Steel Joints

In the world of construction and engineering, steel joints serve as the backbone of structural integrity and versatility. These critical connections link steel components, ensuring stability, strength, and adaptability in everything from towering skyscrapers to intricate machinery. As industries continue to demand safer, more efficient designs, understanding the types, benefits, and challenges of steel joints becomes essential. This article explores the fundamentals of steel joints, their innovations, and their impact on modern engineering.

Historical Timeline

1880s

Early steel joints used in Eiffel Tower construction.

1920s

Welded steel joints replace riveted connections.

1960s

High-strength bolts improve joint efficiency.

2000s

Computer modeling optimizes steel joint designs.

2030s

AI-driven joint design for smart infrastructure.

Timeline infographic for Steel Joints

Introduction to Steel Joints

Steel joints are points where structural steel elements are connected to form a cohesive framework. They play a vital role in transferring loads, accommodating movement, and maintaining the integrity of the overall structure. Whether in a suspension bridge, a high-rise building, or a manufacturing plant, well-designed steel joints ensure longevity and safety, making them a cornerstone of engineering practices.

Types of Steel Joints

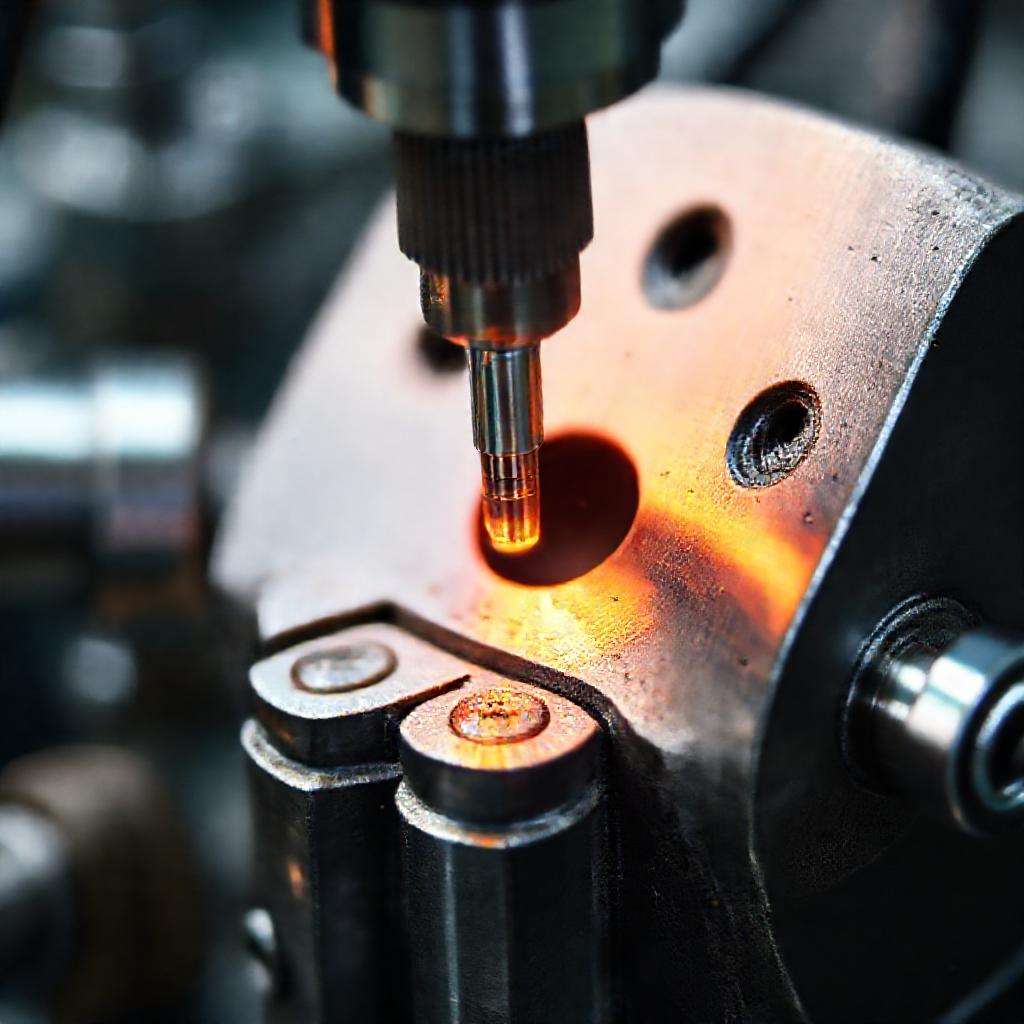

Welded Joints

Welded joints are created by melting and fusing steel pieces together using heat, often with additional filler material. This method offers exceptional strength and durability, making it ideal for permanent structures. Techniques like MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), and arc welding are commonly used, each suited to different applications based on thickness and accessibility. However, welding can introduce heat distortion and requires skilled labor to ensure quality.

