Axle Nut Socket Size Chart

When it comes to vehicle maintenance, even the smallest details can make a big difference. One such detail is knowing the correct axle nut socket size for your car, truck, or SUV. Axle nuts play a crucial role in securing the wheel hub to the axle, ensuring your vehicle operates safely and smoothly. Using the wrong socket size can lead to stripped threads, damaged fasteners, or even accidents. Whether you’re a seasoned mechanic or a DIY enthusiast, this comprehensive guide will walk you through everything you need to know about axle nut socket sizes, including how to determine the right size, a detailed chart, and tips for proper installation.

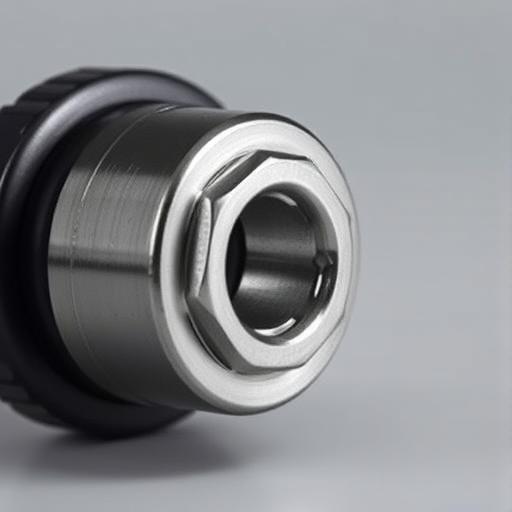

Step-by-Step Process

Identify Axle Nut

Determine the type and size of the axle nut to be removed.

Consult Chart

Refer to the axle nut socket size chart for the correct tool.

Select Socket

Choose the socket that matches the nut’s size and shape.

Attach to Tool

Secure the socket to a breaker bar or torque wrench.

Remove Nut

Apply force to loosen and remove the axle nut safely.

Process infographic for Axle Nut Socket Size Chart

Introduction to Axle Nut Socket Sizes

Axle nuts are critical components that hold the wheel assembly together, ensuring stability and safety while driving. They are typically tightened to high torque specifications, making it essential to use the correct socket size during installation or removal. Using the wrong size can damage the nut, compromise the wheel’s integrity, or even lead to accidents. Socket sizes are generally categorized into two systems: metric and standard. Metric sizes (e.g., 36mm) are commonly used in modern vehicles, while standard sizes (e.g., 1-1/8″) are often found in older or classic models. Understanding these systems is the first step toward proper maintenance.

How to Determine Your Axle Nut Socket Size

Check Your Vehicle’s Owner Manual

The easiest way to find the correct axle nut socket size is by consulting your vehicle’s owner manual. Most manuals include a section dedicated to wheel and axle specifications, including the size of the axle nut. Following the manufacturer’s guidelines ensures accuracy and prevents potential damage to your vehicle.

Use a Socket Size Chart by Vehicle Make/Model

If you don’t have access to the owner’s manual, a socket size chart organized by vehicle make, model, and year can be a helpful resource. For example, a Ford F-150 might require a 36mm socket, while a Toyota Corolla could use a 32mm. Cross-referencing your vehicle’s details with a reliable chart can save time and effort.

Measure the Axle Nut Yourself

For those who prefer a hands-on approach, measuring the axle nut directly is another option. Using a caliper or ruler, measure the width and height of the nut to determine its size. Pay close attention to similar sizes, such as 36mm vs. 38mm, to ensure accuracy. This method is particularly useful for older or modified vehicles where specifications may not be readily available.

Comprehensive Axle Nut Socket Size Chart

Metric Socket Sizes for Axle Nuts

Metric socket sizes are widely used in modern vehicles. Common sizes include 14mm, 17mm, 19mm, 21mm, 24mm, 30mm, 32mm, and 36mm. These sizes are typically found in passenger cars, light trucks, and SUVs. For example, a Honda Civic might require a 32mm socket, while a Toyota RAV4 could use a 36mm.

