Double Universal Joint Socket

In the world of mechanical engineering and industrial applications, precision and flexibility are key. One component that exemplifies this balance is the double universal joint socket (DUJS). These versatile couplings are essential for transmitting torque between two shafts that are not perfectly aligned, ensuring smooth operation in everything from automotive drivetrains to complex robotics. Whether you’re a mechanical engineer, a DIY enthusiast, or an industrial professional, understanding the ins and outs of DUJS can help you optimize performance and extend the lifespan of your machinery.

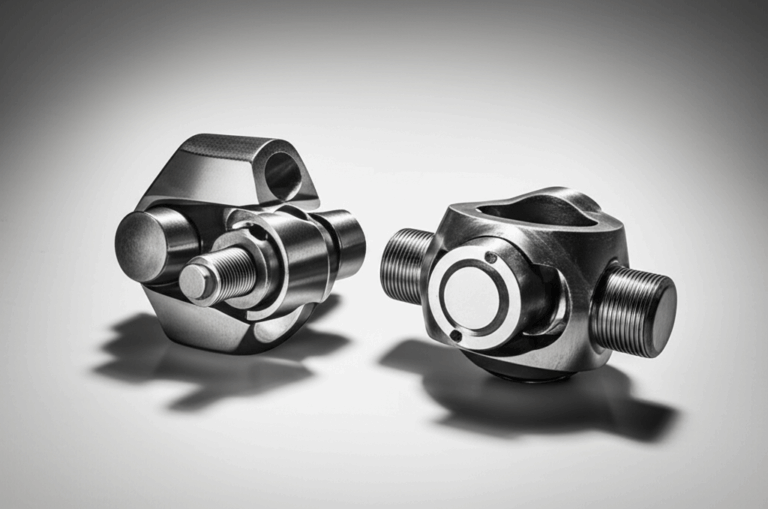

What is a Double Universal Joint Socket?

A double universal joint socket (DUJS) is a mechanical coupling that allows for the transmission of rotational power between two shafts at varying angles. Unlike single universal joints, which have one pivot point, a DUJS features two articulated joints, providing greater flexibility and smoother operation. The socket component of the joint connects the U-joint to the shaft, ensuring secure attachment and efficient torque transfer.

DUJS are widely used in industries such as automotive, aerospace, and industrial automation, where misalignment between shafts is common. Their ability to compensate for angular deviations makes them indispensable in applications where precision and durability are critical.

Types of Double Universal Joint Sockets

Double universal joint sockets come in various designs, each suited for specific applications. Understanding the differences can help you choose the right component for your needs.

Standard vs. Heavy-Duty DUJS

Standard DUJS are typically made from high-grade steel or alloy and are suitable for moderate load applications. Heavy-duty versions, on the other hand, are constructed from reinforced materials like stainless steel or high-carbon alloys, offering superior strength and durability for high-torque environments.

Fixed vs. Flexible Sockets

Fixed sockets provide a rigid connection, ideal for applications where minimal movement is required. Flexible sockets, however, allow for greater articulation, making them perfect for systems that demand dynamic adjustments, such as robotic arms or agricultural machinery.

Threaded vs. Clamp-Style Sockets

Threaded sockets are secured with bolts, offering a permanent and robust connection. Clamp-style sockets, meanwhile, use adjustable clamps to fasten the joint, allowing for easier installation and removal. The choice between the two depends on the specific requirements of your application.

Key Features to Consider When Choosing a DUJS

Selecting the right double universal joint socket involves evaluating several critical factors to ensure optimal performance.

- Torque and Speed Ratings: Match the DUJS to the operational torque and speed of your system to prevent premature failure.

How to Install and Align a Double Universal Joint Socket

Proper installation and alignment are crucial for the longevity of a DUJS. Follow these steps to ensure a seamless setup:

- Clean the shaft and socket surfaces to remove debris.

Misalignment can lead to excessive wear, vibration, and reduced efficiency, so precision is key.

Maintenance and Troubleshooting Tips for DUJS

Regular maintenance extends the life of your DUJS and prevents costly downtime. Here’s what you need to know:

- Lubrication: Apply grease or oil at recommended intervals to reduce friction and wear.

Advantages of Using Double Universal Joint Sockets

DUJS offer several benefits over other coupling mechanisms, making them a preferred choice in many industries:

- Enhanced flexibility for accommodating misaligned shafts.

Conclusion

Double universal joint sockets are indispensable components in mechanical systems, providing the flexibility and durability needed for efficient torque transmission. By understanding the different types, installation best practices, and maintenance requirements, you can ensure optimal performance and longevity. For complex applications, consulting with a mechanical expert can help you select the right DUJS for your specific needs.

FAQ Section

1. What is the difference between a single and double universal joint socket?

Comparison table for 1. What is the difference between a single and double universal joint socket?

Single universal joints have one pivot point, while double universal joints feature two, allowing for greater articulation and smoother torque transfer across misaligned shafts.

2. How often should I lubricate a double universal joint socket?

Lubrication frequency depends on usage, but a general guideline is every 3 to 6 months for moderate applications and more frequently for high-demand systems.

3. Can a DUJS be used in high-temperature environments?

Yes, but ensure the socket is made from heat-resistant materials like stainless steel or high-temperature alloys to prevent degradation.

4. What are the signs of a failing double universal joint socket?

Common signs include knocking sounds, excessive play, misalignment, and increased vibration during operation.

5. Are all DUJS compatible with standard shafts?

No, compatibility depends on shaft size, spline type, and connection method. Always verify specifications before purchase.