Universal Joint Socket 1 2

Universal joint sockets, particularly the 1/2 inch size, are indispensable components in various mechanical and automotive applications. These versatile tools play a crucial role in transmitting power and ensuring smooth operation in machinery and vehicles. Understanding their function, types, and maintenance can significantly enhance the performance and longevity of your equipment. This article delves into the world of universal joint sockets 1/2, providing you with comprehensive insights and practical advice.

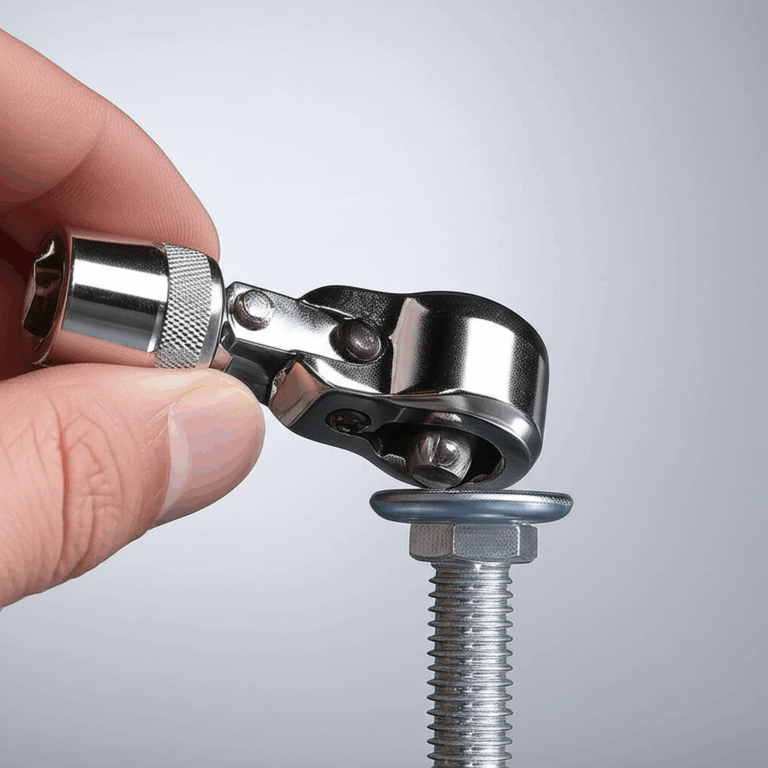

Step-by-Step Process

Select Tool

Choose socket set

Measure Shaft

Determine size

Align Joint

Position socket

Tighten Nut

Secure joint

Test Joint

Verify movement

Process infographic for Universal Joint Socket 1 2

What is a Universal Joint Socket 1/2?

A universal joint socket 1/2 is a mechanical device designed to connect and transmit rotational power between two shafts that are not in a straight line. It consists of a central cross with four arms, each equipped with a bearing, allowing for flexibility and movement. Common sizes for universal joint sockets are measured in fractions of an inch, with 1/2 inch being a widely used standard.

Key Components and Structure

The primary components of a universal joint socket 1/2 include:

- Yokes: The arms that connect to the shafts.

Common Sizes and Specifications

The 1/2 inch universal joint socket is a standard size, suitable for a wide range of applications. It is typically used in medium to heavy-duty machinery and automotive systems. Specifications may vary, but common features include:

- Material: Steel or alloy for durability.

Functions and Applications of Universal Joint Socket 1/2

Automotive Industry

In the automotive industry, universal joint sockets 1/2 are essential for:

- Transmission Systems: Connecting the transmission to the drive shaft.

Industrial Applications

Industrial machinery and equipment often rely on universal joint sockets 1/2 for:

- Machinery and Equipment: Power transmission in conveyor systems, pumps, and other mechanical devices.

DIY and Home Projects

For DIY enthusiasts and home projects, universal joint sockets 1/2 are useful for:

- Repairs and Maintenance: Replacing worn-out joints in various mechanical devices.

