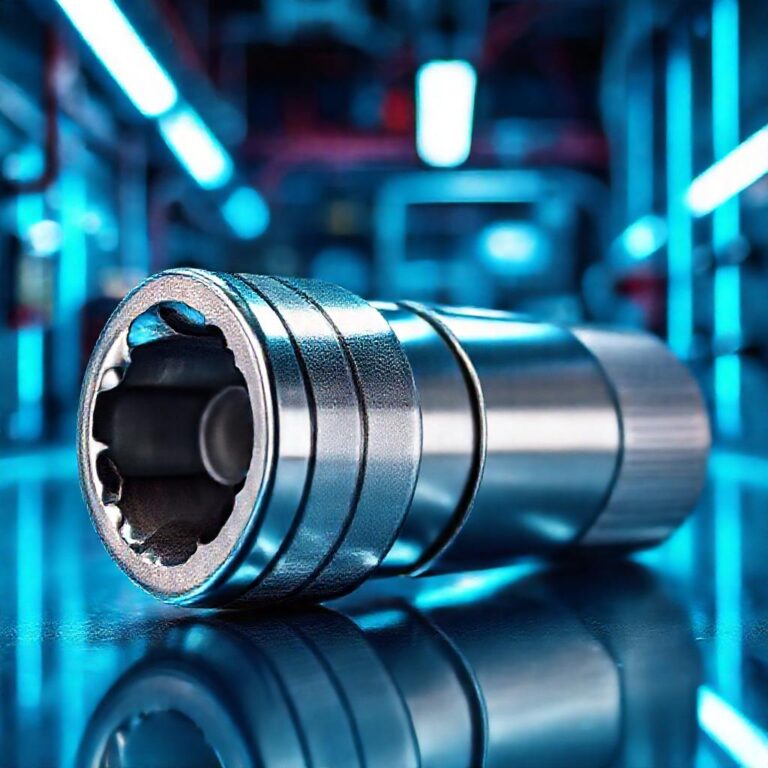

Spring Loaded Universal Joint Socket

Spring loaded universal joint sockets are essential components in various mechanical systems, playing a crucial role in ensuring smooth and efficient power transmission. These innovative devices are designed to handle misalignment and absorb shock, making them indispensable in industries ranging from automotive to manufacturing. In this article, we will explore the functionality, applications, benefits, and maintenance of spring loaded universal joint sockets, helping you understand why they are a preferred choice for many professionals.

Introduction to Spring Loaded Universal Joint Sockets

Universal joint sockets, or U-joints, are mechanical devices used to connect two shafts that are not in a straight line. They are vital in transmitting rotational motion and power between these shafts, even when there is significant angular misalignment. Spring loaded universal joint sockets take this functionality a step further by incorporating a spring mechanism that enhances their ability to handle misalignment and reduce wear. This makes them particularly useful in applications where precision and durability are paramount.

What are Spring Loaded Universal Joint Sockets?

Definition and Functionality

Spring loaded universal joint sockets are U-joints that include a spring-loaded mechanism. This mechanism allows the socket to flex and adjust to the misalignment between the connected shafts, providing a smoother and more reliable connection. The spring loading helps to maintain consistent contact between the socket and the yoke, reducing the risk of wear and tear on both components. This design is especially beneficial in high-vibration environments and applications where angular misalignment is common.

Types of Spring Loaded Universal Joint Sockets

Spring loaded universal joint sockets come in various sizes, materials, and designs to suit different applications. Common types include:

- Size Variations: Ranging from small, compact sockets for precise applications to larger, robust sockets for heavy-duty use.

Understanding these variations can help you choose the right spring loaded universal joint socket for your needs, ensuring optimal performance and longevity.

Applications of Spring Loaded Universal Joint Sockets

Industrial Applications

Spring loaded universal joint sockets are widely used in various industrial settings, including manufacturing, automotive, and construction. In manufacturing, they are essential in machinery and equipment that require precise and reliable power transmission, such as conveyor systems and robotic arms. In construction, they are used in heavy machinery like excavators and cranes to handle the harsh conditions and high loads common in these environments.

Automotive Applications

In the automotive industry, spring loaded universal joint sockets play a critical role in the drivetrain. They are used to connect the transmission to the driveshaft and the driveshaft to the differential, ensuring smooth and efficient power transfer from the engine to the wheels. These sockets help to reduce vibration, improve performance, and increase the lifespan of drivetrain components. They are particularly beneficial in off-road and high-performance vehicles where angular misalignment and shock absorption are crucial.

Benefits and Advantages

Enhanced Performance

Spring loaded universal joint sockets offer several performance benefits. They reduce vibration, which can improve the overall efficiency and smoothness of mechanical systems. The spring loading mechanism also increases torque capacity, allowing the socket to handle higher loads without compromising performance. This makes them ideal for applications where high torque and smooth operation are essential.

