Universal Joint Socket Impact

The universal joint socket impact is a powerhouse tool that often goes unnoticed, yet it’s indispensable for tackling tough jobs in tight spots. From automotive repairs to construction projects, this adaptable tool delivers the torque you need with the flexibility to reach otherwise inaccessible fasteners. Understanding its capabilities and proper usage can significantly improve efficiency and safety on the job.

Introduction to Universal Joint Socket Impact

The universal joint socket impact is a crucial tool in various industries, including automotive, construction, and engineering. This versatile tool combines the power of an impact wrench with the flexibility of a universal joint, allowing users to access and manipulate fasteners in confined or awkward spaces. This article provides a comprehensive overview of the universal joint socket impact, its applications, benefits, and usage guidelines.

What is a Universal Joint Socket Impact?

Definition and Explanation

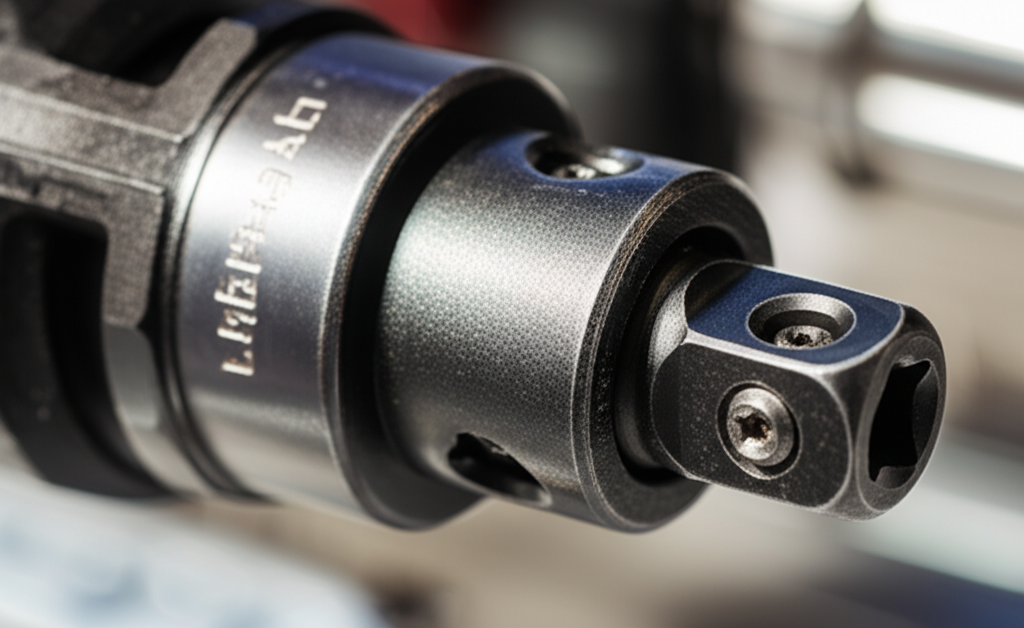

A universal joint socket impact is a specialized socket designed for use with impact wrenches or impact drivers. It incorporates a universal joint, also known as a U-joint, which allows the socket to pivot and rotate. This flexibility enables the tool to reach fasteners at an angle or in tight spaces where a standard socket cannot fit. These sockets are typically made of hardened steel to withstand the high torque generated by impact tools. They come in various drive sizes (e.g., 1/4″, 3/8″, 1/2″) to match different impact wrench sizes.

Different types include standard universal joint impact sockets, swivel impact sockets, and extensions with integrated universal joints. The choice depends on the specific application and the degree of flexibility required.

Key Features and Benefits

The key feature of a universal joint socket impact is its ability to provide flexibility in tight spaces. This allows users to access fasteners that would otherwise be impossible to reach without disassembling surrounding components. Benefits include increased torque transfer compared to using standard sockets with separate universal joint adapters, improved efficiency, and reduced user fatigue. The integrated design minimizes the risk of slippage and ensures a more secure connection.

Compared to traditional socket impacts, universal joint socket impacts provide greater accessibility and maneuverability, making them ideal for complex tasks. They also reduce the risk of damaging surrounding components by allowing for more controlled and precise movements.

