Top 5 Universal Joints for Pickup Trucks in 2025 (tested)

When it comes to the performance and durability of your pickup truck, few components are as critical as the universal joint, or U-joint. These small but mighty parts play a vital role in the drivetrain system, ensuring smooth power transfer from the transmission to the wheels. Whether you’re hauling heavy loads, navigating rough terrain, or simply cruising down the highway, a reliable U-joint is essential for safety and efficiency. In this blog, we’ll dive into the top 5 universal joints for pickup trucks in 2025, tested for their reliability, strength, and overall performance, helping you make an informed decision for your vehicle.

What Are Universal Joints and Why Are They Important?

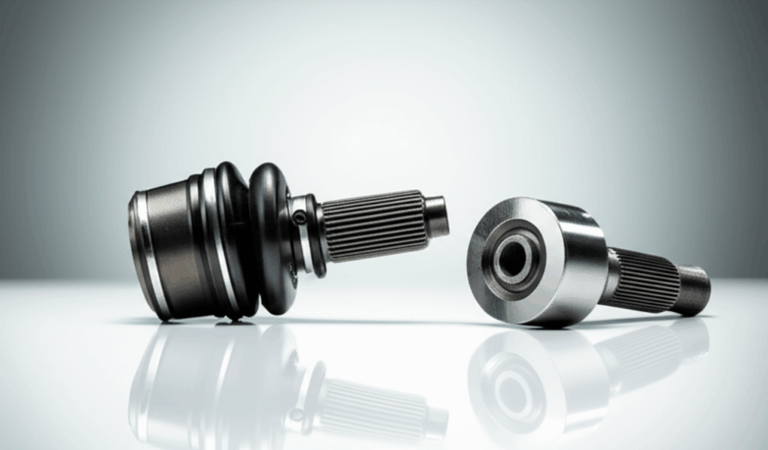

Definition and Function of Universal Joints

Universal joints, commonly known as U-joints, are mechanical components that connect the driveshaft to the axle or transmission. They allow for angular movement between these parts, enabling the driveshaft to rotate smoothly even when the axle and transmission are not perfectly aligned. This flexibility is crucial for maintaining consistent power delivery in vehicles, especially pickup trucks that often encounter uneven terrain or heavy loads.

Why U-Joints Are Critical for Pickup Trucks

Pickup trucks are built for tough jobs, from towing trailers to off-roading adventures. This heavy-duty usage places significant stress on the drivetrain, making U-joints indispensable. A high-quality U-joint ensures that your truck can handle these demands without compromising performance or safety, making it a key component for any truck owner.

Signs of a Failing U-Joint

Ignoring a failing U-joint can lead to costly repairs or even dangerous situations. Common signs include clunking noises when shifting gears, vibrations while driving, difficulty turning, or a visible wobble in the driveshaft. If you notice any of these symptoms, it’s essential to inspect and replace the U-joint as soon as possible.

Factors to Consider When Choosing a Universal Joint

Material and Build Quality

The material of a U-joint directly impacts its durability and performance. Look for options made from forged steel or high-strength alloys, as these materials can withstand the heavy loads and stress typical of pickup truck usage.

Load Capacity

Different U-joints are designed for varying levels of load capacity. If you frequently tow heavy trailers or carry substantial payloads, opt for a U-joint with a higher load rating to ensure it can handle the strain.

Compatibility

Not all U-joints are compatible with every truck model. Always check the specifications to ensure the U-joint fits your vehicle’s drivetrain system. Using an incompatible part can lead to poor performance or even damage.

Durability and Maintenance

Durability is a key factor, especially for trucks used in harsh conditions. Greasable U-joints, which allow for regular lubrication, can extend the lifespan of the component by reducing wear and tear.

Brand Reputation and Warranty

Choosing a U-joint from a reputable brand can provide peace of mind, as these companies often have a proven track record of quality and reliability. Additionally, a good warranty can protect your investment in case of defects or premature failure.

