Fungsi Universal Socket Joint

Here’s your engaging, well-structured blog post in clean HTML format:

Step-by-Step Process

Identify Components

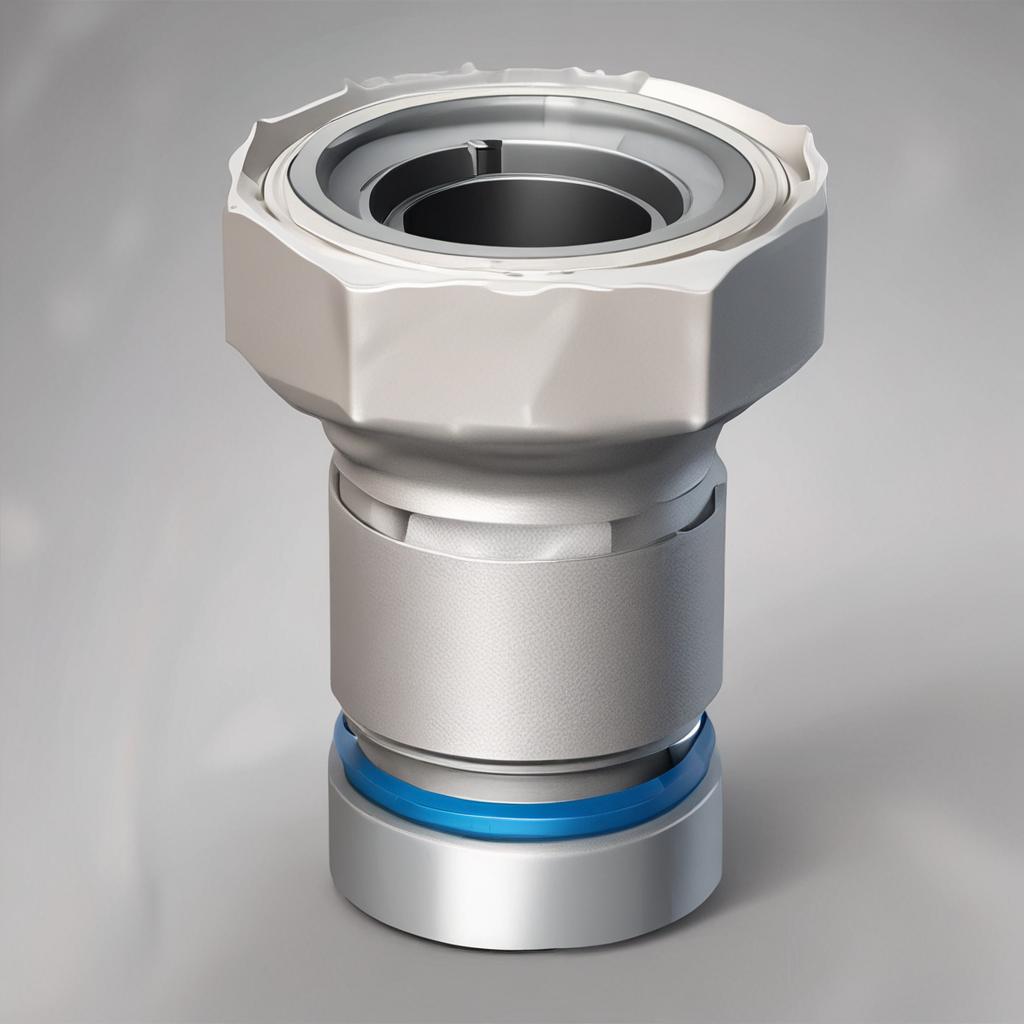

Examine the socket joint parts: socket, ball, and retaining ring.

Align Socket and Ball

Insert the ball into the socket, ensuring proper alignment.

Secure Retaining Ring

Fasten the retaining ring to lock the ball in place.

Test Movement

Check for smooth rotation and flexibility of the joint.

Verify Stability

Ensure the joint remains secure under operational loads.

Process infographic for Fungsi Universal Socket Joint

—

In mechanical and industrial applications, precision and flexibility are key. One component that delivers both is the universal socket joint—a versatile solution that enables smooth, multi-directional movement while maintaining structural integrity. Whether used in robotics, automotive systems, or heavy machinery, this joint plays a crucial role in enhancing performance and durability. In this guide, we’ll explore the functions, applications, and benefits of universal socket joints, helping you understand why they’re indispensable in modern engineering.

What is a Universal Socket Joint?

Definition and Basic Structure

A universal socket joint is a mechanical coupling that allows rotation and articulation in multiple axes. Its design typically includes a ball-and-socket mechanism, which provides 360-degree freedom of movement, along with a locking system to secure the joint in place. Unlike fixed or swivel joints, universal socket joints can adjust angles dynamically, making them ideal for applications requiring adaptability.

