Craftsman Socket Size Chart

For craftsmen and DIY enthusiasts, having the right tools is essential, and knowing the correct socket sizes can make all the difference between a job well done and a frustrating struggle. Socket size charts serve as invaluable references, helping you quickly identify the right fit for bolts, nuts, and fasteners. In this article, we’ll explore how to use Craftsman socket size charts effectively, ensuring you work with precision and confidence.

Understanding Socket Sizes and Measurements

What Are Socket Sizes?

Socket sizes refer to the dimensions of the openings in socket wrenches that fit over bolts and nuts. These sizes are crucial for tightening or loosening fasteners without damaging them. Two primary measurement systems are used: SAE (Society of Automotive Engineers), which uses inches, and metric, which uses millimeters. Many modern tools, like Craftsman sets, include both systems to accommodate a wide range of applications.

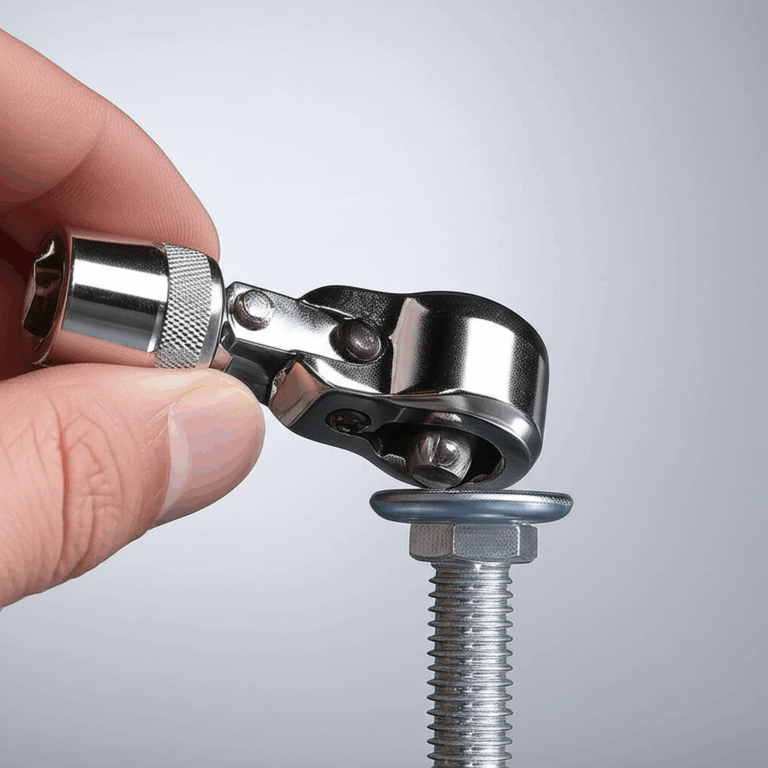

How Are Socket Sizes Measured?

Socket sizes are typically measured by the width across the flats (WAF) of the fastener they’re designed to fit. This measurement ensures compatibility with the specific bolt or nut you’re working on. Tools like calipers or a standard ruler can help determine the WAF. For metric fasteners, measurements are in millimeters, while SAE sizes are in fractions of an inch.

Craftsman Socket Size Chart: Overview and Uses

What Is a Craftsman Socket Size Chart?

A Craftsman socket size chart is a reference tool that lists standard SAE and metric socket sizes, often including drive sizes (like 1/4″, 3/8″, or 1/2″). It helps users match the right socket to the job, reducing errors and tool wear. The chart is especially useful for Craftsman socket sets, which are designed for durability and precision.

Types of Craftsman Socket Size Charts

Printable charts are convenient for workshops without internet access, offering a physical reference you can hang or keep in a tool box. Online charts are interactive and often include additional resources like conversion tables or application guides. Mobile apps, another type, provide portability but require a compatible device. Each type has trade-offs—choose based on your workflow and preferences.

How to Use a Craftsman Socket Size Chart

Using a Craftsman socket size chart is straightforward. Measure the WAF of the fastener, match it to the chart’s size column, and select the corresponding socket. For example, if you’re changing a car tire and encounter a 14mm lug nut, the chart confirms you need a 14mm socket. Always cross-check with the fastener’s head to ensure a snug fit and avoid rounding edges.

