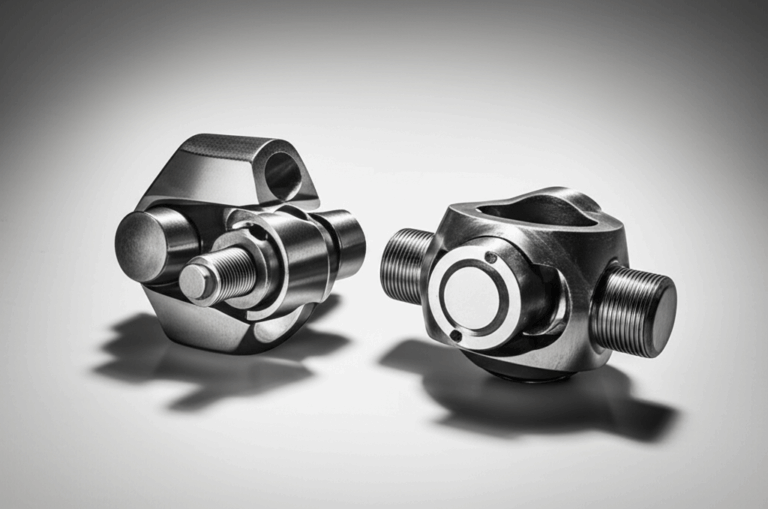

Universal Joint Socket 12 Point

When it comes to automotive and industrial maintenance, the right tools can make all the difference. One such essential tool is the universal joint socket, particularly the 12-point design. Known for its versatility, precision, and durability, the 12-point universal joint socket is a must-have for professionals and DIY enthusiasts alike. In this article, we will delve into the details of what makes the 12-point universal joint socket a top choice and how to use it effectively.

Step-by-Step Process

Select Joint Size

Choose the correct size for your application.

Inspect Socket

Check for wear or damage before use.

Apply Lubricant

Lubricate the joint for smooth operation.

Install Joint

Secure the joint in the drive shaft.

Test Operation

Run a test to ensure proper function.

Process infographic for Universal Joint Socket 12 Point

What is a Universal Joint Socket?

A universal joint socket is a specialized tool designed to fit and turn fasteners in tight or hard-to-reach areas. Commonly used in automotive and industrial settings, it is essential for tasks involving engine and transmission work, as well as machinery maintenance. Unlike standard sockets, a universal joint socket can pivot at an angle, allowing for greater flexibility and access to fasteners in confined spaces.

The 12-Point Design: An Overview

The 12-point configuration of a universal joint socket provides several advantages over 6-point and 8-point designs. With 12 contact points, the socket can engage more surfaces of the fastener, ensuring a secure grip and reducing the risk of rounding off the fastener head. This design is particularly useful for working with hex bolts and nuts, as it allows for more precise and efficient torque application.

Key Features of a Universal Joint Socket 12 Point

Material and Durability

High-quality materials are crucial for the performance and longevity of a universal joint socket. Chrome vanadium steel is a popular choice due to its strength, resistance to corrosion, and ability to withstand high torque. Using such materials ensures that the socket remains durable and reliable, even in demanding conditions.

Size and Fit

Universal joint sockets are available in a range of sizes to fit various fasteners. Whether you need to work with metric or imperial measurements, there is a 12-point socket that will meet your needs. The precision fit ensures that the socket engages the fastener securely, minimizing the risk of slippage and damage.

Design and Functionality

The 12-point design enhances grip and distributes torque more evenly across the fastener, reducing wear and tear. This feature is particularly beneficial when working with high-torque applications, as it helps prevent rounding off the fastener head and extends the life of your tools.

How to Use a Universal Joint Socket 12 Point

Preparation and Safety

Before using a universal joint socket, it is essential to prioritize safety. Wear appropriate protective gear, such as gloves and safety glasses, to protect yourself from potential hazards. Prepare your work area by ensuring it is clean and well-lit, and have all necessary tools and equipment ready.

Installation and Removal

To install or remove a fastener using a 12-point universal joint socket, follow these steps:

- Identify the correct size socket for the fastener.

Tips for optimal performance include using a lubricant on the fastener to reduce friction and checking the socket for any signs of wear or damage before use.

Maintenance and Care

Proper maintenance is crucial for the longevity and performance of your universal joint socket. After each use, clean the socket with a degreaser and dry it thoroughly. Store the socket in a dry, clean place to prevent rust and corrosion. Regularly inspect the socket for signs of wear, such as cracks or deformation, and replace it if necessary.