Types of Universal Joint Sockets 1/2

Straight Joints

Straight joints are the simplest form of universal joint sockets. They consist of a single cross and yokes, allowing for basic angular movement. They are commonly used in applications where the angle between the shafts is relatively small.

Cross Joints

Cross joints feature a more complex design with a central cross and multiple bearings, providing greater flexibility and range of motion. They are suitable for applications where the angle between the shafts is more significant.

Constant Velocity (CV) Joints

CV joints are advanced universal joint sockets designed to maintain a constant velocity during rotation, even at significant angles. They are commonly used in front-wheel-drive vehicles and other high-performance applications.

How to Choose the Right Universal Joint Socket 1/2

Material Considerations

When selecting a universal joint socket 1/2, consider the material:

- Steel: Strong and durable, suitable for heavy-duty applications.

Size and Fit

Ensure the correct size and fit by:

- Measuring the shaft diameter and angle of operation.

Durability and Lifespan

Factors affecting the longevity of a universal joint socket 1/2 include:

- Material quality.

Installation and Maintenance of Universal Joint Socket 1/2

Pre-Installation Checklist

Before installing a universal joint socket 1/2, ensure you have:

- The necessary tools, such as wrenches and sockets.

Step-by-Step Installation Guide

- Remove the old joint by loosening the bolts and sliding it off the shafts.

- Clean the shafts and inspect them for any damage.

- Slide the new joint onto the shafts and secure it with the bolts.

- Apply grease to the bearings to ensure smooth operation.

Maintenance Tips

To keep your universal joint socket 1/2 in optimal condition:

- Perform regular checks for wear and tear.

Common Issues and Troubleshooting

Wear and Tear

Signs of wear and tear include:

- Increased noise during operation.

Loose or Noisy Joints

Causes and solutions for loose or noisy joints include:

- Tightening loose bolts.

Performance Issues

To diagnose and fix performance issues:

- Check for proper alignment of the shafts.

Benefits of Using Universal Joint Socket 1/2

Versatility

Universal joint sockets 1/2 are highly adaptable, suitable for various applications in automotive, industrial, and DIY projects.

Cost-Effectiveness

They are affordable and durable, providing a cost-effective solution for power transmission and mechanical systems.

Performance Enhancement

Using a high-quality universal joint socket 1/2 can improve the efficiency and reliability of your machinery and vehicles.

Conclusion

Understanding the universal joint socket 1/2, its functions, and proper maintenance can significantly enhance the performance and longevity of your mechanical systems. Whether you are a professional mechanic or a DIY enthusiast, this versatile tool is essential for a wide range of applications. By following the guidelines and tips provided, you can ensure that your universal joint socket 1/2 operates smoothly and efficiently. Explore further to discover more about the specific needs of your projects and applications.

FAQ

What is the main function of a universal joint socket 1/2?

The main function of a universal joint socket 1/2 is to connect and transmit rotational power between two shafts that are not in a straight line, ensuring smooth and efficient operation in various mechanical and automotive systems.

How do I know if I need to replace my universal joint socket 1/2?

You may need to replace your universal joint socket 1/2 if you notice increased noise, loose or sloppy movement, or visible damage to the joint or shafts.

Can I install a universal joint socket 1/2 myself?

Yes, you can install a universal joint socket 1/2 yourself with the right tools and safety precautions. However, it is important to follow the manufacturer’s instructions and ensure proper alignment and lubrication.

What materials are universal joint sockets 1/2 typically made of?

Universal joint sockets 1/2 are typically made of steel or alloy. Steel is strong and durable, while alloy is lightweight and corrosion-resistant.

How often should I maintain my universal joint socket 1/2?

Maintain your universal joint socket 1/2 by performing regular checks for wear and tear and lubricating the bearings as recommended by the manufacturer. A general maintenance schedule might include monthly inspections and quarterly lubrication, depending on the application and operating conditions.