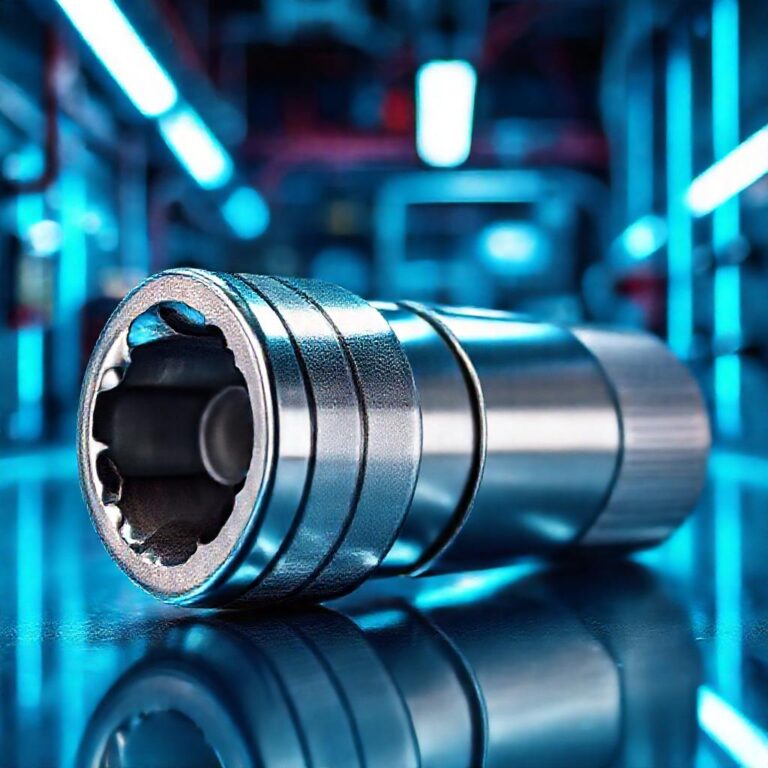

U Joint Impact Socket

When it comes to automotive repairs and maintenance, having the right tools can make all the difference. One such tool that has gained significant popularity among mechanics and DIY enthusiasts is the u joint impact socket. This specialized socket is designed to tackle tight and hard-to-reach fasteners, making it an indispensable addition to any toolkit. In this ultimate guide, we’ll explore what a u joint impact socket is, its key benefits, common applications, and how to choose the right one for your needs.

Introduction to U Joint Impact Sockets

A u joint impact socket, also known as a flex-head impact socket, is a specialized tool designed to access and loosen or tighten fasteners in tight or obstructed areas. Unlike standard impact sockets, which require a straight-line approach, a u joint impact socket features a flexible universal joint (u-joint) at the end, allowing it to swivel and reach fasteners at angles. This unique design makes it particularly useful in automotive repairs, where direct access to bolts and nuts is often limited by other components. Its growing popularity among professionals and DIYers is a testament to its versatility and efficiency.

What Is a U Joint Impact Socket?

A u joint impact socket is a standard socket with a built-in universal joint (u-joint) that allows it to swivel and articulate at angles. This flexibility enables mechanics to reach fasteners in tight spaces without the need to remove surrounding parts, making it a game-changer in automotive and industrial applications.

Anatomy of a U Joint Impact Socket

The u joint impact socket consists of several key components:

- Drive Size: Common drive sizes include 1/4″, 3/8″, and 1/2″. The drive size should match the drive on your impact wrench or ratchet.

How It Differs from Standard and Flex-Head Sockets

While standard impact sockets are essential for most applications, they have limitations in tight spaces. Flex-head sockets, which have a fixed angle, offer some flexibility but are not as versatile as u joint impact sockets. The key differences include:

- Universal Movement: U joint impact sockets can swivel up to 30°, providing more flexibility than flex-head sockets.

Key Benefits of Using a U Joint Impact Socket

Mechanics and DIY enthusiasts choose u joint impact sockets for several reasons, each contributing to their overall efficiency and effectiveness.

Enhanced Access in Tight Spaces

One of the primary advantages of u joint impact sockets is their ability to access recessed or obstructed fasteners. This is particularly useful in engine bays, suspension systems, and behind brackets where direct alignment is impossible. The flexible u-joint allows mechanics to reach these tight spots with ease, reducing the need to remove surrounding parts.

Time and Effort Savings

Using a u joint impact socket can significantly reduce the time and effort required for repairs and maintenance. By allowing access to fasteners in tight spaces, it eliminates the need to disassemble and reassemble surrounding components, making repetitive tasks more efficient. This is especially beneficial in production environments where time is of the essence.

Compatibility with Impact Tools

U joint impact sockets are built to withstand the high torque generated by impact wrenches, making them a reliable choice for heavy-duty applications. Unlike cheaper universal joints that may fail under stress, high-quality u joint impact sockets are designed to handle the rigors of professional use, ensuring longevity and performance.

Common Applications and Use Cases

The versatility of u joint impact sockets makes them suitable for a wide range of applications, from automotive repairs to DIY projects.

Essential Checklist

Goal Definition

Clearly define objectives and success metrics

Resource Planning

Allocate necessary time, budget, and personnel

Implementation Strategy

Develop step-by-step execution plan

Quality Assurance

Establish testing and validation procedures

Performance Monitoring

Set up tracking and reporting systems

Essential items for U Joint Impact Socket

Automotive Repairs and Maintenance

In the automotive industry, u joint impact sockets are indispensable for tasks such as:

- Removing oil pans and transmission mounts

Off-Road and Heavy-Duty Vehicles

Trucks, SUVs, and heavy machinery often have complex undercarriages that make maintenance challenging. U joint impact sockets provide the flexibility needed to access and work on these vehicles, ensuring that repairs can be completed efficiently and effectively.