Craftsman Socket Size Chart: SAE and Metric Sizes

SAE Socket Size Chart

- 1/4″ Drive: 5/32″, 3/16″, 1/4″, 5/16″, 3/8″

- 3/8″ Drive: 7/16″, 1/2″, 9/16″, 5/8″, 11/16″

- 1/2″ Drive: 3/4″, 13/16″, 7/8″, 15/16″, 1″

SAE sizes are commonly used in automotive and machinery work in the U.S., making them ideal for classic cars or older equipment.

Metric Socket Size Chart

- 1/4″ Drive: 4mm, 5mm, 6mm, 7mm, 8mm

- 3/8″ Drive: 10mm, 12mm, 13mm, 14mm, 16mm

- 1/2″ Drive: 17mm, 19mm, 21mm, 24mm, 30mm

Metric sizes dominate modern automotive and industrial applications, particularly in newer vehicles and machinery designed outside the U.S. Having a dual-system chart ensures you’re prepared for any task.

Tips and Best Practices for Using a Craftsman Socket Size Chart

Common Mistakes to Avoid

One common error is misreading measurements due to confusion between SAE and metric systems. Always verify the fastener’s size using a ruler or caliper before selecting a socket. Another pitfall is using a socket that’s too large or too small, which can strip the fastener or damage the socket. Double-check the WAF and drive size to avoid these issues.

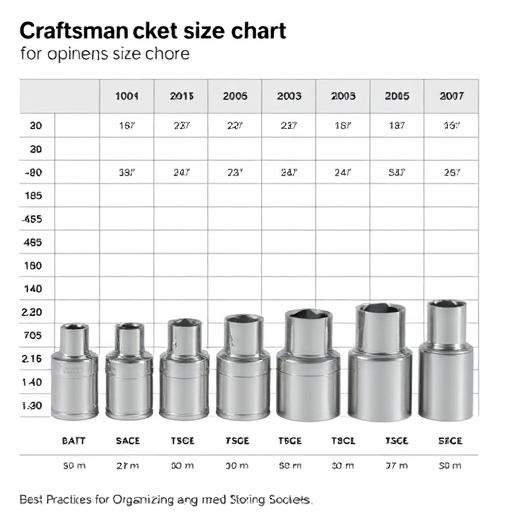

Best Practices for Organizing and Storing Sockets

Proper organization saves time and prevents damage. Sort sockets by drive size and store them in labeled trays or wall-mounted racks. Magnetic storage solutions keep frequently used sizes accessible, while airtight containers protect against rust. Regularly clean sockets and inspect for wear to maintain their effectiveness.

Conclusion

A Craftsman socket size chart is more than a handy tool—it’s a cornerstone of efficient, error-free work. Whether you’re tackling a home project or professional repair, understanding SAE and metric sizes ensures you’re always prepared. With the right chart and organization strategies, you’ll streamline your workflow and extend the life of your tools. Keep this guide close at hand and watch your productivity soar.

Frequently Asked Questions (FAQs)

What Is the Most Common Socket Size Used by Craftsmen?

The most frequently used socket size is 3/8″ drive, as it balances versatility and strength for a wide range of tasks.

How Do I Read a Craftsman Socket Size Chart?

Locate the column that matches your fastener’s size (SAE or metric) and find the corresponding drive size. This pairing ensures the socket fits both the fastener and your wrench.

What Is the Difference Between SAE and Metric Socket Sizes?

Comparison table for What Is the Difference Between SAE and Metric Socket Sizes?

SAE sizes are measured in fractions of an inch and are common in the U.S., while metric sizes use millimeters and are widely adopted globally. The key difference lies in the units and the typical applications they serve.

Can I Use a Craftsman Socket Size Chart for Other Brands of Sockets?

Yes! Craftsman charts align with universal socket size standards, making them applicable to most SAE and metric sockets, regardless of brand.

How Often Should I Update My Craftsman Socket Size Chart?

Update it when you add new sockets to your set or if you encounter non-standard sizes in your work. Newer tools and fasteners occasionally introduce less common dimensions.