In precision engineering and manufacturing, the reliability of fasteners is non-negotiable. Among the most trusted fasteners in high-stress applications are socket head cap screws, known for their strength and versatility. However, their effectiveness hinges on one critical factor: proper torque application. Applying the correct torque ensures optimal clamping force, prevents loosening, and safeguards against premature failure. This is where a socket head cap screw torque chart becomes indispensable—a tool that provides precise torque values tailored to specific screw sizes, materials, and conditions. Whether you’re an engineer, technician, or hobbyist, understanding and using these charts correctly can mean the difference between a secure assembly and a catastrophic failure.

Introduction to Socket Head Cap Screw Torque Charts

Socket head cap screws (SHCS) are renowned for their high clamping force, resistance to vibration, and ability to withstand extreme loads. Their cylindrical head with a hexagonal socket recess makes them ideal for applications where space is limited, yet strength is paramount. Torque charts serve as a reference guide, listing the recommended torque values for various screw specifications. These values account for factors like material hardness, thread pitch, and lubrication, ensuring that each screw is tightened to the exact force required for its intended application.

Understanding Socket Head Cap Screws

What Are Socket Head Cap Screws?

Socket head cap screws feature a cylindrical head with a recessed hexagon socket, designed to be driven with an Allen key. The screw’s design minimizes head height while maximizing thread engagement, making them suitable for tight spaces. They are commonly made from materials like stainless steel, alloy steel, or titanium, each offering distinct advantages in terms of strength, corrosion resistance, and weight. Surface treatments such as zinc plating or passivation further enhance durability depending on the environment.

Applications of Socket Head Cap Screws

SHCS are ubiquitous in industries where precision and reliability are critical. In aerospace, they secure critical components like engine mounts and landing gear. The automotive sector relies on them for high-performance parts, while machinery and robotics benefit from their ability to withstand repetitive stress. Their compact design and high load-bearing capacity make them indispensable in applications where traditional hex head bolts would be impractical.

The Importance of Proper Torque in Fastening

What Is Torque and Why Does It Matter?

Torque is the rotational force applied to a screw to achieve the necessary clamping force. Proper torque ensures that the screw is tightened enough to prevent loosening but not so much that it causes damage. The correct torque value translates into uniform stress distribution, reducing the risk of material fatigue or thread failure over time.

Risks of Incorrect Torque Application

Under-tightening can lead to vibration-induced loosening, while over-tightening may cause the screw to strip or the material to deform. Both scenarios compromise the integrity of the assembly, potentially leading to equipment failure or safety hazards. For example, in aerospace applications, even a slight deviation from recommended torque values could have catastrophic consequences.

Factors Affecting Torque Requirements

The required torque depends on several variables, including the screw’s material grade, thread pitch, and whether lubrication is applied. Harder materials like high-strength steel require higher torque values compared to softer metals. Lubrication reduces friction, allowing for more accurate torque application and potentially lowering the required force. Environmental factors such as temperature and humidity can also influence the performance of fasteners.

