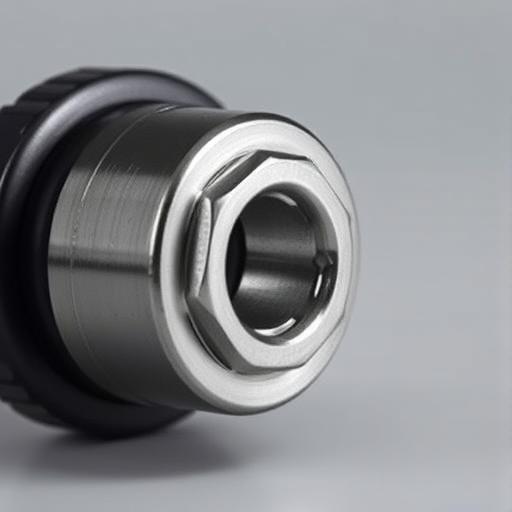

Socket and Universal Joint Combined

When tackling complex mechanical tasks, having the right tools can make all the difference. Sockets and universal joints, though distinct in their functions, become a powerful duo when combined. Sockets provide the leverage needed to tighten or loosen fasteners, while universal joints (U-joints) allow for angular movement between shafts. Together, they enable torque transmission in challenging environments where alignment is imperfect. This synergy is vital in industries like automotive, industrial machinery, and HVAC systems, where flexibility and precision are paramount. In this post, we’ll explore how these components work in unison, their practical applications, and why they’re indispensable for both professionals and DIY enthusiasts.

Understanding the Basics of Sockets and Universal Joints

What is a Socket?

A socket is a tool used with a ratchet, wrench, or power drill to apply or remove torque from nuts and bolts. Sockets come in various types, including SAE (standard) and metric sizes, as well as deep-wall and standard designs. Deep-wall sockets are ideal for recessed fasteners, while standard sockets work for typical applications. Their primary role is to securely engage fasteners, ensuring efficient force transfer without slippage.

What is a Universal Joint?

A universal joint, or U-joint, is a mechanical coupling that allows the transmission of rotational motion between two non-aligned shafts. It consists of a cross-shaped yoke and bearings, which accommodate angular misalignment and torsional flexibility. U-joints are commonly found in automotive drive shafts, industrial robotics, and heavy machinery. Their ability to adapt to dynamic movements makes them essential for systems where rigid connections are impractical.

The Mechanics of Combining Sockets and Universal Joints

How Do Sockets and Universal Joints Work Together?

Combining a socket with a U-joint creates a flexible torque transmission system. The U-joint allows the socket to pivot at an angle, enabling access to fasteners in tight or awkward spaces. This setup compensates for angular misalignment by distributing rotational forces evenly through the joint’s bearings and yoke. However, maintaining proper alignment and staying within angular limits is crucial to prevent mechanical strain and failure.

Common Configurations and Designs

Flexible socket extensions and U-joint-driven torque tools are typical configurations. These tools often use materials like hardened steel or chrome vanadium for durability, ensuring they handle high loads and resist wear. Advanced designs may include sealed bearings and corrosion-resistant coatings to perform reliably in harsh environments.

Applications in Industry and Automotive Fields

In automotive drivelines, socket-U-joint combinations simplify the installation and repair of components like drive shafts and CV axles. Industrial machinery benefits from these tools in robotics and conveyor systems, where torque must be applied in confined or multi-axis setups. HVAC technicians use them to navigate around obstacles such as ductwork, ensuring efficient plumbing or ventilation repairs.

Benefits of Using a Socket and Universal Joint Combination

Features table for Benefits of Using a Socket and Universal Joint Combination

Flexibility in Tight or Inaccessible Spaces

The angular movement provided by the U-joint allows sockets to reach fasteners blocked by obstructions. Unlike rigid tools, this combination adapts to irregular angles, making it invaluable for complex assemblies. For example, mechanics can use it to tighten bolts in the cramped spaces of a vehicle’s undercarriage.

