A ____ is a Combined Socket and Universal Joint

A constant velocity joint, also known as a CV joint, is a critical component in modern vehicles and various industrial applications. It combines the functions of a socket and a universal joint to ensure smooth power transfer through a variable angle. This article will explore the definition, types, applications, maintenance, and advantages of CV joints, providing a comprehensive understanding of their importance and functionality.

Introduction to Constant Velocity Joints

A constant velocity joint, or CV joint, is a mechanical component that allows for the transmission of rotational power through a variable angle while maintaining a constant rotational speed. This is crucial in vehicles, especially in front-wheel drive and all-wheel drive systems, where the wheels need to move up and down and turn while maintaining power from the engine. Understanding the basics of CV joints is essential for anyone involved in automotive maintenance or industrial machinery operations.

What is a Constant Velocity Joint?

Definition and Function

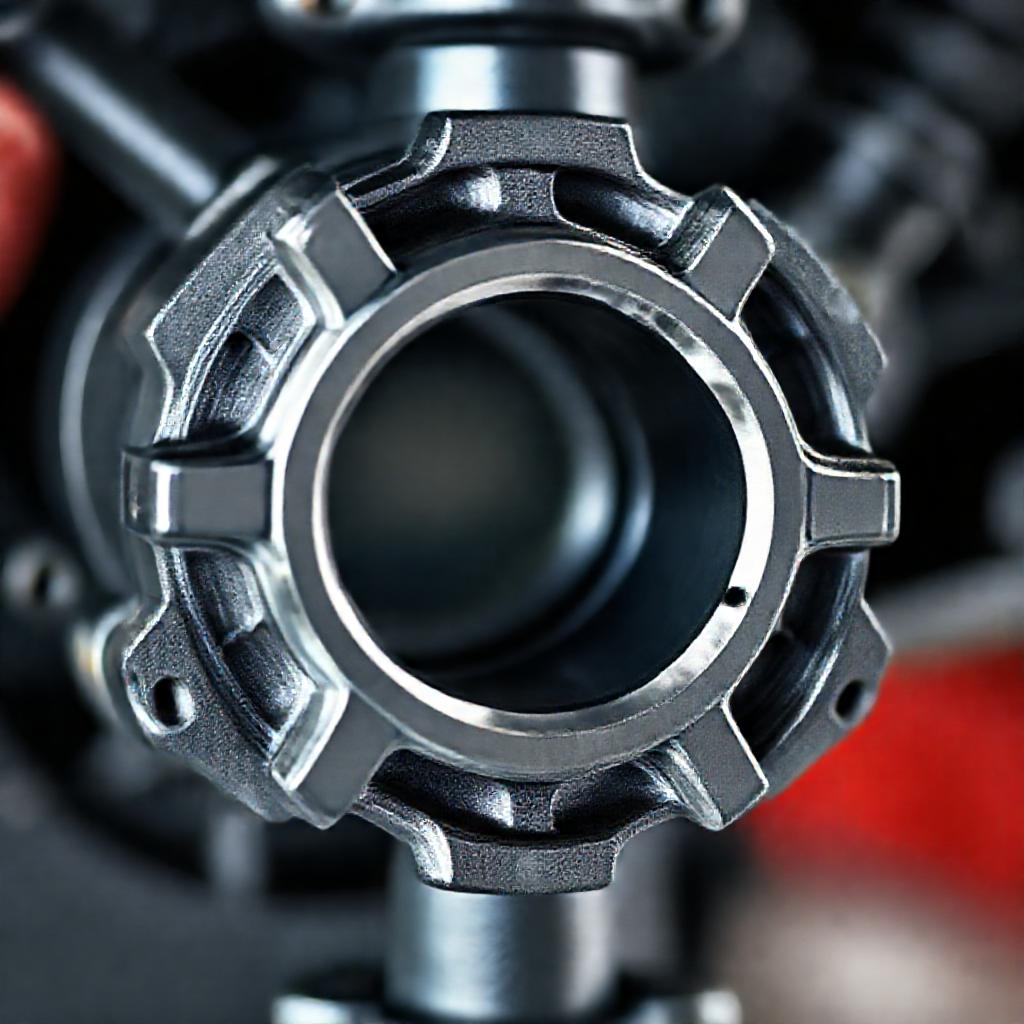

A constant velocity joint is a type of universal joint that ensures the output shaft rotates at a constant speed, regardless of the angle between the input and output shafts. This is achieved through a combination of a socket and a universal joint, which work together to minimize the effects of angular movement. The key components of a CV joint include the inner and outer races, balls, and cage, all of which are designed to work in harmony to provide smooth and efficient power transmission.

Types of Constant Velocity Joints

There are several types of CV joints, each with its own unique characteristics and applications:

- Rzeppa Joint: This type of CV joint is commonly used in front-wheel drive vehicles. It consists of a star-shaped inner race, an outer race with grooves, and six steel balls that roll between them. The Rzeppa joint is known for its ability to handle high angles and provide smooth power transfer.

- Tripod Joint: Also known as a tripod or TR joint, this type is often used in rear-wheel drive and four-wheel drive vehicles. It features a three-lobed inner race, an outer race with grooves, and three roller bearings. The tripod joint is designed to handle high torque and low angles, making it suitable for heavy-duty applications.