Bolted Joints

Bolted joints use bolts, nuts, and washers to connect steel components with minimal heat exposure. They are favored for their ease of assembly, disassembly, and adjustment, making them perfect for modular and temporary structures. High-strength bolts, such as ASTM A325 or A490, are widely used in critical applications like bridges and industrial equipment. While cost-effective for large projects, bolted joints may need regular inspections to maintain tightness and prevent loosening over time.

Riveted Joints

Riveted joints were once the standard in steel construction, utilizing metal pins to lock components together. This method was pivotal in the early 20th century for structures like the Eiffel Tower and railroads, prized for its shear strength and resistance to vibration. Compared to modern welded or bolted joints, riveting is less common today due to higher labor costs and slower assembly. However, it’s still used in heritage restoration and specific aerospace applications where its proven reliability is crucial.

Adhesive Joints

Adhesive joints use specialized epoxy or polymer-based materials to bond steel components. They excel in distributing stress evenly, reducing weight, and resisting corrosion, particularly in complex or inaccessible areas. These joints are often paired with mechanical fasteners for added security in high-load scenarios. A key drawback is their sensitivity to temperature, humidity, and UV exposure, which can affect long-term performance.

Advantages of Steel Joints

- High strength-to-weight ratio: Steel joints provide robust connections without adding unnecessary mass to structures.

Challenges and Considerations in Steel Joint Design

Load-Bearing Capacity

Ensuring a joint can handle expected loads involves precise engineering calculations, considering factors like tension, compression, and shear forces. Safety margins and material specifications are vital to prevent failures, especially in high-stress environments like bridges or cranes.

Corrosion and Maintenance

Corrosion weakens steel joints over time, particularly in coastal or industrial areas. Preventive measures like galvanization, protective coatings, and cathodic protection are essential. Regular inspections and maintenance further extend the lifespan of these connections.

Thermal Expansion and Contraction

Steel expands in heat and contracts in cold, which can strain joints. Designers incorporate expansion joints or flexible connections to accommodate these shifts, preventing cracks or structural misalignment in projects like pipelines or long-span bridges.

Precision in Fabrication and Installation

Accuracy during fabrication and assembly is non-negotiable. Even minor misalignments can lead to stress concentrations or failures. Advanced tools like laser alignment and CNC machining help achieve the precision required for complex structures.

Innovations in Steel Joint Technology

Recent advancements are redefining steel joint capabilities. High-strength alloys and weathering steels enhance performance in extreme conditions. Smart sensors embedded in joints monitor stress levels and detect wear in real time, improving safety in critical infrastructure. Hybrid joints, combining welding with bolting, optimize strengths while mitigating weaknesses, offering tailored solutions for modern engineering challenges.

Applications of Steel Joints in Industry

Construction and Infrastructure

Steel joints are indispensable in skyscrapers, stadiums, and bridges. For example, the welded joints in the Burj Khalifa withstand wind and seismic forces, while bolted joints in modular housing enable rapid assembly.

Automotive and Aerospace

Lightweight bolted and adhesive joints are key in vehicle and aircraft frames, reducing weight without compromising safety. Riveted joints still hold value in older aircraft designs or specialized components requiring vibration resistance.

Machinery and Equipment

In heavy machinery like excavators or turbines, bolted and welded joints balance strength and adjustability. Precision joints in robotics ensure smooth, reliable movement for demanding tasks.

Conclusion

Steel joints are a cornerstone of modern engineering, blending strength, flexibility, and cost-efficiency. From traditional riveting to high-tech hybrid systems, their evolution reflects the industry’s pursuit of innovation and reliability. As technology progresses, the future of steel joints will likely harness automation, AI-driven design, and eco-friendly materials, ensuring they remain vital in shaping the infrastructure and machinery of tomorrow.

FAQs About Steel Joints

1. What is the strongest type of steel joint?

Welded joints typically offer the highest strength, as they create a seamless bond. However, bolted and riveted joints may outperform in applications requiring flexibility or disassembly. The choice depends on the load type, environmental conditions, and structural requirements.

2. How do you prevent corrosion in steel joints?

Preventive strategies include galvanization (zinc coating), epoxy or polyurethane coatings, and using stainless steel components. Cathodic protection and sealing joints from moisture further mitigate corrosion risks, while routine inspections ensure early detection of wear.

3. Can steel joints be used in earthquake-prone areas?

Yes, steel joints are ideal for seismic zones due to their ductility and ability to absorb energy. Moment-resisting welded joints and bolted connections with flexible elements are designed to sway without failing, as seen in earthquake-resistant skyscrapers and bridges.

4. What are the cost differences between welded and bolted joints?

Welded joints often have lower long-term costs and higher strength but require skilled labor and specialized equipment. Bolted joints are more expensive upfront due to hardware costs but save time in assembly and allow for easier repairs, making them cost-effective in dynamic projects.

5. Are there environmentally friendly steel joint options?

Steel is inherently recyclable, reducing waste in joint construction. Innovations like low-VOC adhesives, energy-efficient welding techniques, and rust-resistant coatings further enhance sustainability. Prefabricated bolted joints also minimize on-site resource consumption.