Reduced Wear and Tear on Equipment

By accommodating misalignment, the U-joint reduces stress on both the socket and connected machinery. This minimizes component fatigue, extending tool life and lowering replacement costs. In industrial settings, this wear resistance translates to fewer downtime incidents and consistent performance.

Enhanced Torque Transmission Efficiency

The socket-U-joint system ensures smooth power transfer while dampening vibrations caused by angular shifts. This efficiency is critical in high-torque applications, such as assembling heavy machinery or repairing drivetrains. The design prevents backlash, maintaining precision even under demanding loads.

Selecting the Right Socket and Universal Joint Combination

Key Factors to Consider

- Torque requirements: Match socket size and U-joint load ratings to avoid overworking components.

Compatibility with Tools and Equipment

Ensure the socket fits standard ratchets or power tools and that the U-joint aligns with shaft dimensions. Adapters or specialized kits can bridge compatibility gaps, such as connecting a U-joint to a power drill. Always verify specifications before assembly.

Case Scenarios for Optimal Choice

High-torque tasks, like engine repairs, demand robust sockets and heavy-duty U-joints. Conversely, low-torque applications, such as electronics assembly, require lighter, more precise tools. For angular motion needs, a U-joint combination is preferable over linear tools in offset scenarios.

Maintenance and Troubleshooting Tips

Regular Inspection and Lubrication

Periodically check U-joint bearings for wear and socket edges for deformation. Greasing the joint’s moving parts every few months prevents friction-related damage. In wet or corrosive environments, use waterproof lubricants to avoid rust.

Common Issues and Solutions

Misalignment Problems

Symptoms include resistance, unusual noises, or vibration during use. Adjust the U-joint’s angle or replace worn bearings to resolve these issues. In severe cases, recalibrate the entire system for proper alignment.

Socket Slippage

Slippage occurs when the socket doesn’t grip the fastener. Use anti-slip coated sockets or check for wear. Avoid overloading the tool beyond its rated torque capacity to ensure a secure fit.

When to Replace the Combination

Replace the assembly if the U-joint shows play or the socket becomes stripped. Cracks in the yoke or excessive corrosion are red flags. Regular maintenance can delay replacements, but safety and performance must always take priority.

Case Study: Real-World Application of Socket and Universal Joint Combinations

Automotive repair shops often use U-joint socket tools for CV axle assembly, where limited access makes direct tightening impossible. The U-joint’s flexibility allows mechanics to apply torque at a 30-degree angle, reducing labor time by up to 40%. In industrial robotics, socket-U-joint systems enable precise torque application in robotic arm joints, where multi-directional movement is essential for manufacturing tasks. This adaptability ensures seamless operation in tight production lines.

FAQ Section

Q1: How does a universal joint enhance a socket’s functionality?

A universal joint allows the socket to operate at angles, making it easier to access fasteners in constrained or irregularly shaped spaces. This flexibility is unmatched by traditional rigid tools.

Q2: What industries rely most on socket and universal joint combinations?

Automotive, robotics, HVAC, and heavy machinery industries benefit most. These sectors demand torque transmission in environments where angular misalignment is common.

Q3: Can a socket U-joint combination be used in DIY projects?

Yes, but only for tasks requiring moderate torque and angular access, such as assembling furniture or performing car maintenance. Always use tools rated for your specific project to avoid damage or injury.

Q4: How do I prevent damage to the universal joint in a socket assembly?

Avoid over-tightening beyond the tool’s capacity and stick to recommended lubrication intervals. Regularly inspect the joint’s angle to ensure it’s within operational limits.

Q5: How does this combination compare to other flexible tools (e.g., swivel heads)?

Socket-U-joint combos handle higher torque loads but require more skill to use effectively. Swivel heads are easier for casual tasks but lack the same durability in heavy-duty applications.

Conclusion

The combination of sockets and universal joints is a game-changer for mechanical tasks requiring flexibility and precision. From automotive repairs to industrial automation, this duo enhances efficiency, reduces wear, and adapts to complex environments. By understanding their mechanics, selecting the right configuration, and maintaining them properly, you can ensure reliable performance. For intricate projects, consider investing in specialized tools or consulting experts to maximize the potential of this versatile partnership.