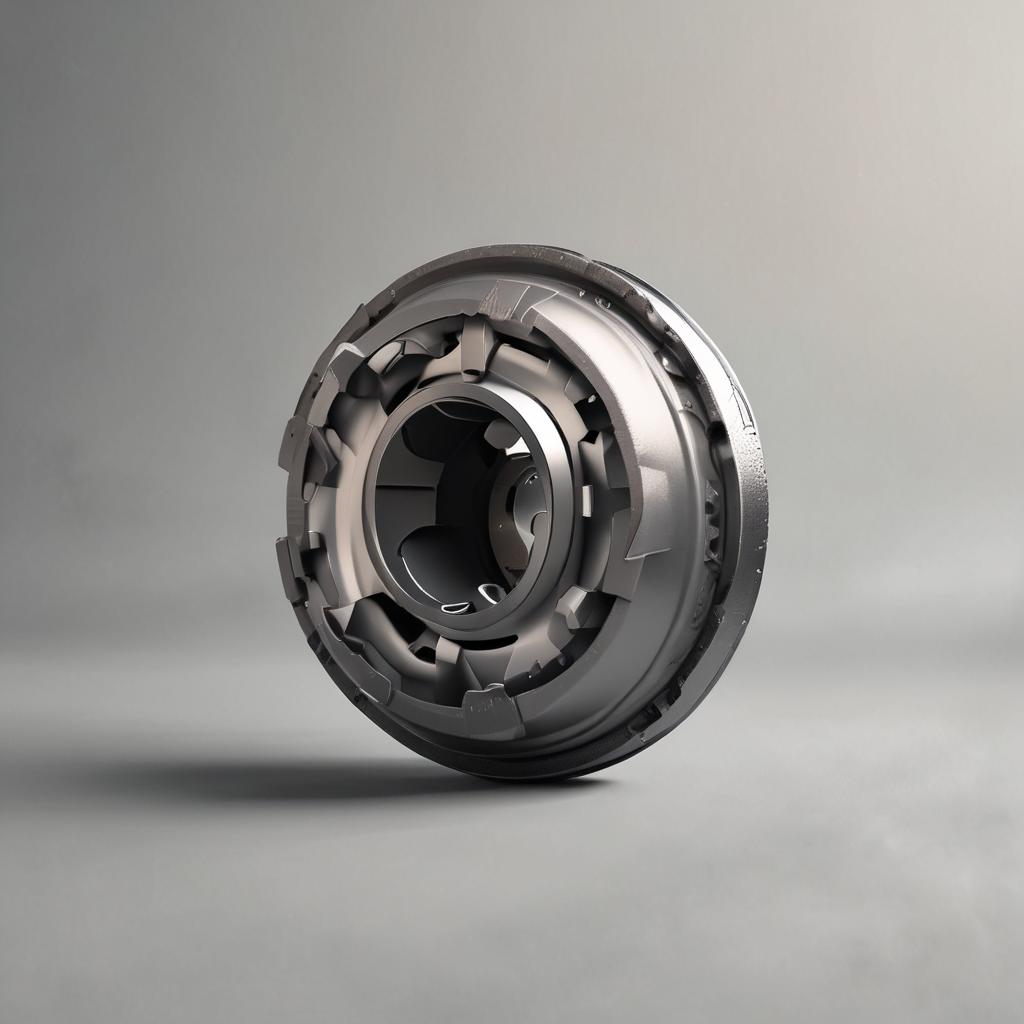

Broken Impact Socket

Impact sockets are essential tools in automotive and mechanical work, designed to withstand the high torque generated by impact wrenches. However, a broken impact socket can lead to significant safety hazards, project delays, and costly repairs. Understanding the causes of breakage, implementing prevention strategies, and knowing how to address the issue when it occurs are crucial for maintaining a safe and efficient workspace. This article explores the common causes of broken impact sockets, offers practical solutions, and provides tips for selecting durable tools to avoid future problems.

Common Causes of a Broken Impact Socket

Using Low-Quality or Inappropriate Materials

Standard sockets are often made from chrome vanadium steel, while impact sockets are crafted from chrome moly steel, which is more resistant to high torque. Using low-quality or inappropriate materials can result in cracks, shattering, or deformation under stress. Always opt for impact-rated sockets to ensure durability and safety.

