Universal Joint Socket Used For

Universal joint sockets are indispensable components in mechanical systems, enabling the transmission of rotational motion between misaligned shafts. Whether in vehicles, industrial machinery, or aerospace applications, these versatile joints ensure smooth power transfer while accommodating angular shifts. However, choosing the right type for a specific task requires understanding their design, functionality, and real-world applications. This guide explores the diverse uses of universal joint sockets, their classifications, and practical selection tips to help engineers, mechanics, and enthusiasts make informed decisions.

What is a Universal Joint Socket?

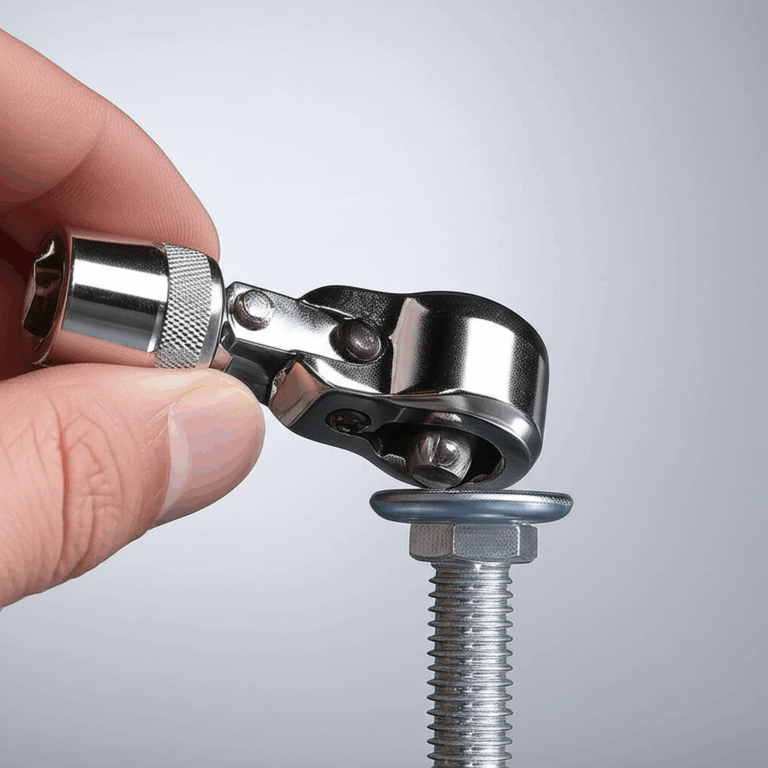

A universal joint socket, or U-joint socket, is a mechanical coupling that transfers torque between two rotating shafts at varying angles. Its core components include two yokes, a cross-shaped bearing (spider), and needle bearings that reduce friction. Unlike rigid couplings, U-joints accommodate misalignment without binding, making them ideal for dynamic environments. The key difference between universal joints and couplings lies in their flexibility—couplings connect coaxial shafts, while U-joints handle angular displacement.

Common Uses of Universal Joint Sockets

Automotive Industry Applications

Universal joint sockets are critical in automobiles, particularly in driveshafts, where they connect the transmission to the differential. They also appear in steering systems and PTO shafts for agricultural machinery, allowing power transfer to implements like plows. Their ability to handle torque fluctuations and misalignment makes them indispensable in vehicles subjected to rough terrain.

Industrial and Manufacturing Uses

In factories, U-joints power conveyor belts, pumps, and compressors by compensating for shaft misalignment caused by thermal expansion or structural shifts. They are also found in robotic arms and automated assembly lines, where precision and adaptability are paramount. By absorbing vibrations and reducing stress on connected machinery, these joints extend equipment lifespan.

Marine and Aerospace Applications

Marine vessels rely on U-joints to drive propeller shafts, while aircraft use them in control systems and helicopter rotor drives. Their compact design and high torque capacity make them suitable for extreme conditions, such as underwater pressure or high-altitude temperatures. In aerospace, corrosion-resistant materials like stainless steel are often used to withstand harsh environments.

Types of Universal Joint Sockets

Single Universal Joint Sockets

Single U-joints consist of one cross bearing and are used in applications requiring limited angular movement. They are common in light-duty machinery like lawnmowers and small conveyors, where simplicity and cost-efficiency are prioritized. However, they introduce a slight rotational speed variation between input and output shafts.

Double Universal Joint Sockets

Double U-joints feature two cross bearings and are designed to eliminate speed variations caused by angular misalignment. They are essential in high-performance applications like racing vehicles and industrial drivetrains, where consistent power delivery is critical. Their compact design also minimizes space constraints in tight installations.

Cardan Joint Sockets

Cardan joints are a specialized type of U-joint that provides better load distribution and reduced wear. They are often used in high-torque systems like mining equipment and marine propulsion. Unlike standard U-joints, they are less prone to binding, making them ideal for applications with extreme misalignment.

How to Select the Right Universal Joint Socket

Choosing the appropriate U-joint involves evaluating load capacity, operational speed, and misalignment angles. Steel U-joints offer high strength, while aluminum versions reduce weight for aerospace or automotive use. Ensure compatibility with existing equipment by checking shaft diameters and mounting configurations. Consult manufacturer specifications to avoid overloading or premature failure.

Maintenance and Troubleshooting

Regular lubrication with high-quality grease is essential to prevent bearing wear and overheating. Inspect U-joints for cracks, excessive play, or vibration during routine maintenance. Replace damaged components immediately to avoid costly downtime. If a joint fails prematurely, investigate causes like improper installation or environmental contamination.

Conclusion

Universal joint sockets are vital for transmitting rotational power in misaligned systems, with applications spanning automotive, industrial, and aerospace sectors. Understanding their types, uses, and maintenance requirements empowers professionals to optimize performance and reliability. Whether upgrading machinery or troubleshooting issues, selecting the right U-joint ensures efficiency and longevity in demanding environments.

FAQs

Q1: Can a universal joint socket be used in high-speed applications?

Yes, but speed ratings vary; consult manufacturer specifications.

Q2: How often should universal joint sockets be inspected?

Regularly during routine maintenance, especially in heavy-duty applications.

Q3: Are universal joint sockets interchangeable between different brands?

Not always; check dimensions, torque ratings, and compatibility.

Q4: What causes premature failure in universal joint sockets?

Lack of lubrication, excessive misalignment, or overloading.

Q5: Can universal joint sockets be repaired or modified?

Minor repairs (e.g., bearing replacement) may be possible, but major modifications are not recommended.