How to Use a Socket Head Cap Screw Torque Chart

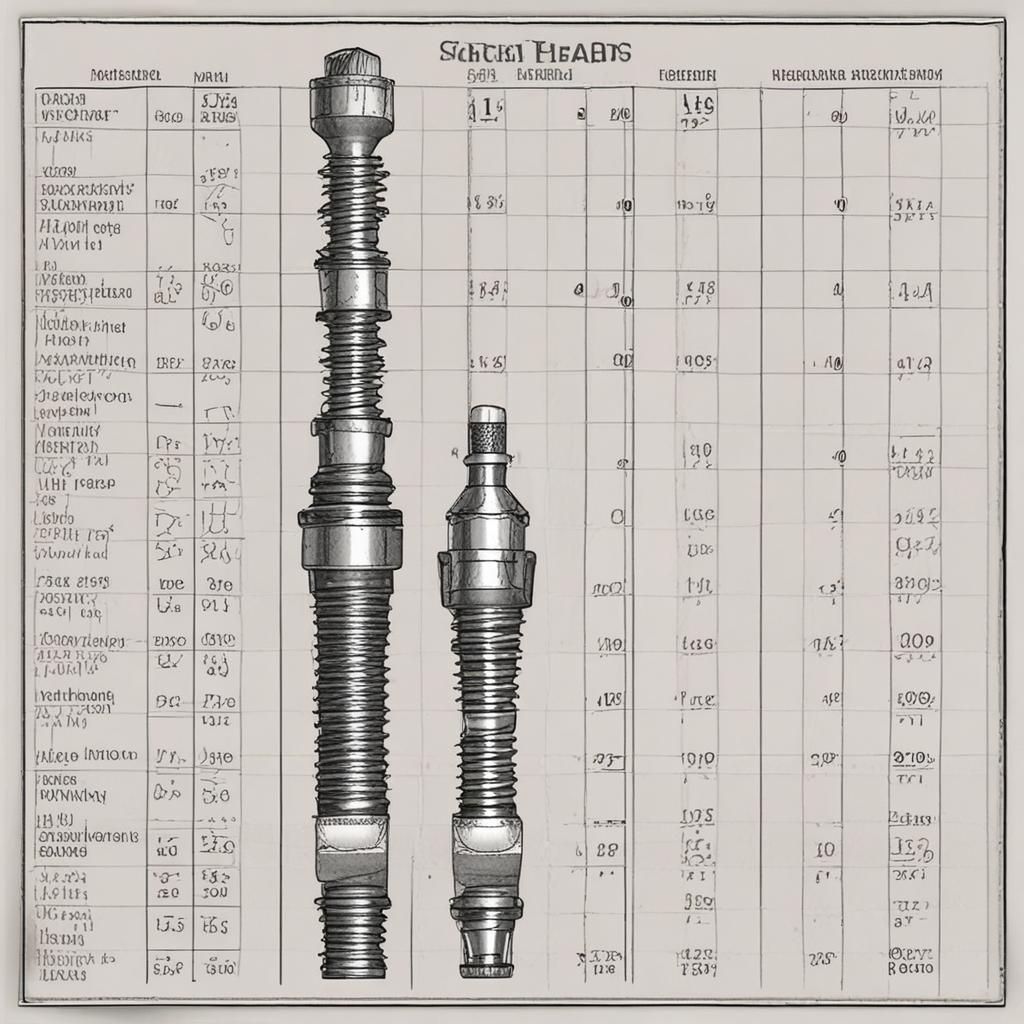

Components of a Torque Chart

A typical torque chart includes columns for screw size, thread pitch, material grade, and corresponding torque values in both metric (Newton-meters) and imperial (foot-pounds) units. Some charts also specify whether the values are for dry or lubricated conditions.

Reading and Interpreting the Chart

To use a torque chart, first identify the screw’s size and material grade. Locate the corresponding row in the chart, then match the thread pitch and lubrication condition. The chart will provide the exact torque value needed, ensuring accurate tightening.

Tips for Accurate Torque Application

Always use a calibrated torque wrench and follow the manufacturer’s guidelines for lubrication. Apply torque in a controlled manner, avoiding sudden jerks. Additionally, ensure that the screw and mating threads are clean and free of debris to prevent inconsistent tightening.

Socket Head Cap Screw Torque Chart Examples

Metric Socket Head Cap Screw Torque Chart

For example, a metric M6 x 1 stainless steel socket head cap screw may require a torque of 12 Nm (dry) or 9 Nm (lubricated). Larger screws, such as M10 x 1.5, might need 40 Nm (dry) or 30 Nm (lubricated). These values are approximate and should be verified with a specific torque chart for your application.

Imperial Socket Head Cap Screw Torque Chart

Imperial screws, such as a 1/4-20 UNC socket head cap screw, may require 10-12 ft-lbs (dry) or 8-10 ft-lbs (lubricated). Larger sizes like 1/2-13 UNC could need 40-50 ft-lbs (dry) or 30-40 ft-lbs (lubricated). Always cross-reference with a reliable torque chart to ensure accuracy.

Comparing Different Material Grades

Torque values vary significantly between materials. For instance, a titanium screw may require less torque than a steel screw of the same size due to its lower Young’s modulus. Always consult a torque chart that specifies the material grade for precise values.

Tools for Applying Correct Torque

Types of Torque Wrenches

Manual torque wrenches are the most common, with click-type or beam-style designs. Digital torque wrenches offer precise measurements and memory functions, ideal for high-precision applications. Each type has its advantages, and the choice depends on the required accuracy and budget.

Calibration and Maintenance of Torque Tools

Regular calibration ensures that torque wrenches remain accurate. Most manufacturers recommend calibration every 6 to 12 months, depending on usage frequency. Proper storage and handling also extend the lifespan of these tools.

Common Mistakes to Avoid When Using Torque Charts

Mistakes such as ignoring lubrication, misreading screw specifications, or failing to account for environmental conditions can lead to incorrect torque application. Always double-check the chart and ensure that all conditions match those specified in the reference.

Conclusion

Proper torque application is the backbone of reliable fastening, and socket head cap screw torque charts are the key to achieving it. By understanding the factors that influence torque values and using the right tools and techniques, you can ensure the safety and longevity of your assemblies. Always refer to trusted sources for torque charts and prioritize accuracy in your tightening process.

FAQs About Socket Head Cap Screw Torque Charts

-

What is the difference between dry and lubricated torque values? Lubrication reduces friction between threads, allowing for more accurate torque application and often lowering the required force. Dry torque values are higher to compensate for increased friction.

Can I use the same torque chart for different screw materials? No, torque values vary based on material properties. Always use a chart that specifies the material grade of your screws.

How often should I calibrate my torque wrench? Calibration is recommended every 6 to 12 months, or more frequently for heavy-duty applications.

What happens if I exceed the recommended torque value? Over-tightening can strip threads, damage the screw head, or deform the material, compromising the assembly’s integrity.

Where can I find a reliable torque chart for my specific application? Manufacturer guidelines, engineering handbooks, and industry standards such as ISO or ANSI are trusted sources for accurate torque charts.