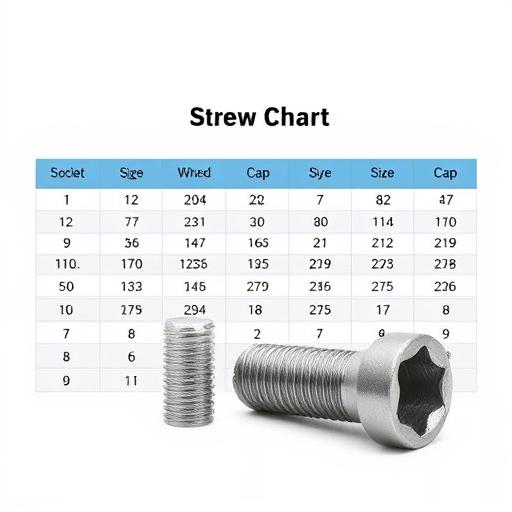

Reading and Interpreting the Chart

To use a socket head cap screw size chart, cross-reference the diameter, length, and thread pitch to identify the correct part number. For example, a metric M6 screw with a 1.0mm pitch and 15mm length will have a unique code for ordering. Visual examples in charts often include tables comparing imperial and metric equivalents, while annotations may highlight tolerances and strength grades. Always verify the material marking (e.g., A2 for stainless steel) to ensure it matches your project’s needs.

How to Use a Socket Head Cap Screw Size Chart

Identify Your Project Requirements

Begin by assessing the load the screw must bear, the space available for installation, and environmental factors like moisture or temperature. These considerations will guide your selection of diameter, thread type, and material.

Select the Appropriate Diameter

Match the screw’s diameter to the size of the threaded hole or nut. For instance, an M5 screw is generally equivalent to 5/32″ in imperial, but always double-check compatibility. Mixing metric and imperial units can lead to costly errors.

Choose the Right Thread Pitch

Coarse threads (UNC/UNF) are recommended for rough materials like wood or plastic, while fine threads (UNEF or metric pitches) are better suited for metal and high-tolerance applications. A size chart will simplify this decision by listing recommended pitches for each diameter.

Determine the Correct Length

Calculate the required length by measuring the thickness of the materials being joined and adding the depth needed to engage with the thread. For example, a 10mm material might require a 12mm screw to allow for proper clamping and nut placement.

Verify Head Height and Drive Compatibility

Check that the head height won’t interfere with surrounding components and that the drive size (e.g., 5/32″, 3/16″) matches your tools. A mismatch here can result in stripped threads or incomplete tightening.

Common Mistakes to Avoid

- Mixing metric and imperial units without proper conversion.

Practical Considerations for Sizing

Load-Bearing and Torque Requirements

Larger diameters and finer threads increase load capacity and torque resistance. Refer to the chart’s strength grade (e.g., 8.8 for metric, Grade 5 for imperial) to ensure the screw can handle the stress of your application.

Temperature and Environmental Factors

Material selection is tied to size and environment. Stainless steel offers corrosion resistance for outdoor or marine use, while titanium is preferred for high-heat scenarios. The size chart should include material-specific guidelines to help you choose wisely.

Custom vs. Standard Sizes

Comparison table for Custom vs. Standard Sizes

While standard sizes cover most applications, non-standard lengths or diameters may be necessary for unique designs. When this occurs, consult with suppliers who can source or manufacture custom SHCS to exact specifications.

FAQ: Socket Head Cap Screw Size Chart

What Are the Most Common Socket Head Cap Screw Sizes?

Popular metric sizes include M4, M5, and M6, while imperial equivalents like 1/4″, 5/16″, and 3/8″ are widely used. M4 and 1/4″ screws are ideal for light-duty applications, whereas M8 and 5/16″ are suited for heavier loads. For a deeper dive into socket head screw applications, explore industry-specific use cases.

How Do I Choose Between Coarse and Fine Thread Screws?

Coarse threads are better for quick assembly and softer materials, while fine threads provide greater strength and stability. If your project requires precision or is subject to high vibration, fine-threaded screws are typically the safer choice.

Can I Convert Metric Sizes to Imperial Units and Vice Versa?

Yes, but note that conversions like M6 ≈ 1/4″ are approximate. Always cross-reference with a metric socket head cap screw dimensions chart to account for differences in thread pitch and major diameters.

Why Is Head Height Important in Socket Head Screws?

Head height affects how much mechanical stress the screw can withstand and whether it fits in confined spaces. A taller head may offer more strength but could obstruct adjacent components. For more on this, see head height and drive size compatibility guidelines.

Where Can I Find a Reliable Socket Head Cap Screw Size Chart?

Manufacturer websites, engineering resources, and standards like ISO and ASME provide accurate size charts. Always verify the chart includes tolerances, strength grades, and material specifications relevant to your project.

Conclusion

Properly sizing socket head cap screws is crucial for the integrity and longevity of any mechanical system. By understanding the parameters outlined in this guide and using a detailed size chart, you can make informed decisions that enhance safety and performance. For complex projects or when working with mixed unit systems, consult a professional or reach out to a trusted supplier. Comprehensive charts and online tools are readily available to simplify this process, ensuring your fasteners meet exact specifications every time.