Best Universal Joint for Trucks

Universal joints, or U-joints, are critical components in a truck’s drivetrain, ensuring smooth power transfer from the transmission to the wheels. These joints allow for flexibility between shafts, accommodating movement as the suspension shifts and the vehicle navigates uneven terrain. However, not all U-joints are created equal, and selecting the right one can significantly impact your truck’s performance, safety, and longevity. Whether you’re a fleet manager or a truck enthusiast, understanding the key factors, types, and brands of U-joints will help you make an informed decision and keep your vehicle running reliably.

What is a Universal Joint and Why is it Important for Trucks?

Definition and Function of a Universal Joint

A universal joint is a mechanical coupling that connects two shafts at an angle, allowing them to rotate independently while transmitting torque. In trucks, it’s typically found in the driveshaft, linking the transmission to the rear axle or transfer case. Its design accommodates angular movement, which is essential for maintaining power flow as the vehicle’s frame and suspension shift during operation.

Significance of U-Joints in Truck Performance

A high-quality U-joint ensures efficient power transfer, minimizing energy loss and preventing drivetrain vibrations. Worn or damaged U-joints can lead to clunking noises, uneven wear on other components, and even complete driveline failure. For trucks used in heavy-duty tasks like towing or off-roading, a reliable U-joint is non-negotiable to avoid breakdowns and costly repairs.

Key Factors to Consider When Choosing the Best Universal Joint

Material and Durability

Materials like heat-treated steel and durable alloys are vital for withstanding the stress of heavy loads. Greaseable designs, which allow for periodic lubrication, often outlast non-greaseable alternatives by reducing friction and wear over time.

Compatibility with Truck Model

U-joints must match your truck’s specifications precisely. Consult the owner’s manual or a mechanic to ensure the joint fits the driveshaft and aligns with the vehicle’s drivetrain geometry. Universal joints are not one-size-fits-all, and incorrect sizing can cause misalignment and mechanical issues.

Load Capacity and Strength

Trucks used for towing or hauling require U-joints rated for higher torque and load. Check the joint’s capacity to handle your vehicle’s horsepower and the weight it regularly carries. Choosing a joint with a higher rating than needed can provide a safety buffer.

Maintenance Requirements

Greaseable U-joints need regular lubrication to function optimally, while non-greaseable versions are sealed but may require replacement sooner under heavy use. Consider your maintenance preferences and the truck’s operating conditions when deciding between the two.

Brand Reputation and Reviews

Opt for brands with a proven track record in automotive components. Customer reviews can highlight real-world performance, noise levels, and durability. Prioritize brands that offer warranties, as this reflects confidence in their product quality.

Top Universal Joint Brands for Trucks

Spicer

Spicer is synonymous with OEM-quality U-joints, offering robust solutions for both light and heavy-duty trucks. Their products are engineered for precision and are trusted in commercial and industrial applications.

Moog

Moog combines affordability with precision engineering, providing U-joints that deliver smooth operation and long-term reliability. They’re a popular choice for DIY enthusiasts and professionals alike.

Neapco

Neapco specializes in innovative, heavy-duty U-joints designed for extreme conditions. Their advanced bearing technology reduces vibration and enhances driveline efficiency, making them ideal for off-road and towing scenarios.

Dana

Dana’s U-joints leverage decades of drivetrain expertise, offering durability and smooth performance. They’re known for their compatibility with a wide range of truck models, including older and modified vehicles.

Other Notable Brands

Brands like Precision and GMB also provide high-quality U-joints, balancing cost and performance. Precision is favored for its robust construction, while GMB offers lightweight yet durable options for modern trucks.