Over-Tightening or Overloading the Socket

Exceeding the torque limits of an impact socket can cause it to fail. Misusing tools, such as using a regular wrench for impact tasks, can also lead to breakage. Always adhere to the manufacturer’s torque guidelines and use the correct tools for the job.

Corrosion, Debris, or Contamination

Rust, grit, or dirt between the socket and fastener can weaken the tool and increase the risk of breakage. Regularly cleaning your sockets before use can prevent contamination and extend their lifespan.

Reusing Damaged Sockets

Minor cracks or deformations can escalate into full breakage if ignored. Regular inspections and replacing compromised sockets are essential to avoid accidents and ensure consistent performance.

Incorrect Installation or Alignment

Cross-threading, improper fit, or misalignment during use can create stress fractures in the socket. Ensuring proper installation and alignment, as well as choosing the correct socket depth and hexagonal fit, can prevent breakage.

Prevention Strategies to Extend Impact Socket Lifespan

Select High-Quality Impact-Rated Sockets

Invest in high-quality impact-rated sockets from trusted brands with certifications like ASME or ISO. While these tools may cost more upfront, their durability and reliability make them a worthwhile investment.

Match Sockets to the Task and Tool

Choose the correct size, drive type (1/4”, 3/8”, 1/2”), and application (metric vs. SAE) for your sockets. Avoid mixing impact sockets with hand tools to prevent damage.

Essential Checklist

Goal Definition

Clearly define objectives and success metrics

Resource Planning

Allocate necessary time, budget, and personnel

Implementation Strategy

Develop step-by-step execution plan

Quality Assurance

Establish testing and validation procedures

Performance Monitoring

Set up tracking and reporting systems

Essential items for Broken Impact Socket

Regular Maintenance and Inspection

Clean, lubricate, and store your sockets properly to prevent wear. Routinely check for cracks, rounding edges, or wall thinning to catch issues early.

Avoid Over-Torquing and Follow Guidelines

Use impact wrenches at appropriate torque settings and always read the manufacturer’s specifications. Over-torquing can lead to socket failure and other complications.

Handle Sockets with Care

Avoid dropping, prying, or using sockets as hammers. Proper handling minimizes accidental stress and extends the tool’s lifespan.

What to Do When Your Impact Socket Breaks

Immediate Safety and Damage Assessment

Secure the workspace and check for hazards, such as broken socket pieces in the engine. Assess the situation to determine the best course of action.

Removing a Broken Socket from a Fastener

Use methods like a socket extractor, drilling, or heat application (if safe) to remove a broken socket. Avoid DIY methods that could damage surrounding components.

Repairing or Replacing the Socket

In some cases, welding may be an option for repairs, but replacement is often the safer and more cost-effective choice. Evaluate the costs and time considerations before deciding.

Preventing Future Breakages

Learn from the incident by identifying the cause of breakage, such as tool misuse or low-quality materials. Upgrade your equipment or adjust maintenance routines to avoid recurrence.