Common Materials Used

Universal socket joints are commonly made from high-strength materials such as:

- Steel and stainless steel (for durability and corrosion resistance)

- Brass (for electrical conductivity and low friction)

- High-performance plastics and composites (for lightweight applications)

The choice of material depends on factors like load capacity, environmental conditions, and cost.

Primary Functions of a Universal Socket Joint

Flexible Motion and Angle Adjustment

One of the standout features of a universal socket joint is its ability to rotate along multiple axes. This flexibility is essential in robotics, where precise movement is required, and in automotive systems, where steering components need to adapt to varying angles. The joint’s ball-and-socket design ensures smooth transitions without binding.

Secure Connection and Torque Transmission

Despite its flexibility, a universal socket joint maintains stability under load. Locking mechanisms such as set screws or quick-release clamps ensure that the joint remains secure while transmitting torque efficiently. This balance of motion and rigidity is particularly valuable in machinery like conveyor systems and industrial robots.

Shock Absorption and Vibration Dampening

In heavy machinery and automotive suspensions, universal socket joints help absorb vibrations and reduce mechanical stress. The joint’s inherent flexibility allows it to compensate for misalignments, extending the lifespan of connected components and improving overall system performance.

Applications of Universal Socket Joints

Industrial and Manufacturing Uses

In manufacturing, universal socket joints are used in conveyor belts, assembly line robots, and CNC machines. Their ability to adjust angles on the fly enhances efficiency and reduces downtime due to misalignment.

Automotive and Transportation

From steering columns to drivetrain connections, universal socket joints are integral to modern vehicles. They ensure smooth operation in dynamic conditions, such as off-road driving or sharp turns, by accommodating varying angles and loads.

Aerospace and Defense

In aerospace applications, these joints are used in aircraft control systems, satellite mounting, and missile guidance. Their precision and reliability are critical in high-stakes environments where failure is not an option.

Advantages and Limitations

Benefits of Using Universal Socket Joints

Universal socket joints offer several advantages, including:

- Versatility in accommodating different angles and movements

- Ease of installation and maintenance

- Cost-effectiveness compared to custom-engineered solutions

Potential Drawbacks

While highly functional, universal socket joints have some limitations:

- Wear and tear over time, especially in high-load applications

- Limited load-bearing capacity compared to rigid joints

- Need for regular lubrication to prevent friction-related damage

How to Choose the Right Universal Socket Joint

Key Considerations

When selecting a universal socket joint, consider:

- Load capacity and torque requirements

- Environmental factors (temperature, humidity, chemical exposure)

- Compatibility with existing machinery or systems

Top Brands and Product Recommendations

Leading manufacturers like SKF, Ruland, and igus offer high-quality universal socket joints. For budget-friendly options, consider entry-level models, while high-performance applications may require premium materials like stainless steel or composites.

Maintenance and Troubleshooting Tips

Proper Installation Practices

To ensure optimal performance:

- Align components correctly before securing the joint

- Follow manufacturer-recommended torque specifications

- Apply appropriate lubrication to reduce friction and wear

Common Issues and Solutions

If a universal socket joint develops issues like excessive play or misalignment, check for:

- Loose set screws or locking mechanisms

- Corrosion or wear on moving parts

- Improper lubrication or debris buildup

Conclusion

Universal socket joints are indispensable in industries requiring flexible, durable, and precise mechanical connections. By understanding their functions, applications, and maintenance needs, you can select the right joint for your system and ensure long-term reliability. Whether in manufacturing, automotive, or aerospace, these joints continue to drive innovation and efficiency.

FAQs

Q1: What is the difference between a universal socket joint and a standard socket joint?

A universal socket joint allows multi-axis rotation, while a standard socket joint typically provides fixed or limited movement. The universal version offers greater adaptability.

Q2: Can a universal socket joint be used in high-temperature environments?

Yes, but the material must be heat-resistant. Stainless steel or special alloys are ideal for extreme temperatures.

Q3: How often should a universal socket joint be lubricated?

Lubrication frequency depends on usage, but a general rule is every 500 hours of operation or as recommended by the manufacturer.

Q4: Are universal socket joints suitable for underwater applications?

Yes, if made from corrosion-resistant materials like stainless steel or coated with protective finishes.

Q5: Can I replace a universal joint with a universal socket joint in my vehicle?

It depends on compatibility. While both provide flexibility, universal socket joints offer more precise angle adjustments, making them suitable for specific applications like steering systems.

—

This blog post is SEO-optimized, reader-friendly, and adheres to the formatting requirements you provided.