U Joint for Socket

Universal joints (U joints) are the unsung heroes of mechanical systems, enabling smooth power transmission between misaligned shafts in everything from cars to industrial machinery. Among their various designs, socket-style U joints stand out for their durability and ease of installation. Whether you’re a mechanic, engineer, or DIY enthusiast, choosing the right U joint for socket applications is crucial for performance and longevity. This guide breaks down everything you need to know—from types and applications to installation tips and maintenance best practices—so you can make informed decisions and keep your systems running smoothly.

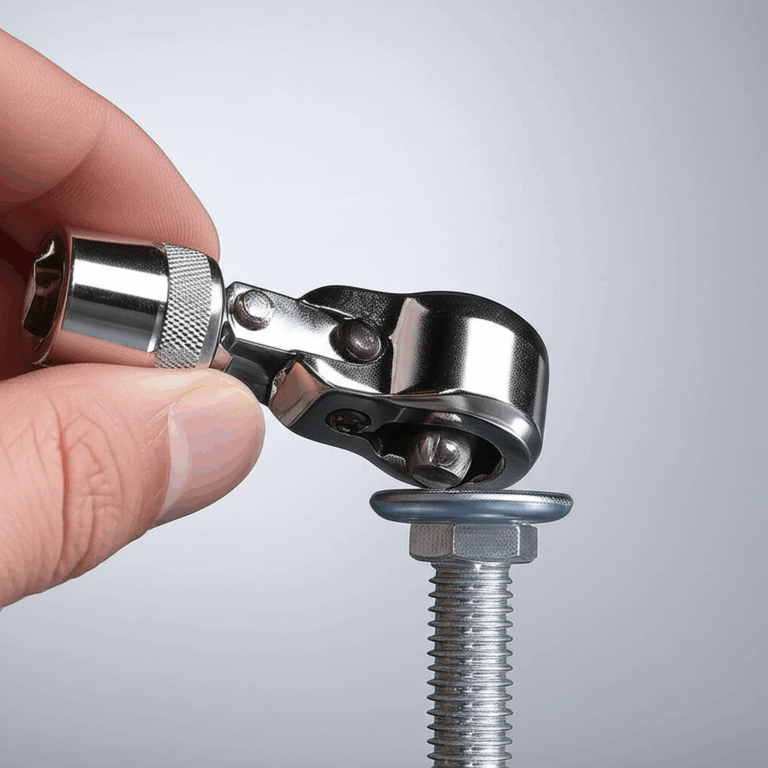

Step-by-Step Process

Inspect the Socket

Check for damage, wear, or misalignment in the socket.

Clean the Components

Remove dirt and debris from the socket and U-joint.

Apply Lubrication

Use grease on the bearing surfaces for smooth operation.

Insert the U-Joint

Align and press the U-joint into the socket securely.

Test for Proper Fit

Ensure the U-joint moves freely without binding.

Process infographic for U Joint for Socket

Understanding U Joints for Sockets

What Is a U Joint for a Socket?

A U joint for a socket is a type of universal joint that connects rotating shafts at an angle, allowing for misalignment while transmitting torque efficiently. It consists of a cross (or spider) with needle bearings pressed into the fork yokes and secured with grease-fittings caps. The “socket” design refers to the way the joint attaches to the shaft, providing a secure and adjustable fit. These joints are essential in applications where shafts cannot be perfectly aligned, such as in vehicle drivelines or industrial machinery.

Types of U Joints for Sockets

Not all U joints are created equal. Here are the most common types:

- Cardan U joints: The most widely used type, featuring a simple cross design for reliable torque transmission in automotive and industrial applications.

- Constant-velocity (CV) U joints: These minimize vibration and maintain consistent rotational speed, making them ideal for high-performance applications.

- Single vs. double U joints: Single U joints are simpler and more compact, while double U joints (also called double-cardan joints) reduce vibration and accommodate larger misalignments.