How to Choose a Durable and Reliable Impact Socket

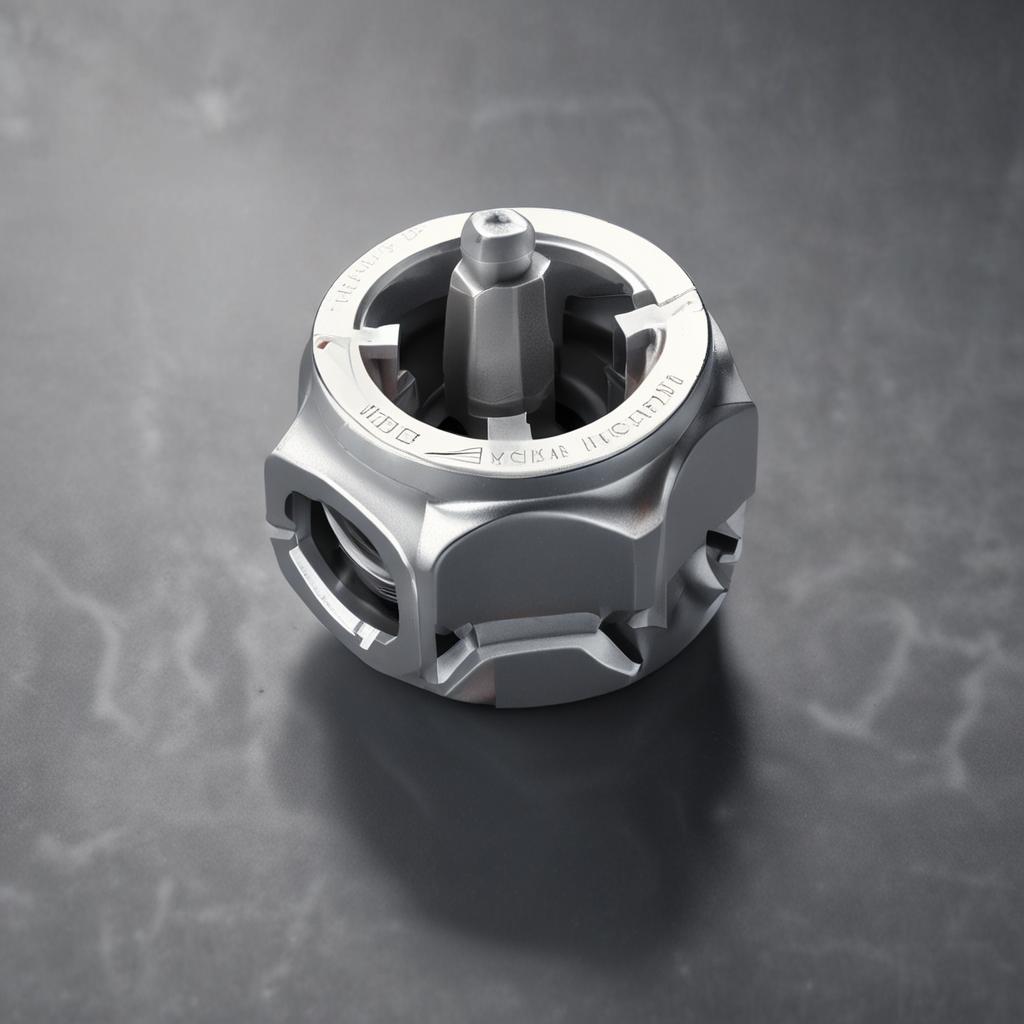

Material Matters: Opt for Chrome Moly Steel

Chrome moly steel (SAE J462) is the preferred material for impact sockets due to its strength and resilience. Heat-treated designs further enhance durability.

Size and Compatibility Check

Ensure precise sizing to avoid overloading or slippage. Verify drive size compatibility with your impact wrench and fasteners.

Brand Reputation and User Reviews

Research brands with a history of producing rugged tools. Read user reviews to identify common issues or praises before making a purchase.

Additional Features for Longevity

Look for features like rounded edges, thin walls for deep access, and impact-specific designs (e.g., 6-point vs. 12-point sockets). Anti-slip coatings or markings can also improve usability.

Conclusion: Avoiding and Addressing Broken Impact Sockets

Preventing broken impact sockets starts with selecting high-quality tools, using them correctly, and maintaining them regularly. When breakage occurs, prompt action and proper assessment are key to resolving the issue safely. Investing in reliable impact sockets not only ensures safety but also enhances efficiency in automotive and mechanical work. By following these guidelines, you can minimize the risk of breakage and maximize the lifespan of your tools.

FAQ Section: Frequently Asked Questions About Broken Impact Sockets

Can a broken impact socket be repaired?

Repair options like welding may be feasible in some cases, but replacement is often the safer and more cost-effective choice.

What are the signs a socket is about to break?

Early warning signs include cracks, deformation, or slippage during use.

Are impact sockets interchangeable with regular sockets?

No, regular sockets are not designed to handle the high torque of impact wrenches and can break under stress.

How often should impact sockets be replaced?

Replace impact sockets based on usage frequency and visible wear, such as cracks or wall thinning.

What’s the best material for high-torque applications?

Chrome moly steel is the preferred material for high-torque applications due to its strength and durability.