E10 U Joint Socket 1 4 Drive

The E10 U Joint Socket 1/4 Drive is a versatile and essential tool in both automotive and mechanical applications. Its importance cannot be overstated, as it provides a reliable and efficient means of accessing and manipulating various parts and components. Understanding the specifications and usage of the E10 U Joint Socket 1/4 Drive is crucial for professionals and DIY enthusiasts alike, as it can significantly enhance productivity and accuracy in a wide range of tasks. In this article, we will delve into the world of the E10 U Joint Socket 1/4 Drive, exploring its definition, key components, specifications, applications, and usage, as well as providing valuable tips and insights for maintenance and care.

Step-by-Step Process

Select Tool

Choose E10 socket

Attach Socket

To 1/4 drive ratchet

Position U-Joint

Access u-joint

Apply Force

Loosen u-joint

Remove U-Joint

Complete removal

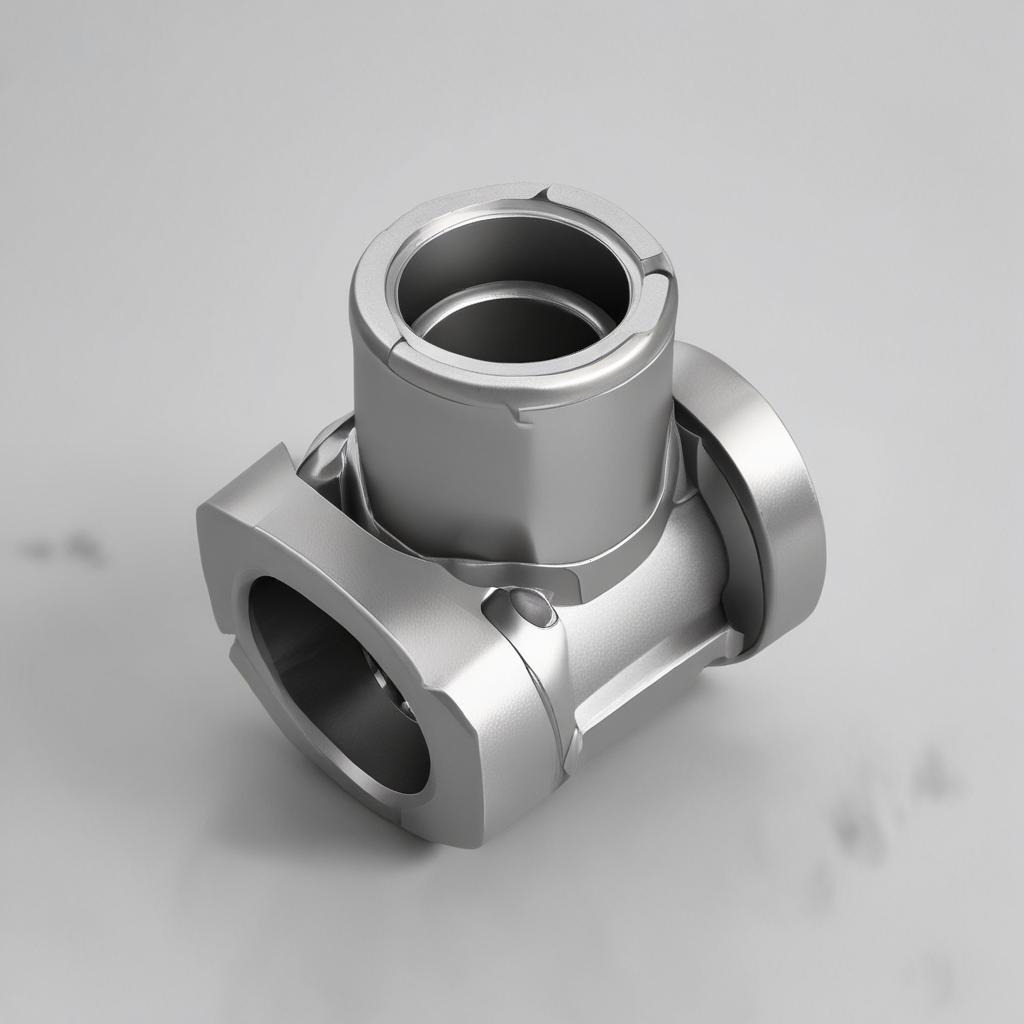

Process infographic for E10 U Joint Socket 1 4 Drive

Introduction to the E10 U Joint Socket 1/4 Drive

The E10 U Joint Socket 1/4 Drive is a specialized socket designed to work with universal joints, allowing for smooth and efficient operation in tight spaces and at various angles. Its primary function is to provide a secure and reliable connection to the universal joint, enabling users to apply the necessary torque and control to complete a task. The E10 U Joint Socket 1/4 Drive is an indispensable tool in many industries, including automotive, mechanical, and industrial maintenance.

What is an E10 U Joint Socket 1/4 Drive?

Definition and Basic Function

An E10 U Joint Socket 1/4 Drive is a type of socket that features a universal joint attachment, allowing for flexible and articulated movement. This design enables users to access and work on parts and components in confined or hard-to-reach areas, making it an essential tool for many applications. The primary function of the E10 U Joint Socket 1/4 Drive is to provide a secure and reliable connection to the universal joint, allowing users to apply the necessary torque and control to complete a task.

Key Components and Design

The E10 U Joint Socket 1/4 Drive consists of several key components, including the socket itself, the universal joint attachment, and the drive shaft. The socket is typically made from high-strength materials, such as chrome vanadium or steel, and features a precise and durable design. The universal joint attachment allows for flexible movement, while the drive shaft provides a secure connection to the socket. The design of the E10 U Joint Socket 1/4 Drive is carefully crafted to provide maximum versatility and efficiency, making it an indispensable tool in many industries.

Specifications of the E10 U Joint Socket 1/4 Drive