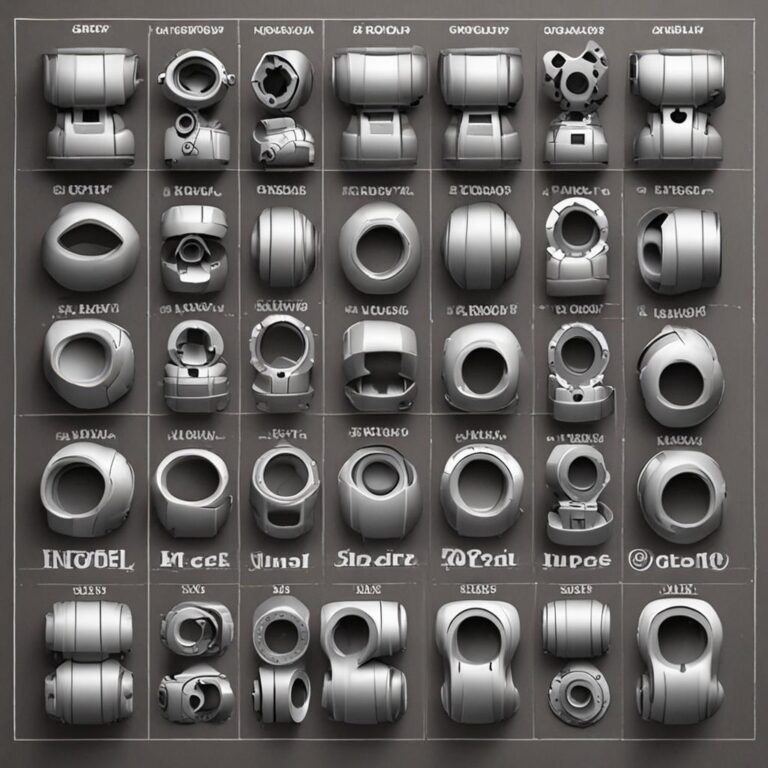

Types of Universal Joints for Trucks

Cross and Bearing U-Joints

The standard cross and bearing design uses a cross-shaped yoke and needle bearings to allow rotational movement. It’s widely used in trucks for its simplicity and effectiveness in handling angular misalignment.

Double Cardan U-Joints

Double Cardan joints feature two U-joints in one housing, minimizing vibration and balancing speed in applications with extreme driveline angles. They’re common in specialty trucks and vehicles with high-performance requirements.

Greaseable vs. Non-Greaseable U-Joints

Comparison table for Greaseable vs. Non-Greaseable U-Joints

Greaseable U-joints have a Zerk fitting for regular lubrication, extending their lifespan. Non-greaseable versions are sealed for low maintenance but may require more frequent replacements in high-stress environments.

How to Maintain and Extend the Life of Your Universal Joint

Regular Inspection and Lubrication

Inspect U-joints every 10,000–15,000 miles for play, rust, or damaged bearings. For greaseable types, use a lubrication pump with the correct grease to keep components running smoothly.

Signs of a Failing U-Joint

Watch for clunking or knocking sounds over bumps, vibrations at certain speeds, or grease leaks around the joint. Excessive movement in the driveshaft when lifted off the ground is another red flag.

Replacement Tips

Replace U-joints as a pair (both front and rear) to maintain drivetrain balance. Use a press tool for installation and ensure proper alignment. Always torque components to manufacturer specifications to avoid premature wear.

Conclusion

Choosing the best universal joint for your truck is essential for maintaining power transfer efficiency and preventing mechanical failures. By prioritizing durability, compatibility, and maintenance needs, you can ensure your vehicle performs reliably under demanding conditions. If unsure, consult a trusted mechanic or explore reputable brands like Spicer, Moog, or Neapco to find a solution tailored to your truck’s requirements.

FAQs About Universal Joints for Trucks

1. What is the average lifespan of a universal joint in a truck?

- Under normal conditions, U-joints last 50,000–100,000 miles. Harsh use, lack of lubrication, or poor installation can shorten their life significantly.

2. Can I replace a U-joint myself, or should I hire a professional?

- Basic replacement is feasible for experienced DIYers with the right tools. However, alignment and balancing require technical skill, so professionals are recommended for complex cases.

3. What’s the difference between a greaseable and non-greaseable U-joint?

- Greaseable models require regular lubrication to reduce friction and extend life. Non-greaseable versions are maintenance-free but may degrade faster in high-stress environments.

4. How do I know if my truck’s U-joint is failing?

- Listen for clunking noises, feel vibrations at specific speeds, and check for visible wear or grease leaks. A play of more than 0.04 inches in the joint is a clear sign of replacement needed.

5. Are universal joints universal, or do they vary by truck model?

- U-joints are not truly universal. Each truck model requires a joint with precise dimensions and specifications. Always verify compatibility with your vehicle’s make, model, and year.