Benefits of Using a Universal Joint Socket 12 Point

Versatility

The 12-point universal joint socket is compatible with a wide range of tools and fasteners, making it a versatile addition to any toolkit. Whether you are working on a car engine or maintaining industrial machinery, this socket can handle a variety of tasks.

Efficiency

Thanks to its 12-point design, this socket is faster and easier to use compared to other types. The enhanced grip and torque distribution allow for quick and efficient installation and removal of fasteners, saving you time and effort.

Durability

High-quality materials and robust construction ensure that the 12-point universal joint socket is long-lasting and resistant to wear. With proper care and maintenance, this tool can serve you well for many years.

Precision

The 12-point design provides accurate and reliable performance, making it ideal for precision work. The increased number of contact points ensures a secure fit and reduces the risk of damaging the fastener.

Common Applications of Universal Joint Sockets 12 Point

Automotive Repair

In automotive repair, the 12-point universal joint socket is essential for tasks such as engine and transmission work. It is particularly useful for reaching fasteners in tight engine compartments and other confined spaces.

Industrial Maintenance

For industrial maintenance, this socket is a valuable tool for repairing and maintaining machinery and equipment. Its ability to pivot at an angle makes it ideal for accessing fasteners in hard-to-reach areas, ensuring that maintenance tasks are completed efficiently and effectively.

DIY Projects

Home improvement and DIY enthusiasts can also benefit from using a 12-point universal joint socket. Whether you are working on a home repair project or building furniture, this versatile tool can handle a variety of tasks and make your work easier and more precise.

Choosing the Right Universal Joint Socket 12 Point

Factors to Consider

When selecting a 12-point universal joint socket, consider the following factors:

- Size and Type of Fasteners: Ensure the socket is the correct size for the fasteners you will be working with.

Top Brands and Models

Based on user reviews and expert opinions, some top brands and models of 12-point universal joint sockets include:

- Matco Tools

These brands are known for their high-quality materials, durability, and performance, making them reliable choices for both professionals and DIY enthusiasts.

Troubleshooting Common Issues

Worn or Damaged Sockets

Signs of wear and damage include cracks, deformation, and rust. If you notice any of these issues, it is time to replace the socket to ensure safe and effective use.

Stuck Fasteners

When dealing with stuck fasteners, try the following techniques:

- Apply a penetrating oil to the fastener to loosen it.

Safety Concerns

Common mistakes to avoid include using the wrong size socket, applying too much torque, and not wearing appropriate safety gear. Always follow proper safety protocols to prevent accidents and injuries.

Conclusion

In conclusion, the 12-point universal joint socket is a versatile, efficient, and durable tool that can significantly enhance your automotive and industrial maintenance tasks. Its 12-point design provides a secure grip and even torque distribution, making it ideal for a wide range of applications. By choosing the right socket, using it correctly, and maintaining it properly, you can ensure optimal performance and longevity. Try a 12-point universal joint socket today and experience the difference it can make in your work.

FAQ Section

What is the difference between a 12-point and a 6-point socket?

The main difference between a 12-point and a 6-point socket lies in the number of contact points. A 12-point socket has more contact points, which allows for a tighter fit and reduces the risk of rounding off the fastener head. A 6-point socket, on the other hand, is better suited for high-torque applications where a more robust grip is needed.

Can a universal joint socket 12 point be used for all types of fasteners?

While a 12-point universal joint socket is highly versatile, it is not suitable for all types of fasteners. It is best used with hex bolts and nuts. For other types of fasteners, such as Torx or Allen bolts, you will need a socket designed for that specific type of fastener.

How often should I replace my universal joint socket 12 point?

The lifespan of a universal joint socket 12 point depends on factors such as frequency of use, type of work, and maintenance. Regularly inspect the socket for signs of wear and damage, and replace it if you notice any issues. Generally, a well-maintained socket can last for many years.

Are universal joint sockets 12 point more expensive than other types?

The cost of a 12-point universal joint socket can vary depending on the brand, quality, and size. While high-quality 12-point sockets may be more expensive than their 6-point counterparts, they offer better performance and durability, making them a worthwhile investment.

What safety gear should I use when working with a universal joint socket 12 point?

When working with a universal joint socket 12 point, it is essential to use appropriate safety gear, including:

- Safety glasses to protect your eyes from debris

Using these safety measures will help ensure a safe and efficient work environment.