Top 5 Universal Joints for Pickup Trucks in 2025

1. Spicer 5-760X

The Spicer 5-760X is a heavy-duty U-joint designed for extreme conditions. Its forged steel construction and high load capacity make it a top choice for off-road enthusiasts and those who frequently tow heavy loads. Pros include excellent durability and ease of installation, while the only con is its slightly higher price point.

2. Moog 371

Moog’s 371 U-joint is known for its precision engineering and reliability. It features a greaseable design for easy maintenance and is compatible with a wide range of truck models. Pros include affordability and smooth performance, though it may not be as durable as some premium options.

3. Precision 344

Precision’s 344 U-joint offers a balance of strength and value. Its high-quality materials and corrosion-resistant finish ensure long-lasting performance. Pros include its competitive price and compatibility with many truck models, but it may require more frequent greasing than other options.

4. Neapco 1-0441

The Neapco 1-0441 is a versatile U-joint that excels in both everyday driving and heavy-duty applications. Its sturdy build and greaseable design make it a reliable choice. Pros include its durability and ease of maintenance, though it may be slightly heavier than other models.

5. Rugged Ridge 11549.06

Rugged Ridge’s 11549.06 is designed for off-road enthusiasts who need a U-joint that can handle extreme conditions. Its heavy-duty construction and high load capacity make it a standout option. Pros include its toughness and reliability, but it may not be the best choice for light-duty trucks.

Installation Tips for Universal Joints

Tools and Equipment Needed

To install a U-joint, you’ll need a socket set, grease gun, press tool, and safety gear like gloves and goggles. Having the right tools on hand can make the process smoother and safer.

Step-by-Step Installation Guide

Start by securing the vehicle on a flat surface and removing the driveshaft. Use the press tool to remove the old U-joint and install the new one, ensuring it’s properly aligned. Finally, grease the U-joint and reattach the driveshaft.

Common Mistakes to Avoid

Avoid over-tightening the U-joint, as this can cause damage. Also, ensure the U-joint is properly greased and aligned to prevent premature wear. Skipping these steps can lead to poor performance and reduced lifespan.

Maintenance and Care for Universal Joints

Regular Inspection Tips

Inspect your U-joints every 10,000 miles or as recommended by your vehicle’s manufacturer. Look for signs of wear, such as rust, cracks, or excessive play, and address any issues promptly.

Lubrication Best Practices

Regular greasing is essential for maintaining U-joint performance. Use a high-quality grease and follow the manufacturer’s recommendations for frequency. Proper lubrication reduces friction and extends the component’s lifespan.

When to Replace U-Joints

Replace U-joints if you notice symptoms of failure, such as vibrations or noises, or if they show visible signs of wear. Proactive replacement can prevent more extensive drivetrain damage.

Conclusion

Choosing the right universal joint for your pickup truck is crucial for maintaining its performance, safety, and longevity. The Spicer 5-760X, Moog 371, Precision 344, Neapco 1-0441, and Rugged Ridge 11549.06 are all excellent options, each with its own strengths and features. Prioritize quality, compatibility, and durability to ensure your truck is ready for any challenge. With proper installation and maintenance, a reliable U-joint can keep your pickup running smoothly for years to come.

FAQ Section

How often should I replace my pickup truck’s U-joints?

U-joints typically last between 50,000 to 100,000 miles, but this can vary based on usage and maintenance. Regular inspections and timely replacements are key to avoiding issues.

Can I install a universal joint myself, or should I hire a professional?

While DIY installation is possible with the right tools and knowledge, hiring a professional ensures the job is done correctly and safely, especially if you’re unfamiliar with the process.

What happens if I ignore a failing U-joint?

Ignoring a failing U-joint can lead to drivetrain damage, loss of vehicle control, or even accidents. Prompt replacement is essential for safety and performance.

Are all U-joints compatible with my pickup truck?

No, U-joints must be compatible with your truck’s specific drivetrain system. Always check the manufacturer’s specifications before purchasing.

What’s the difference between greasable and non-greasable U-joints?

Comparison table for What’s the difference between greasable and non-greasable U-joints?

Greasable U-joints allow for regular lubrication, which can extend their lifespan, while non-greasable U-joints are maintenance-free but may wear out faster under heavy use.