- Birfield Joint: This type of CV joint is commonly found in all-wheel drive and four-wheel drive vehicles. It is similar to the Rzeppa joint but is more compact and can handle higher angles. The Birfield joint is known for its durability and reliability.

Applications of Constant Velocity Joints

Automotive Applications

CV joints are widely used in the automotive industry, particularly in front-wheel drive vehicles and all-wheel drive systems. They are essential for ensuring smooth power transfer from the engine to the wheels, even when the wheels are turned or moving up and down. CV joints help improve vehicle performance, handling, and safety by maintaining a constant speed and reducing vibrations.

Essential Checklist

Goal Definition

Clearly define objectives and success metrics

Resource Planning

Allocate necessary time, budget, and personnel

Implementation Strategy

Develop step-by-step execution plan

Quality Assurance

Establish testing and validation procedures

Performance Monitoring

Set up tracking and reporting systems

Essential items for A ____ is a Combined Socket and Universal Joint

Industrial and Other Applications

Beyond the automotive sector, CV joints are also used in various industrial and mechanical applications. They are found in industrial machinery, robotics, and other systems where precise and smooth power transmission is required. CV joints are used in conveyor systems, agricultural equipment, and even in aerospace applications, where they contribute to the efficiency and reliability of the machinery.

Maintenance and Repair of Constant Velocity Joints

Signs of Wear and Failure

Recognizing the signs of wear and impending failure in CV joints is crucial for maintaining the performance and safety of your vehicle. Common signs include:

- Clicking Noises: A clicking or clunking sound when turning or accelerating can indicate a worn or damaged CV joint.

- Vibration: Excessive vibration, especially when driving at high speeds, can be a sign of a failing CV joint.

- Grease Leakage: If you notice grease leaking from the CV joint boot, it may be a sign that the boot is damaged, allowing dirt and debris to enter and cause wear.

Repair and Replacement Options

When a CV joint shows signs of wear or failure, it is important to address the issue promptly. Options for repair and replacement include:

- DIY Approaches: For those with mechanical skills, replacing a CV joint can be a DIY project. However, it requires specialized tools and a good understanding of the vehicle’s drivetrain.

- Professional Repair Services: For those who prefer a more hands-off approach, professional repair services can diagnose and replace CV joints. This option ensures that the job is done correctly and safely.

- Choosing the Right Replacement Parts: When replacing a CV joint, it is important to choose high-quality parts that match the specifications of your vehicle. Using OEM (original equipment manufacturer) parts is often recommended for the best performance and longevity.

Advantages and Limitations of Constant Velocity Joints

Benefits of Using CV Joints

CV joints offer several advantages that make them indispensable in modern vehicles and machinery:

- Maintaining Constant Velocity: CV joints ensure that the output shaft rotates at a constant speed, regardless of the angle between the input and output shafts.

- Reducing Vibration: By maintaining a constant speed, CV joints help reduce vibrations, improving the overall driving experience and the longevity of the vehicle.

- Enhancing Performance: CV joints contribute to better vehicle performance by ensuring smooth power transfer, especially in front-wheel drive and all-wheel drive systems.

Limitations and Challenges

Despite their many advantages, CV joints also have some limitations and challenges:

- Complexity: CV joints are complex mechanical components that require precise manufacturing and installation.

- Wear and Tear: Like any mechanical part, CV joints are subject to wear and tear over time, especially in high-stress applications.

- Importance of Maintenance: Regular maintenance is crucial for the longevity and performance of CV joints. Neglecting maintenance can lead to premature failure and costly repairs.

Conclusion

Constant velocity joints are essential components in modern vehicles and various industrial applications. They combine the functions of a socket and a universal joint to ensure smooth and efficient power transmission, even at varying angles. Understanding the types, applications, maintenance, and advantages of CV joints is crucial for anyone involved in automotive or industrial operations. Regular maintenance and prompt attention to signs of wear can help ensure the longevity and performance of these vital components.

FAQ

- What are the most common causes of CV joint failure?

The most common causes of CV joint failure include lack of maintenance, excessive wear and tear, and manufacturing defects. Regular inspections and timely repairs can help prevent these issues.

- How do I know if my CV joint needs to be replaced?

Signs that your CV joint may need replacement include clicking noises, vibration, and grease leakage. If you notice any of these symptoms, it is advisable to have the joint inspected by a professional.

- Can CV joints be repaired, or do they always need to be replaced?

Depending on the extent of the damage, some CV joints can be repaired. However, in many cases, replacement is necessary for optimal performance and safety. Consulting with a professional can help determine the best course of action.

- What are the benefits of upgrading to high-quality CV joints?

Upgrading to high-quality CV joints can provide improved durability, better performance, and potentially a longer vehicle lifespan. High-quality parts are often more reliable and can withstand the demands of heavy use.

- How often should CV joints be inspected and maintained?

The recommended frequency for inspecting and maintaining CV joints depends on factors like vehicle usage, mileage, and manufacturer recommendations. Regular inspections, typically during oil changes or annual maintenance, can help identify and address issues before they become serious.