Standard Socket Sizes for Axle Nuts

Standard socket sizes, measured in inches, are often used in older or classic vehicles. Common sizes include 9/16″, 5/8″, 3/4″, 1″, and 1-1/8″. For instance, a 1960s Ford Mustang might require a 1-1/8″ socket. These sizes are less common in newer models but remain essential for vintage car maintenance.

Cross-Reference Chart (Metric to Standard)

Sometimes, you may need to convert between metric and standard sizes. For example, 36mm is approximately 1.417 inches, which is closest to a 1-1/4″ standard socket. Import vehicles typically use metric sizes, while domestic vehicles may use standard or metric depending on the year and model.

Axle Nut Socket Size Chart by Vehicle Type

Compact Cars (2000–Present)

Compact cars like the Honda Civic and Toyota Corolla often use axle nut sizes such as 32mm or 36mm. These sizes are relatively small, making them easy to work with for most DIY enthusiasts.

SUVs and Light Trucks (2000–Present)

SUVs and light trucks, such as the Ford F-150 and Toyota RAV4, typically require larger socket sizes like 36mm, 40mm, or 1-1/8″. These sizes are designed to handle the higher torque requirements of heavier vehicles.

Heavy-Duty Trucks and Commercial Vehicles

Heavy-duty trucks and commercial vehicles often use much larger socket sizes, such as 46mm, 52mm, or 1-3/4″. These sizes are necessary to accommodate the immense torque and stress placed on the axle nuts in these vehicles.

Vintage and Classic Cars (Pre-1990)

Vintage and classic cars, like the Chevrolet Impala or 1960s Ford Mustang, typically use standard socket sizes such as 1″, 1-1/8″, or 1-1/4″. These sizes are less common in modern vehicles but remain essential for maintaining older models.

How to Use an Axle Nut Socket Size Chart Correctly

Tools You’ll Need

To use an axle nut socket size chart effectively, you’ll need a few essential tools, including a socket wrench, torque wrench, caliper or ruler, and lubricant. These tools ensure accurate measurements and proper installation.

Step-by-Step Process

- Identify the vehicle’s axle nut specifications using the owner’s manual or a socket size chart.

- Match the size to the chart based on your vehicle’s make, model, and year.

- Verify the size by measuring the axle nut if necessary.

Tips for Installing Axle Nuts

Always follow the manufacturer’s torque specifications to avoid over-tightening or under-tightening the axle nut. Use a torque wrench to ensure accuracy and prevent stripped threads. If the nut is worn or damaged, replace it immediately to maintain safety and performance.

Common Mistakes to Avoid with Axle Nut Sockets

Using the Wrong Socket Size

Using an undersized or oversized socket can damage the nut or the fastener, leading to costly repairs. Always double-check the size before starting the job.

Ignoring Torque Requirements

Over-tightening or under-tightening the axle nut can compromise the wheel’s integrity. Always use a torque wrench to meet the manufacturer’s specifications.

Forgetting to Replace Nuts After Removal

Many high-torque nuts are designed for single use. Reusing an old nut can lead to failure. Always replace the nut after removal, especially in heavy-duty applications.

Frequently Asked Questions (FAQ)

How do I find the correct axle nut size for my car?

Check the owner’s manual, use a socket size chart, or measure the nut directly.

What happens if I use the wrong socket size?

Using the wrong size can strip threads, damage the fastener, or make the wheel unsafe.

Are there universal axle nut socket sizes?

No, sizes vary by vehicle make, model, and year.

How often should axle nuts be replaced?

Replace them after removal or if they show signs of wear or damage.

Can I use a socket wrench to tighten axle nuts?

Yes, but always use a torque wrench to meet factory specifications.

Conclusion

Using the correct axle nut socket size is essential for vehicle safety and performance. Whether you’re referencing a chart, consulting your owner’s manual, or measuring the nut yourself, taking the time to verify the size can prevent costly mistakes and ensure a smooth repair process. If you’re ever unsure, don’t hesitate to consult a professional. Proper maintenance starts with the right tools and knowledge, and this guide is your first step toward mastering axle nut socket sizes.