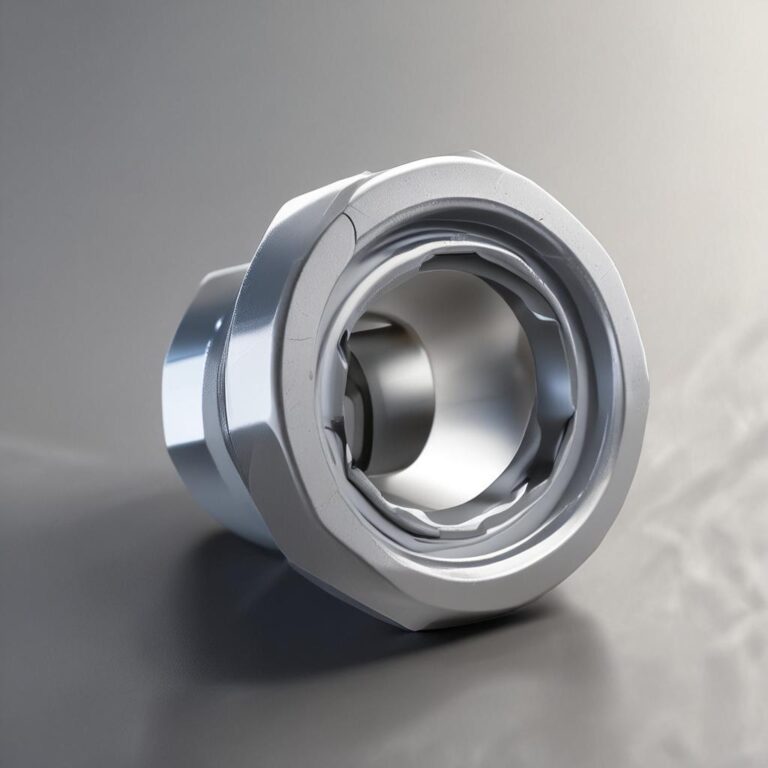

1 2 Inch Universal Joint Socket

In the world of automotive repair, mechanical maintenance, and DIY projects, having the right tools can make all the difference. One such tool that stands out for its flexibility and utility is the 1 2 inch universal joint socket. Designed to tackle nuts and bolts in awkward positions, this socket is a must-have for professionals and hobbyists alike. Whether you’re working on a car engine, assembling furniture, or maintaining industrial machinery, understanding the role and advantages of this tool can enhance your efficiency and precision. This guide dives into the details of the 1 2 inch universal joint socket, exploring its uses, benefits, and how to choose the best one for your needs.

What is a 1 2 Inch Universal Joint Socket?

Definition and Functionality

A 1 2 inch universal joint socket is a specialized tool that combines a standard socket with a flexible joint mechanism. This joint allows the socket to pivot and adjust angles, making it ideal for accessing nuts and bolts in confined or irregularly shaped spaces. Unlike traditional sockets, which require a straight alignment, the universal joint socket bends to accommodate obstacles, ensuring a secure fit even in challenging environments.

Key Components

The socket consists of three main parts: the socket head (available in various sizes), the universal joint (which enables movement), and the 1 2 inch drive size that connects to ratchets or wrenches. The joint itself is typically a four-point ball-and-socket design, providing smooth articulation without compromising torque transmission.

Types of Universal Joint Sockets

Universal joint sockets come in different sizes, including 3/8 inch and 1/4 inch drives, each suited for specific tasks. The 1 2 inch variant is favored in heavy-duty applications due to its ability to handle higher torque. Additionally, some models feature extended necks or offset heads for even greater accessibility.

Applications of a 1 2 Inch Universal Joint Socket

Automotive Repairs

Automotive technicians rely on this socket to reach fasteners in tight engine compartments, suspension systems, and brake assemblies. For example, it can easily access the cv joint nuts on a vehicle’s driveshaft, where straight sockets would struggle to fit.

Industrial Maintenance

In industrial settings, the socket is essential for servicing machinery with complex configurations. It helps in tightening or loosening bolts on conveyor systems, hydraulic equipment, or pumps, where spatial constraints are common.

DIY Projects

For home users, the 1 2 inch universal joint socket simplifies tasks like assembling IKEA furniture, fixing plumbing, or working on lawnmowers. Its adaptability allows you to work around obstacles without disassembling surrounding components.

Key Metrics

Performance metrics for 1 2 Inch Universal Joint Socket

Benefits of Using a 1 2 Inch Universal Joint Socket

Versatility

The socket’s ability to bend and pivot at multiple angles makes it a versatile solution for tasks that demand precision in tight spaces. This adaptability reduces the need for multiple specialized tools.

Durability

Manufactured from high-grade chrome vanadium steel, these sockets resist deformation and wear, even under heavy use. Their heat-treated construction ensures they maintain strength and reliability over time.

Efficiency

By allowing access to hard-to-reach areas, the universal joint socket minimizes the time spent adjusting tools or disassembling parts. This efficiency is crucial in both professional workshops and personal projects.

How to Choose the Right 1 2 Inch Universal Joint Socket

Material Quality

Opt for sockets made from hardened steel to ensure they withstand high torque and frequent use. A polished finish also reduces friction and prevents rust, extending tool life.

Compatibility

Verify that the socket’s 1 2 inch drive matches your ratchet or wrench. Some models offer additional features like a 15-degree offset, which can be beneficial for specific applications.

Brand and Price

While budget-friendly options exist, investing in a reputable brand like Craftsman or Snap-on guarantees better craftsmanship. Compare prices and read user reviews to balance quality with cost-effectiveness.

Tips for Using a 1 2 Inch Universal Joint Socket Safely

Proper Handling

Avoid over-tightening the socket onto a bolt, as this can strain the joint and lead to slippage. Use steady pressure and ensure the socket is fully seated before applying torque.

Maintenance

After each use, clean the socket with a dry cloth to remove debris. Apply a light lubricant to the joint periodically to maintain smooth movement and prevent corrosion.

Safety Precautions

Always inspect the socket for wear before use. A damaged joint can cause the tool to fail, posing a risk of injury. Use the correct size socket for the fastener to avoid stripping or rounding edges.

Conclusion

The 1 2 inch universal joint socket is a versatile, durable, and efficient tool that simplifies tasks across automotive, industrial, and DIY domains. Its unique design allows users to overcome spatial challenges with ease, making it an invaluable addition to any toolkit. When selecting one, prioritize quality materials and compatibility with your existing tools. Whether you’re a seasoned mechanic or a weekend hobbyist, a reliable universal joint socket can save you time and effort. Explore trusted brands today to find the perfect fit for your needs.

FAQ Section

What is the difference between a universal joint socket and a regular socket?

- A universal joint socket has a flexible joint that allows angular movement, enabling access to tight or misaligned areas. Regular sockets require a straight alignment and cannot pivot.

Can a 1 2 inch universal joint socket be used with any wrench?

- Yes, as long as the wrench or ratchet has a 1 2 inch drive. Check the tool’s specifications to confirm compatibility before use.

What are the most common uses for a 1 2 inch universal joint socket?

- It is frequently used in automotive repairs, industrial equipment maintenance, and DIY tasks involving hard-to-reach nuts and bolts.

How do I maintain my universal joint socket?

- Clean it after use, apply lubricant to the joint regularly, and store it in a dry place to prevent rust. Avoid dropping it to maintain structural integrity.

Are universal joint sockets durable enough for heavy-duty tasks?

- Yes, high-quality models made from chrome vanadium steel are built to handle heavy-duty applications without bending or breaking, even under significant torque.