Applications of Universal Joint Socket Impact

Industrial Applications

Universal joint socket impacts are widely used in automotive repair for tasks such as removing exhaust manifold bolts, accessing suspension components, and working on engine bays. In construction, they are valuable for tightening bolts in structural frameworks and accessing fasteners in confined areas. Engineering applications include machinery maintenance, equipment assembly, and working on complex mechanical systems. For example, a mechanic might use one to reach a stubborn bolt behind an engine block without having to remove the entire engine.

Progress Overview

Progress analysis for Universal Joint Socket Impact

DIY and Home Improvement Applications

For DIY enthusiasts and homeowners, universal joint socket impacts are useful for a variety of projects. These include assembling furniture, repairing appliances, and working on automotive maintenance tasks. They are particularly helpful when dealing with projects that require tightening or loosening bolts and nuts in tight spaces, such as under sinks or inside appliances. Imagine trying to fix a leaky faucet where the shut-off valve is awkwardly positioned – a universal joint socket impact can be a lifesaver.

How to Use a Universal Joint Socket Impact

Safety Precautions

When using a universal joint socket impact, always wear appropriate personal protective equipment (PPE), including safety glasses and gloves. Ensure the workpiece is securely supported to prevent movement during operation. Maintain a stable stance and avoid overreaching or working in awkward positions. Proper ventilation is important, especially when working in enclosed spaces.

Step-by-Step Guide

1. Choose the Right Socket Size: Select the socket size that matches the fastener you are working on. Refer to the manufacturer’s guidelines for socket size recommendations.

2. Attach the Socket to the Impact Gun: Securely attach the universal joint socket impact to the impact gun, ensuring it clicks or locks into place.

3. Position the Socket: Carefully position the socket onto the fastener, ensuring it is fully seated.

4. Operate the Impact Gun: Start the impact gun and apply steady pressure to tighten or loosen the fastener. Avoid excessive force, which can damage the socket or the fastener.

5. Monitor Performance: Periodically check the socket and the fastener for wear and tear. If any issues arise, stop immediately and address the problem.

Maintenance and Troubleshooting

Maintenance Tips

Regularly clean the universal joint socket impact with a clean cloth to remove dirt, grease, and debris. Lubricate the universal joint with a suitable lubricant to ensure smooth operation. Inspect the socket for wear and tear, such as cracks or deformation. Store the tool in a dry, protected environment to prevent corrosion. Checking the tool for wear and tear before each use is a good habit to develop.

Troubleshooting Common Issues

Socket slippage can occur if the socket is not properly seated on the fastener or if the impact gun is used at an incorrect angle. Ensure the socket is fully seated and adjust the angle of the impact gun as needed. Impact gun malfunction can be caused by low battery power or mechanical issues. Check the battery charge and inspect the impact gun for any visible damage. If the fastener is too tight, try using a penetrating oil to loosen it before attempting to remove it with the impact gun. If problems persist, consult a qualified technician.

Conclusion

In conclusion, the universal joint socket impact is a versatile and essential tool that offers numerous benefits and applications in various industries. Its flexibility and torque delivery make it indispensable for tackling tough jobs in tight spots. By following the guidelines and safety precautions outlined in this article, users can maximize the effectiveness of their universal joint socket impact and achieve their project goals efficiently and safely.

FAQ

- What is the difference between a universal joint socket impact and a traditional socket impact?

- How do I choose the right socket size for my universal joint socket impact?

The socket size should be chosen based on the specific application and the size of the bolt or nut being worked on. It’s essential to refer to the manufacturer’s guidelines for socket size recommendations.

- Can I use a universal joint socket impact with any type of impact gun?

Not all universal joint socket impacts are compatible with all types of impact guns. It’s crucial to check the manufacturer’s specifications to ensure compatibility and optimal performance.

- How often should I maintain my universal joint socket impact?

Regular maintenance is essential to extend the lifespan of the universal joint socket impact. It’s recommended to clean and inspect the tool after each use and perform more thorough maintenance every 3-6 months.

- What are the common safety hazards associated with using a universal joint socket impact?

Common safety hazards include socket slippage, impact gun malfunction, and over-tightening or over-loosening of bolts and nuts. It’s essential to follow safety precautions and guidelines to minimize these risks.

A universal joint socket impact offers increased flexibility and improved torque, making it ideal for applications that require working in tight spaces or with limited access.