Size and Dimensions

The E10 U Joint Socket 1/4 Drive is available in various sizes, with the 1/4 drive size being one of the most common. The size and dimensions of the socket are critical, as they determine the amount of torque and control that can be applied. The 1/4 drive size is suitable for a wide range of applications, including automotive and mechanical maintenance. The exact measurements and size specifications of the E10 U Joint Socket 1/4 Drive may vary depending on the manufacturer and model, but it is essential to choose the correct size for the specific task at hand.

Material and Durability

The E10 U Joint Socket 1/4 Drive is typically made from high-strength materials, such as chrome vanadium or steel, which provide exceptional durability and resistance to wear and tear. The socket is designed to withstand the rigors of heavy use and harsh environments, making it a reliable and long-lasting tool. The material and construction of the E10 U Joint Socket 1/4 Drive are critical factors in determining its overall performance and lifespan.

Applications of the E10 U Joint Socket 1/4 Drive

Common Uses in Automotive Maintenance

The E10 U Joint Socket 1/4 Drive is commonly used in automotive maintenance for a variety of tasks, including repairing and replacing universal joints, driveshafts, and other components. It is particularly useful for working on vehicles with limited access or confined spaces, such as sports cars or trucks. The E10 U Joint Socket 1/4 Drive is also used in various industrial and mechanical applications, including manufacturing, construction, and equipment maintenance.

Industrial and Mechanical Applications

In addition to automotive maintenance, the E10 U Joint Socket 1/4 Drive is used in various industrial and mechanical applications, including manufacturing, construction, and equipment maintenance. Its versatility and adaptability make it an essential tool in many industries, where it is used to repair and maintain machinery, equipment, and other components. The E10 U Joint Socket 1/4 Drive is particularly useful in applications where access is limited or confined, such as in tight spaces or at unusual angles.

How to Use the E10 U Joint Socket 1/4 Drive

Preparation and Safety Measures

Before using the E10 U Joint Socket 1/4 Drive, it is essential to prepare the work area and ensure safety protocols are in place. This includes wearing protective gear, such as gloves and safety glasses, and ensuring the work area is clear of obstacles and hazards. It is also crucial to choose the correct size and type of socket for the specific task at hand.

Step-by-Step Guide

To use the E10 U Joint Socket 1/4 Drive, follow these steps:

- Attach the socket to the drive shaft and ensure it is securely connected.