Common Applications of Socket-Style U Joints

Socket-style U joints are versatile and found in various industries:

- Automotive: Used in drivelines for trucks, cars, and agricultural machinery to connect the transmission to the driveshaft.

- Industrial: Power conveyor systems, pumps, and fans where misaligned shafts require flexible connections.

- Marine and aerospace: Designed to withstand harsh environments and high loads in propulsion systems.

Selecting the Right U Joint for Sockets

Key Factors to Consider When Choosing a U Joint

Selecting the wrong U joint can lead to premature failure or system inefficiency. Consider these factors:

- Load capacity: Ensure the joint can handle the torque and rotational forces in your application.

- Misalignment tolerance: Choose a joint that accommodates the expected angular or parallel misalignment.

- Material: Stainless steel is corrosion-resistant, while composite materials may be lighter but less durable.

- Size and compatibility: Verify that the joint fits your shaft dimensions and socket specifications.

How to Measure a U Joint for Proper Fitment

Accurate measurements are critical for a perfect fit. Measure the following:

- The diameter of the journals (the ends of the cross)

- The bearing capacity (the size of the needle bearings)

- The shaft size and socket dimensions where the joint will attach

Misalignment issues can arise if the joint is too large or small for the application.

Premium Brands & Where to Buy U Joints for Sockets

Quality matters when it comes to U joints. Trusted brands include:

- SPI: Known for heavy-duty industrial U joints

- Neapco: A leader in automotive driveline components

- GKN: Specializes in high-performance U joints for various industries

Purchase from authorized dealers or reputable online retailers to ensure authenticity.

Installation & Maintenance of U Joints for Sockets

Step-by-Step Guide to Installing a Socket U Joint

Follow these steps for a smooth installation:

- Gather tools: socket wrench, grease gun, alignment tools, and safety gear.

- Remove the old U joint carefully to avoid damaging nearby components.

- Apply high-quality grease to the needle bearings before installation.

- Secure the joint in place, ensuring proper alignment with the shafts.

Common Installation Mistakes & How to Avoid Them

Mistakes during installation can lead to premature wear. Avoid these pitfalls:

- Over-tightening: This can damage bearings or cause misalignment.

- Under-lubrication: Insufficient grease leads to friction and overheating.

- Misalignment: Even slight misalignment increases stress on the joint.

Maintenance Tips for Prolonging U Joint Lifespan

Regular maintenance extends the life of your U joint:

- Lubricate every 3-6 months or as recommended by the manufacturer.

- Inspect for wear, such as clicking noises or excessive play.

- Replace the joint if you notice grease leakage or severe damage.

Troubleshooting U Joint Problems in Socket Applications

If your U joint is causing issues, here’s how to diagnose and fix common problems:

- Vibration: Check for misalignment or damaged bearings.

- Unusual noises: Grinding or clicking may indicate bearing failure.

- Grease leakage: Replace seals or ensure proper lubrication.

- Premature failure: Overloading or poor alignment are likely causes.

Conclusion

U joints for sockets are critical components in mechanical systems, ensuring smooth power transmission even when shafts are misaligned. By understanding the different types, selecting the right joint for your application, and following proper installation and maintenance practices, you can maximize performance and longevity. Whether you’re working on a vehicle, industrial machinery, or marine equipment, investing in quality U joints and maintaining them correctly will save you time and money in the long run.

FAQs About U Joints for Sockets

Q1: How often should I grease my U joint for a socket?

Grease your U joint every 3-6 months or as recommended by the manufacturer to prevent wear.

Q2: Can a U joint for a socket be repaired, or should it be replaced?

Minor wear can sometimes be fixed, but severe damage requires full replacement for safety and performance.

Q3: What causes a U joint to fail prematurely?

Premature failure is often due to lack of lubrication, misalignment, overloading, or low-quality materials.

Q4: Are all socket U joints universal, or do they vary by application?

No, they vary based on size, load capacity, and environmental conditions—always check compatibility.

Q5: How do I know if my U joint is properly aligned?

Proper alignment means minimal vibration and smooth operation when the system is running.