Key Features

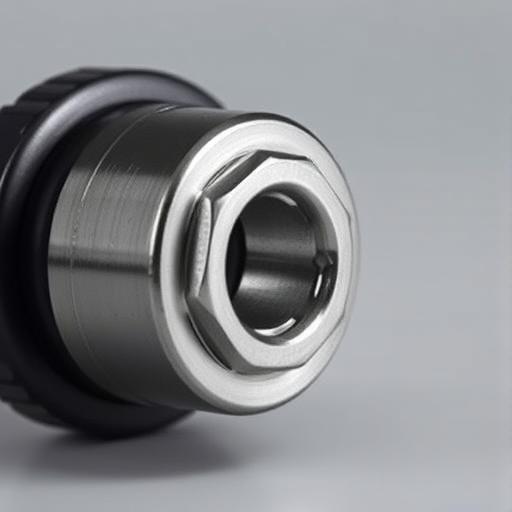

Spring-Loaded Mechanism

Ensures smooth and consistent engagement

Available

Universal Joint Compatibility

Fits multiple joint types and sizes

Available

High-Durability Socket

Resistant to wear and tear

Available

Quick-Release Design

Easy installation and removal

Available

Precision Machining

Guaranteed fit and finish

Available

Feature overview for Spring Loaded Universal Joint Socket

Durability and Maintenance

One of the significant advantages of spring loaded universal joint sockets is their durability. The spring loading mechanism helps to distribute stress more evenly, reducing wear and tear on the socket and connected components. This can extend the lifespan of the socket and reduce the need for frequent maintenance. Proper installation and regular inspection can further enhance their durability and reliability.

Installation and Maintenance Considerations

Choosing the Right Socket

Selecting the appropriate spring loaded universal joint socket for your application involves several considerations. First, determine the size of the socket based on the shaft diameter and the required torque capacity. Next, consider the material of the socket, ensuring it is suitable for the operating environment. Finally, check for compatibility with the existing components and consult the manufacturer’s specifications to ensure a proper fit.

Installation Procedures

Proper installation is crucial for the performance and longevity of spring loaded universal joint sockets. Follow these steps:

- Prepare the Components: Clean and inspect the shafts and yokes to ensure they are free from debris and damage.

- Align the Components: Ensure that the shafts are aligned according to the manufacturer’s specifications to prevent misalignment.

- Install the Socket: Carefully place the socket on the shaft and secure it using the appropriate fasteners. Follow the torque specifications to ensure a secure fit.

- Check for Proper Alignment: After installation, double-check the alignment and torque to ensure everything is correctly positioned.

- Test the System: Run a test to ensure the socket is functioning properly and there are no issues with vibration or performance.

Following these steps can help you achieve a successful installation and avoid common problems.

Challenges and Limitations

Common Issues and Solutions

While spring loaded universal joint sockets are highly reliable, they can encounter issues such as misalignment, overload, and wear. Misalignment can be addressed by ensuring proper installation and regular inspection. Overload can be prevented by selecting a socket with the appropriate torque capacity and avoiding excessive loads. Wear can be minimized through proper lubrication and regular maintenance. If issues arise, consult the manufacturer’s troubleshooting guide or seek professional assistance to ensure the problem is resolved correctly.

Conclusion

Spring loaded universal joint sockets are essential components in various mechanical systems, offering enhanced performance, durability, and reliability. Their ability to handle misalignment and absorb shock makes them ideal for a wide range of industrial and automotive applications. By understanding their functionality, applications, and maintenance requirements, you can ensure that your mechanical systems operate smoothly and efficiently. As technology continues to advance, the importance and versatility of spring loaded universal joint sockets are likely to grow, making them a valuable asset in many industries.

FAQ

-

What is the primary advantage of using spring loaded universal joint sockets?

The primary advantage is their ability to absorb misalignment and provide smooth power transmission, reducing wear and tear on connected components.

-

How do I determine the correct size of a spring loaded universal joint socket for my application?

Determining the correct size involves considering the shaft size, torque requirements, and angular misalignment of your application. Consulting with a supplier or using selection guides can be helpful.

-

Can spring loaded universal joint sockets be used in high-speed applications?

Yes, they can be used in high-speed applications, but it’s crucial to select a socket designed for high-speed use and to follow the manufacturer’s recommendations for maximum speed and torque.

-

What maintenance is required for spring loaded universal joint sockets?

Regular maintenance includes inspecting for wear, ensuring proper lubrication, and checking for misalignment. Following the manufacturer’s maintenance schedule is recommended.

-

Are spring loaded universal joint sockets suitable for use in harsh environments?

Yes, many spring loaded universal joint sockets are designed for use in harsh environments, including those with high temperatures, dust, or corrosive substances. Selecting a socket with appropriate materials and coatings is essential.