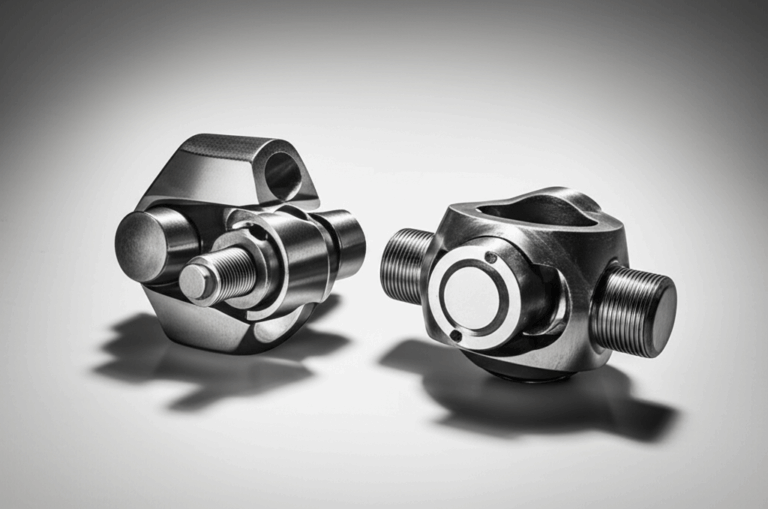

Universal Joint for Socket Set

When working on automotive repairs, machinery maintenance, or DIY projects, reaching tight or awkward spaces can be a challenge. That’s where a universal joint for a socket set comes in handy. This flexible tool allows mechanics and DIY enthusiasts to apply torque at angles that standard sockets and extensions can’t handle. Whether you’re loosening a bolt in an engine bay or tightening a fastener in a confined space, a universal joint ensures precision and efficiency. Available in various types and sizes, these joints are designed to enhance versatility and reduce strain on both the tool and the user. In this guide, we’ll explore everything you need to know about universal joints for socket sets, from how they work to choosing the right one for your needs.

Step-by-Step Process

Select the Right Joint

Choose a universal joint compatible with your socket set's drive size.

Align the Components

Ensure the joint and socket are properly aligned for smooth operation.

Secure the Connection

Tighten the joint securely to prevent slippage during use.

Test the Functionality

Rotate the joint to verify smooth movement and proper fit.

Lubricate as Needed

Apply grease to reduce friction and extend the joint's lifespan.

Process infographic for Universal Joint for Socket Set

What is a Universal Joint for a Socket Set?

A universal joint (U-joint) for a socket set is a mechanical coupling that allows rotational movement between two shafts at varying angles. Unlike standard extensions, which require a straight alignment, a U-joint enables torque transmission even when the socket is at an angle. This makes it indispensable for automotive work, industrial repairs, and tight-space applications. While standard sockets and extensions work well in open areas, a U-joint ensures flexibility where space is limited.

How Universal Joints Work in Socket Sets

Mechanism of a Universal Joint

A universal joint operates using a cross-shaped mechanism (also called a “cross yoke” or “spider”) that connects two rotating shafts. The cross allows the shafts to pivot at different angles while maintaining torque transfer. As one end of the joint rotates, the other end follows at the same speed but at a different angle. Key components include:

- Cross (or spider): The central pivot point that allows angular movement.

- Yoke: Connects the cross to the shaft or socket.

- Bearings: Reduce friction and ensure smooth rotation.

Advantages of Using a Universal Joint with Socket Sets

Using a universal joint offers several benefits, including:

- Access to Tight Spaces: Lets you reach bolts and fasteners in cramped or awkward positions.

- Reduced Strain: Minimizes the need for awkward hand positions, reducing fatigue.

- Precision: Ensures accurate torque application even at angles.

Types of Universal Joints for Socket Sets

Standard Universal Joint (U-Joint)

The most common type, a standard U-joint, provides reliable torque transmission at moderate angles. It’s ideal for general automotive and mechanical work, offering durability and ease of use. However, it may not handle extreme angles as effectively as other types.

Flexible Universal Joint

Designed for greater flexibility, this type allows for sharper angles and tighter spaces. It’s perfect for situations where the standard U-joint struggles, such as deep within an engine or around obstructions.

Quick-Release Universal Joint

Featuring a fast-attach mechanism, this type allows for quick socket changes. It’s particularly useful in settings where efficiency is key, such as assembly lines or rapid repair tasks.

Factors to Consider When Choosing a Universal Joint for Your Socket Set

Selecting the right universal joint depends on several factors:

- Material & Durability: Chrome vanadium steel offers high strength and corrosion resistance.

- Size & Compatibility: Ensure it matches your socket set’s drive size (e.g., 1/4″, 3/8″, 1/2″).

- Torque Capacity: Choose one that aligns with your tool’s maximum torque.

- Brand & Quality: Opt for reputable brands to ensure reliability.

How to Use a Universal Joint with a Socket Set

Using a universal joint is straightforward:

- Attach the U-joint to your ratchet or breaker bar.

- Connect the socket to the other end of the U-joint.

- Position the socket at the desired angle and apply torque.

For maintenance, keep the joint clean and lubricated. Avoid exceeding torque limits to prevent damage.

Troubleshooting Common Issues with Universal Joints

If your U-joint becomes stiff or wobbly, check for:

- Stiff Movement: Lack of lubrication or debris buildup; clean and lubricate the joint.

- Excessive Play: Worn bearings; replace the joint if necessary.

- Premature Wear: Overloading or improper use; select the right joint for your application.

Conclusion

A universal joint is an essential tool for anyone working with socket sets, providing flexibility and precision in tight spaces. Whether you opt for a standard, flexible, or quick-release design, choosing the right joint ensures efficiency and durability. By understanding how they work and maintaining them properly, you can extend their lifespan and enhance your toolkit’s versatility. For the best results, match the joint to your drive size and torque needs, and always prioritize quality for long-term performance.

FAQs

1. Can a universal joint be used with any type of socket set?

Compatibility depends on the drive size (e.g., 1/4″, 3/8″). Ensure the U-joint matches your socket set’s specifications.

2. How do I know if my universal joint is worn out?

Signs include excessive play, stiffness, or difficulty turning. Replace it if these issues persist.

3. Is a universal joint necessary for DIY work?

It’s beneficial for tight spaces but may not be essential for simple tasks where a standard extension suffices.

4. Can a universal joint be used in high-torque applications?

Check the torque rating; some models handle high torque, while others are better suited for lighter tasks.

5. How do I maintain my universal joint for long-term use?

Clean it regularly, lubricate moving parts, and store it in a dry place to prevent rust and wear.