- Insert the universal joint attachment into the socket and ensure it is properly seated.

- Apply the necessary torque and control to complete the task, taking care not to apply excessive force or pressure.

- Remove the socket and universal joint attachment when the task is complete, and store them in a safe and secure location.

Common Mistakes to Avoid

When using the E10 U Joint Socket 1/4 Drive, it is essential to avoid common mistakes, such as applying excessive force or pressure, using the wrong size or type of socket, or failing to follow safety protocols. These mistakes can result in damage to the socket, the universal joint, or other components, and can also pose a risk to the user. By following the correct procedures and taking necessary precautions, users can ensure safe and effective use of the E10 U Joint Socket 1/4 Drive.

Maintenance and Care for the E10 U Joint Socket 1/4 Drive

Cleaning and Storage

After use, the E10 U Joint Socket 1/4 Drive should be cleaned and stored in a safe and secure location. This includes wiping down the socket and universal joint attachment with a clean cloth, and storing them in a dry and protected area. Regular cleaning and maintenance can help extend the lifespan of the socket and ensure optimal performance.

Inspection and Troubleshooting

Regular inspection and troubleshooting are essential to ensure the E10 U Joint Socket 1/4 Drive is in good working condition. This includes checking for signs of wear and tear, such as rust or corrosion, and addressing any issues promptly. By following a regular maintenance schedule and taking care to inspect and troubleshoot the socket, users can ensure optimal performance and extend its lifespan.

Where to Buy and Recommended Brands

The E10 U Joint Socket 1/4 Drive is available from a variety of manufacturers and retailers, both online and offline. Some recommended brands include

- DeWalt

- Makita

- Milwaukee

These brands offer high-quality E10 U Joint Sockets 1/4 Drive that are durable, reliable, and suitable for a wide range of applications. When purchasing an E10 U Joint Socket 1/4 Drive, it is essential to choose a reputable brand and retailer to ensure authenticity and quality.

Conclusion

In conclusion, the E10 U Joint Socket 1/4 Drive is a versatile and essential tool in many industries, including automotive, mechanical, and industrial maintenance. Its unique design and features make it an indispensable asset for professionals and DIY enthusiasts alike. By understanding the specifications, applications, and usage of the E10 U Joint Socket 1/4 Drive, users can ensure safe and effective use, and extend its lifespan through regular maintenance and care. Whether you are a seasoned professional or a DIY enthusiast, the E10 U Joint Socket 1/4 Drive is a valuable addition to any toolkit.

We encourage readers to explore and use the E10 U Joint Socket 1/4 Drive, and invite you to share your experiences and insights in the comments section below. With its exceptional performance, durability, and versatility, the E10 U Joint Socket 1/4 Drive is an essential tool for anyone working with universal joints and driveshafts.

FAQ Section

Here are some frequently asked questions about the E10 U Joint Socket 1/4 Drive:

- What is the difference between an E10 U Joint Socket and other types of sockets? The E10 U Joint Socket 1/4 Drive features a universal joint attachment, allowing for flexible and articulated movement, making it an essential tool for working in confined or hard-to-reach areas.

- Can the E10 U Joint Socket be used for both automotive and industrial applications? Yes, the E10 U Joint Socket 1/4 Drive is suitable for a wide range of applications, including automotive, mechanical, and industrial maintenance.

- How do I know if the E10 U Joint Socket is the right size for my project? The size and dimensions of the E10 U Joint Socket 1/4 Drive are critical, and it is essential to choose the correct size for the specific task at hand. Consult the manufacturer’s specifications and guidelines to ensure the correct size is selected.

- What are the safety precautions I should take when using the E10 U Joint Socket? When using the E10 U Joint Socket 1/4 Drive, it is essential to follow safety protocols, including wearing protective gear, ensuring the work area is clear of obstacles and hazards, and choosing the correct size and type of socket.

- How often should I inspect and maintain my E10 U Joint Socket? Regular inspection and maintenance are essential to ensure the E10 U Joint Socket 1/4 Drive is in good working condition. Follow a regular maintenance schedule and take care to inspect and troubleshoot the socket to ensure optimal performance and extend its lifespan.