DIY and Home Garage Projects

Weekend mechanics can also benefit from u joint impact sockets. Whether you’re working on a classic car restoration or a modern vehicle, these sockets make it easier to access hard-to-reach fasteners without the need for specialized tools. They are a valuable addition to any home garage toolkit.

How to Choose the Right U Joint Impact Socket

Selecting the right u joint impact socket depends on your specific needs and the types of tasks you perform. Consider the following factors to make an informed decision:

Drive Size and Socket Dimensions

Match the drive size of the socket to the drive on your impact wrench or ratchet. Common drive sizes include 1/4″, 3/8″, and 1/2″. Additionally, choose socket sizes that correspond to the fasteners you’ll be working with, typically ranging from 8mm to 19mm.

Material and Build Quality

Look for u joint impact sockets made from impact-rated steel, such as chrome molybdenum or chrome vanadium steel. Heat-treated construction and corrosion resistance are also important for durability and longevity. High-quality materials ensure that the socket can withstand the high torque of impact wrenches without breaking.

Degree of Flex and Swivel Range

Most u joint impact sockets offer a 15° to 30° articulation range. The degree of flex and swivel range can affect torque transfer, so consider the trade-offs between flexibility and performance. For most applications, a 20° to 25° range provides a good balance.

Brand and Warranty Considerations

Choose reputable brands known for their quality and reliability, such as Tekton, GearWrench, and Craftsman. Look for products with lifetime warranties, which provide peace of mind and ensure that you can replace the socket if it fails due to manufacturing defects.

Proper Usage and Safety Tips

To get the most out of your u joint impact socket and ensure its longevity, follow these usage and safety tips:

Correct Torque Application

Avoid over-torquing beyond the tool’s specifications. Use a variable-speed impact wrench to control the torque and prevent damage to the fastener or the socket. Always check the manufacturer’s recommendations for torque settings.

Maintaining Alignment and Stability

Do not use the u joint impact socket at extreme angles under full load. Keep the socket seated properly on the fastener to maintain stability and prevent the u-joint from breaking. Proper alignment ensures efficient torque transfer and reduces the risk of tool damage.

Regular Inspection and Maintenance

Inspect your u joint impact socket regularly for signs of wear, such as cracks, worn u-joints, or rounded fasteners. Clean and lubricate the moving parts to keep the socket in optimal condition. Proper maintenance extends the life of the tool and ensures it continues to perform reliably.

Top U Joint Impact Socket Products on the Market

Here are some of the top-rated u joint impact socket products available on the market, each offering unique features and benefits:

Tekton 23513 3/8-Inch Drive U-Joint Impact Socket Set

The Tekton 23513 3/8-inch drive u-joint impact socket set is a durable and affordable option that is widely praised for its smooth articulation. It includes a range of socket sizes to fit various fasteners and is built to withstand the high torque of impact wrenches. The heat-treated construction and corrosion-resistant finish ensure long-lasting performance.

GearWrench 80546 1/2-Inch Drive 18mm U-Joint Impact Socket

The GearWrench 80546 1/2-inch drive 18mm u-joint impact socket is designed for high-torque applications and features a patented design that reduces wobble and enhances stability. Its professional-grade construction and impact-rated materials make it a reliable choice for automotive and industrial repairs. The 18mm size is ideal for working with larger fasteners in tight spaces.

Sunex 1754 1/2-Inch Drive 14mm Flex-Head Impact Socket

The Sunex 1754 1/2-inch drive 14mm flex-head impact socket is a professional-grade tool used in auto shops and by mechanics. It offers excellent durability and is built to withstand the rigors of heavy-duty applications. The 14mm size is versatile and suitable for a wide range of fasteners, making it a valuable addition to any toolkit.

Frequently Asked Questions (FAQ)

Can I use a u joint impact socket with a regular ratchet?

Yes, you can use a u joint impact socket with a regular ratchet, but it is optimized for use with impact tools. Using it with a hand ratchet is safe but may not fully utilize its flexibility and torque capabilities.

Are u joint impact sockets as strong as straight sockets?

High-quality u joint impact sockets are impact-rated and strong, but torque transfer is slightly less efficient at angles. They are designed to handle high torque, making them suitable for most automotive and industrial applications.

How do I prevent the u joint from breaking under high torque?

Avoid using the u joint impact socket at extreme angles under full load. Regularly inspect the u-joint for signs of wear and replace the socket if necessary. Proper alignment and maintenance are key to preventing breakage and ensuring the tool’s longevity.

Can u joint sockets be used in high-vibration environments?

Yes, u joint impact sockets can be used in high-vibration environments if they are impact-rated. Non-impact universal joints may loosen or fail under these conditions, so it’s important to choose a tool designed for high-torque applications.

Do u joint impact sockets work with torque wrenches?

U joint impact sockets are not recommended for use with torque wrenches due to the angle introduced by the u-joint, which can affect torque accuracy. Use them only for loosening or with hand tools for final tightening to ensure precise torque settings.

Conclusion – Why Every Mechanic Should Own a U Joint Impact Socket

The u joint impact socket is a versatile and time-saving tool that every mechanic and DIY enthusiast should have in their toolkit. Its ability to access tight spaces, reduce the need for disassembly, and work seamlessly with impact wrenches makes it an invaluable asset in modern automotive and industrial repairs. By investing in a high-quality u joint impact socket, you can ensure that your tools are up to the task, providing the reliability and performance you need to tackle even the most challenging jobs. Whether you’re a professional mechanic or a weekend warrior, a u joint impact socket is a must-have tool that will enhance your efficiency and effectiveness in the garage. Always prioritize safety, durability, and proper tool selection to get the most out of this essential piece of equipment.